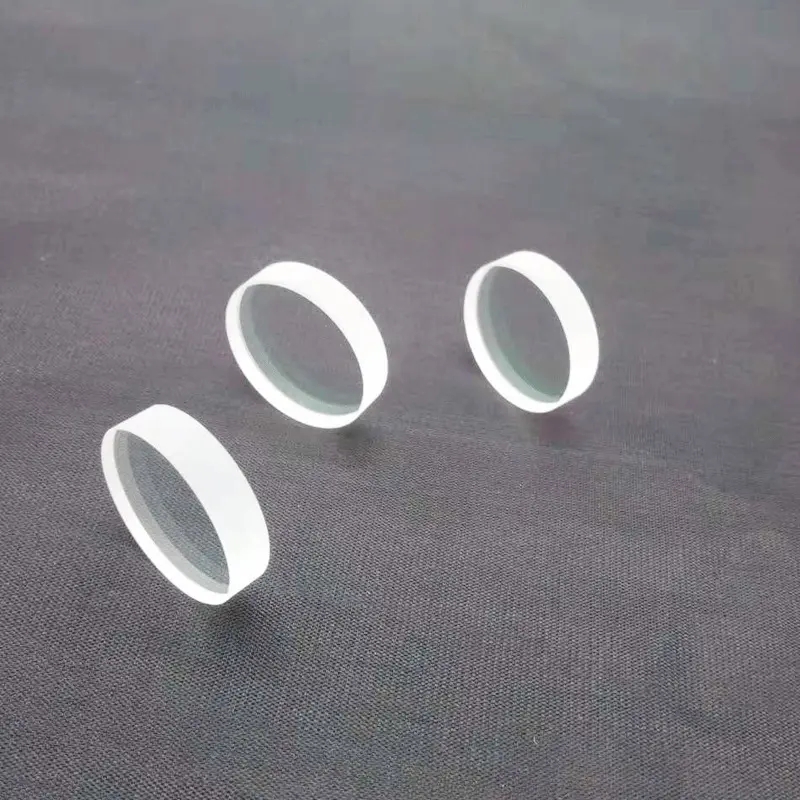

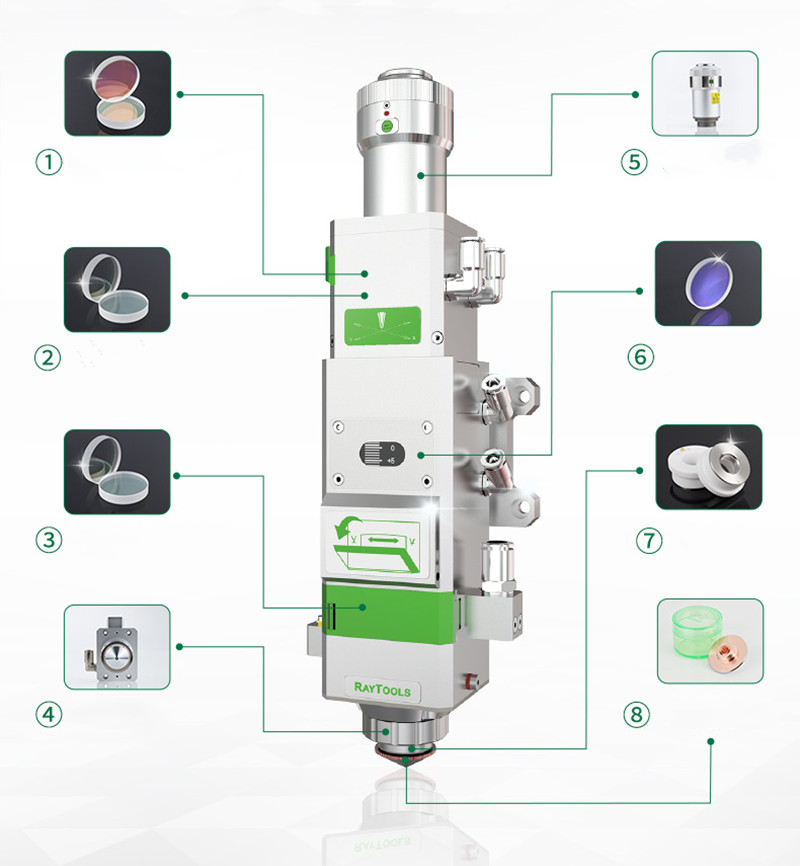

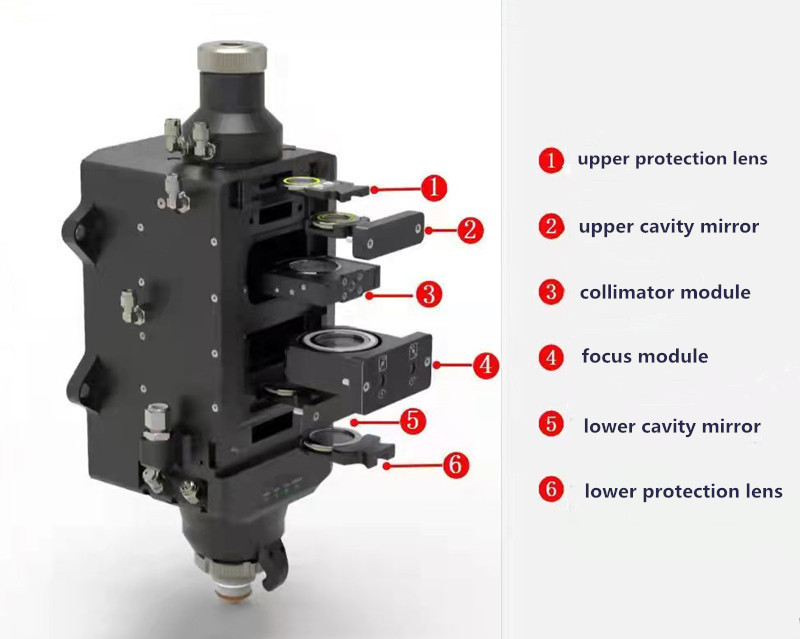

