3000×1500mm plate cutting 1000W/2000W/3000W 3015 single table series fiber laser cutting machine

1.Features:

Single table tube and plate integrated laser cutting machine

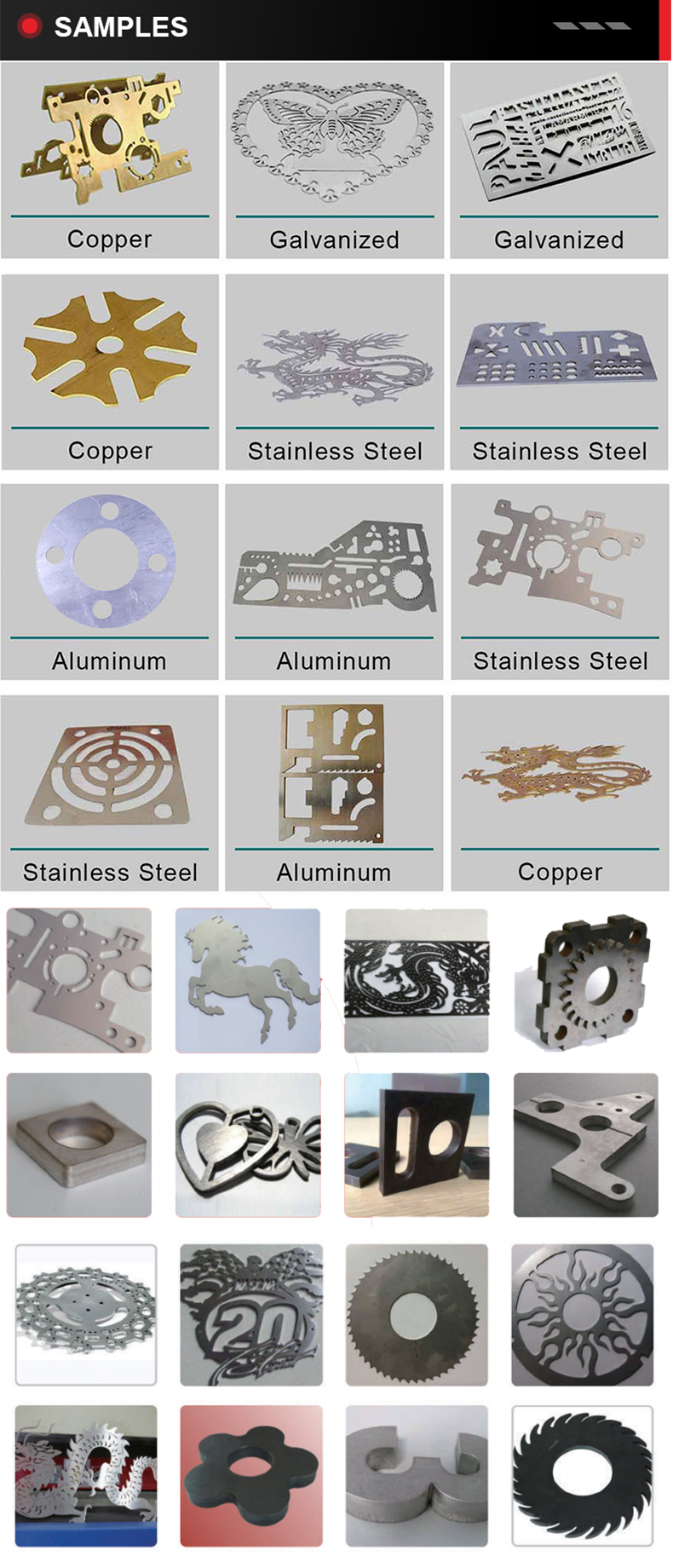

Widely used in automobiles, construction machinery, locomotives, agricultural and forestry machinery, electrical manufacturing, elevator manufacturing, household appliances, food machinery, textile machinery, tool processing, petroleum machinery, food machinery, kitchen and kitchenware, decorative advertisements, laser external processing services , etc. Machinery manufacturing and processing industry.

· High-performance optical fiber transmission, flexible processing, can realize high-quality cutting of any shape, and is suitable for cutting high reflective materials such as copper and aluminum;

· High efficiency, fast cutting speed, low operating cost, double return on your investment;

· Low gas consumption, laser generation requires no gas generation;

· Low energy consumption, energy saving and environmental protection, low power consumption;

· Low maintenance, no reflection lens, no need to adjust the light path, basic maintenance-free;

·A machine can be used for both cutting plates, but also cutting pipes, efficient processing machines.

