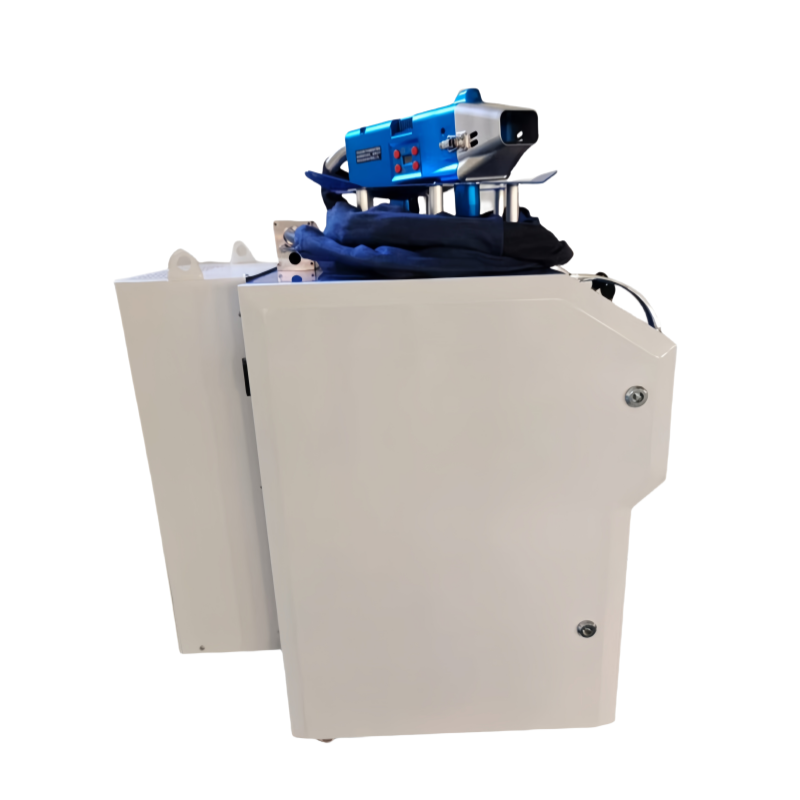

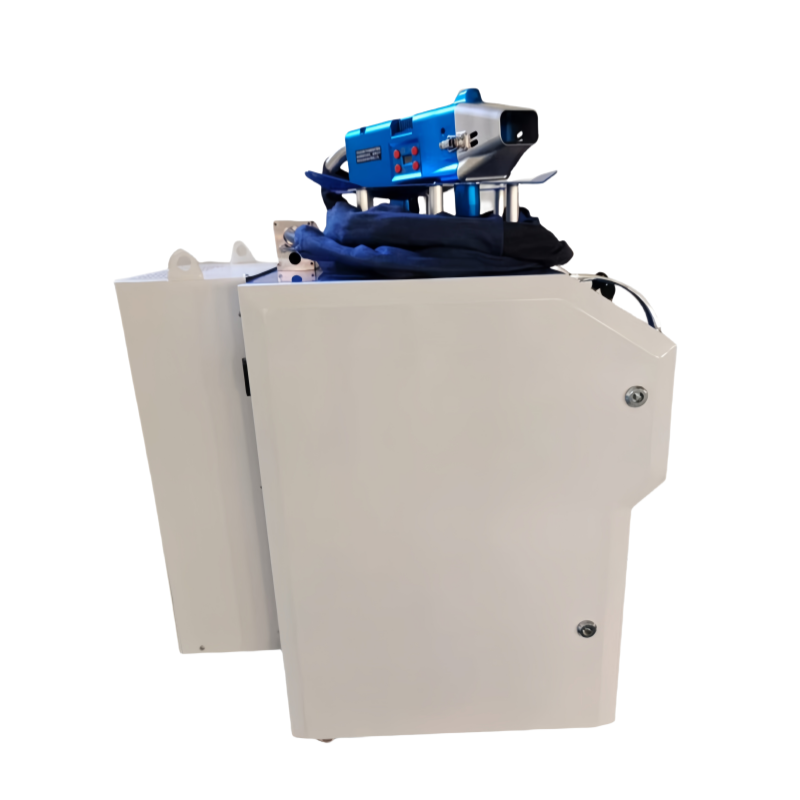

HN-QX50(II) Laser Cleaning Machine:

1. Basic Operating Environment

| Content | Parameter |

| Power Supply Voltage | Single-phase 220V ±10%, 50/60Hz AC |

| Total Power Consumption | < 900W |

| Placement Environment | Flat, vibration-free, no impact |

| Operating Temperature | 0°C to 40°C |

| Operating Humidity | ≤ 80% |

2. Optical Parameters

| Content | Parameter |

| Laser Average Power | 250W |

| Power Instability | < 3% |

| Power Adjustment Range | 0-100% (gradually adjustable) |

| Focusing Spot Diameter | 0.1mm |

| Center Wavelength | 1064nm |

| Modulation Frequency | 67K-400K Hz (gradually adjustable) |

| Fiber Length | 5M |

| Cleaning Mode | 8 modes, freely switchable |

| Cooling Method | Air cooling |

| Operating Temperature | 5°C to 40°C |

Functions and Applications

The HN-QX50(II) Laser Cleaning Machine is ideal for removing contaminants such as rust, paint, oil stains, and oxide films from metal surfaces. With adjustable power settings and a precise optical system, this machine is suitable for delicate cleaning tasks where preserving the integrity of the surface is critical.

Key Functions:

Rust Removal: Effectively eliminates rust from metal surfaces without causing damage.

Paint Removal: Cleans painted surfaces safely, without harming the underlying material.

Oxide Film Removal: Removes oxide layers, enhancing surface quality for further processing.

Oil and Stain Cleaning: Efficiently removes oil stains and other contaminants from metal parts.

Applications:

Metal Surface Cleaning: Ideal for cleaning stainless steel, aluminum, carbon steel, and other metals.

Precision Parts: Perfect for applications requiring precision and surface integrity, such as in aerospace, automotive, and electronics industries.

Maintenance and Repair: Suitable for rust and paint removal in industrial maintenance and repair applications.