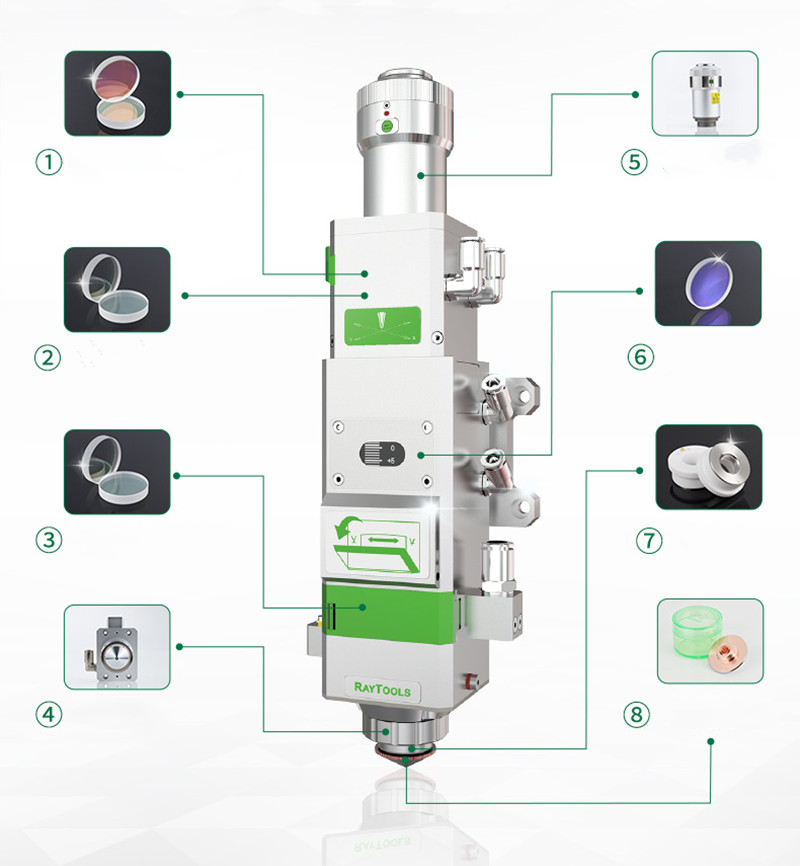

Fiber Laser Protective Lens upper Protection Lens for Fiber Laser Cutting Machine Head Accessories