2. Equipment use:

It can perform non-contact cutting of metal plates and pipes, especially suitable for stainless steel, iron plates, diamond saw blades and other materials, and has excellent processing effect on various high-hard and brittle alloys. Laser cutting technology can partially replace punching and wire cutting in the sheet metal industry. It is mainly used for fast cutting of carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized sheet, pickling sheet, galvanized sheet, copper and other metal materials.

3. Industry application:

Used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway accessories, automobiles, machinery, precision accessories, ships, metallurgical equipment, elevators, household appliances, craft gifts, tool processing, decoration, advertising, metal external processing, etc. Manufacturing industry.

4. Equipment advantages:

(1) The laser cutting speed is fast, the deformation is small, and the precision is high.

(2) Implement international procurement for key components and select brand-name devices to ensure high quality.

Such as: imported rack and pinion transmission system to ensure transmission accuracy Imported brand-name AC servo motor, large torque, fast response.

The laser manufactured by European technology has a unique laser cavity design, which greatly improves the electro-optical conversion efficiency and life, and has high stability.

(3) Advanced structural design, precise machining, complete production process, mature assembly process, and strict testing methods ensure high precision and stable performance of the machine tool.

(4) The CNC numerical control system adopts the optimization algorithm and the opto-mechanical integration design, which fundamentally guarantees the cutting performance.

(5) Powerful software, simple operation and automatic programming. Support DXF, PLT and other graphic formats, strong compatibility.

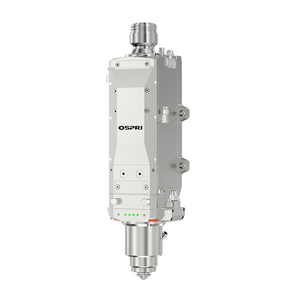

(6) The cutting head adopts advanced capacitive automatic follow-up processing technology, which overcomes the technical problem of uneven focal length change of the plate, and can perform non-contact cutting of metal plates and pipes.

(7) The use and maintenance costs are low, only 1/10 of the high-power CO2 laser cutting machine, and the auxiliary gas can be cut by air, oxygen and nitrogen.

(8) SFL-3015C series, super large format, large format, medium format, small format, flexible selection of various specifications.

(9) An automatic feeding machine can be selected to form a flexible processing system for sheet metal cutting.

5. Equipment parameters:

Laser source type: Fiber source

Laser Out Power: 1070nm

Laser wavelength:1000W/2000W/3000W

Cutting range: 3000×1500mm

Minimum line width:<0.1mm

Transfer method:Precision rack dual drive

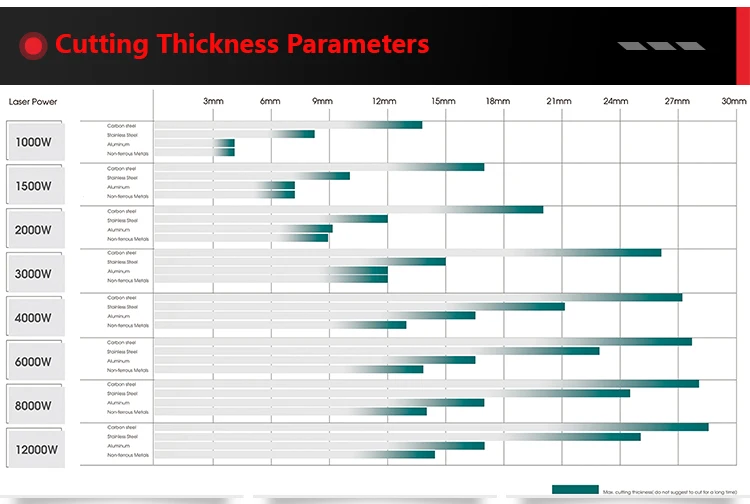

Cutting speed and thickness:Depending on specific material

Repeatability:±0.02mm

Machine operating temperature:0~40℃

Electricity demand: 380V/50Hz

Cooling method:Water cooling

Continuous operating time: 24 hours

Weight:3300KG

Dimensions:4750x2470x1900mm

Maximum operating speed: 120m/min

Maximum acceleration: 0.9G

X/Ypositioning accuracy: 1.2mm

Minimum slit width: 0.15mm