The Importance of Protecting Lenses for Laser Cutting Machines:

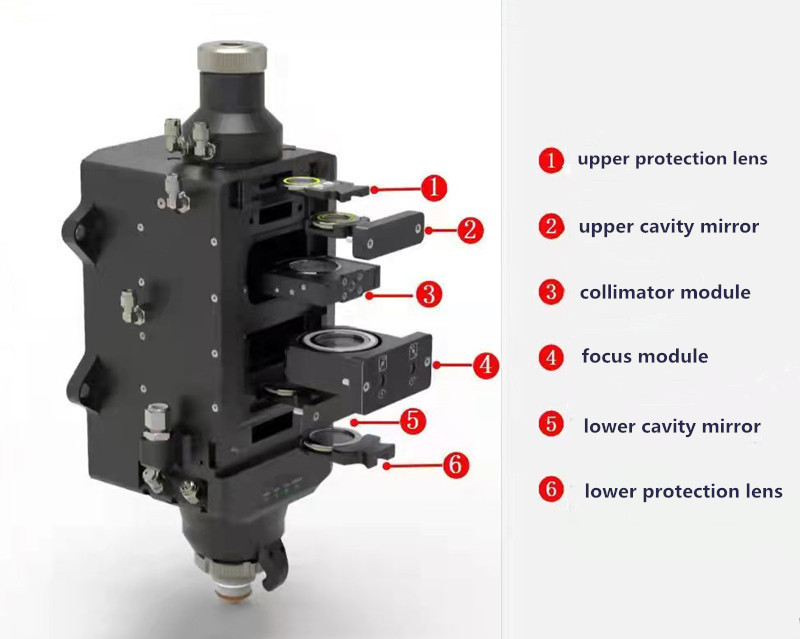

The protective lens of laser cutting machine is also called focusing lens of laser cutting machine. The focusing lens of laser cutting machine is a relatively precise optical element. The protective lens of laser cutting machine is very important for laser cutting machine, and its cleanliness directly affects the quality of laser cutting machine. Machinability and quality. Improper selection of lenses will result in large laser loss, frequent damage to protective lenses, unstable product quality, and serious losses to enterprises. Although the protective lens of the laser cutting machine is a wearing part, in order to improve its utilization rate and reduce the production cost, the protective lens can be cleaned regularly to achieve the purpose of reuse. Therefore, the protective lens of the laser cutting machine should be maintained frequently, and the maintenance precautions of the focusing lens of the laser cutting machine:

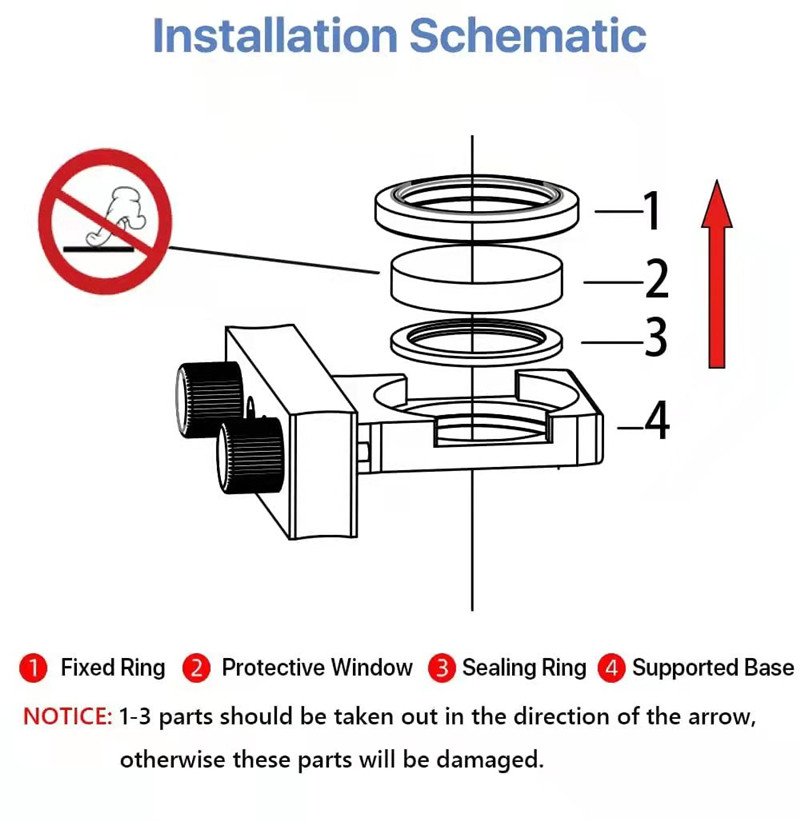

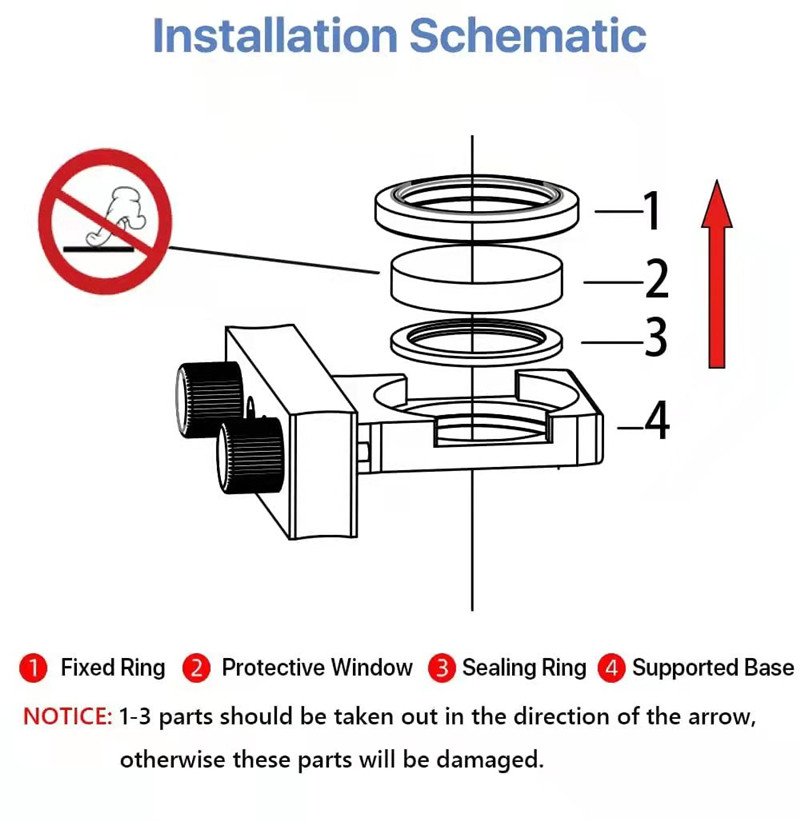

1. The material of the focusing lens is ZnSe (zinc arsenic), which is relatively brittle and is afraid of falling; pay attention when disassembling and assembling: do not use too much force or collide with hard objects. There is an anti-reflection coating on the surface, which is afraid of pollution, moisture, oiliness, and scratches; therefore, it is required to provide dry and degreasing air during work, and do not directly handle the lens of the laser cutting machine focusing lens by hand, because the skin is oily. Permanent damage to the lens surface. Instead, you can operate with gloves and their special kits. For smaller lenses, it is more convenient to use optical tweezers or vacuum tweezers. No matter what method is used to clamp the laser cutter focusing mirror, it should only be clamped along non-optical surfaces, such as the frosted edge of the mirror plaque.

2. In general, the condition of the focusing mirror of the laser cutting machine needs to be checked before use and before and after cleaning. Because of the small size of most contaminants and surface defects, magnification equipment is often required when inspecting lenses. In addition to magnifying the device, sometimes we need to illuminate the optical surface with a brighter light to enhance the specular intensity of surface contamination and defects, which can make them easier to spot.

3. When cleaning a laser cutter focusing mirror, always use clean wipes and optical grade solvents to prevent damage by other contaminants. The wipes must be moistened with a suitable solvent and must not be used dry. In consideration of softness, the available wipes are pure cotton Webril wipes or applicators such as cotton balls, lens tissue, and cotton swabs.

The focusing lens of the laser cutting machine is a consumable item. When the cleanliness cannot be achieved after many times of cleaning, it needs to be replaced to ensure the processing efficiency of the laser cutting machine, so as not to delay the production.

| Protective Lens | D18×T2mm (3KW) | WSX Welding head |

| Protective Lens | D20×T2mm (4KW) | Qilin welding head |

| Protective Lens | D20×T3mm (4KW) |

|

| Protective Lens | D20×T4mm (4KW) | Hanwei Welding head |

| Protective Lens | D21.5×T2mm (15KW) Ordinary | Precitec Procutter1.0 |

| Protective Lens | D21.5×T2mm (15KW) Imported | Precitec Procutter1.0 |

| Protective Lens | D22.35×T4mm (4KW) | Precitec Lightcutter/WSX NC30 |

| Protective Lens | D25.4×T4mm (4KW) | WSX NC12 |

| Protective Lens | D24.9×T1.5mm (4KW) | Raytools BT240S\BM109\BM110\BM111 |

| Protective Lens | D27.9×T4.1mm (4KW) Compatible | Raytools BT240S\BM109\BM110\BM111 |

| Protective Lens | D27.9×T4.1mm (4KW) Raytools Original | Raytools BT240S\BM109\BM110\BM111 |

| Protective Lens | D30×T2mm, D30xT4mm (4KW) | for Welding head |

| Protective Lens | D30×T5mm (4KW) | WSX KC13/KC15/NC30/OSPRI/Precitec Lightcutter |

| Protective Lens | D32×T2mm | WSX NC60 |

| Protective Lens | D34×T3mm(15KW) | DNE |

| Protective Lens | D34×T5mm(6KW) | DNE/Hans/Trumpf |

| Protective Lens | D34×T5mm(15KW)OrdinaryS1 | DNE/Hans/Trumpf |

| Protective Lens | D34×T5mm(15KW)Imported S1 | PORAD Head BTL640/BTL641/BTL831 |

| Protective Lens | D36xT5mm (12KW) | Highyag |

| Protective Lens | D37×T1.6mm(15KW) Ordinary | Raytools BM114/BM115 |

| Protective Lens | D37×T1.6mm(15KW) D37×T1.6mm Raytools Original | Raytools BM114/BM115 |

| Protective Lens | D37×T7mm(6KW) Ordinary | Precitec procutter/Raytools BM114S/BM115/WSX NC60 |

| Protective Lens | D37×T7mm(6KW) Raytools Original | Raytools BM114S/BM115 |

| Protective Lens | D37×T7mm(15KW)Ordinary | Precitec procutter |

| Protective Lens | D37×T7mm(15KW)Japan made | Precitec procutter |

| Protective Lens | D37×T7mm(20KW) | Precitec procutter |

| Protective Lens | D38.1×T1.6mm(6KW) Compatible | Raytools BM114S(Old Vesion) |

| Protective Lens | D38.1×T1.6mm(6KW) Raytools Original | Raytools BM114S(OV) |

| Protective Lens | D40xT5mm (12KW) | DNE CUTTING HEAD |

| Protective Lens | D42xT9mm (12KW) | ec+Ophit head |

| Protective Lens | D50xT2mm (6KW) | WSX/Raytools /Trumpf welding head |

| Protective Lens | D55xT9mm (20KW) | IPG cutting head |

The protective lens of laser cutting machine is also called focusing lens of laser cutting machine. The focusing lens of laser cutting machine is a relatively precise optical element. The protective lens of laser cutting machine is very important for laser cutting machine, and its cleanliness directly affects the quality of laser cutting machine. Machinability and quality. Improper selection of lenses will result in large laser loss, frequent damage to protective lenses, unstable product quality, and serious losses to enterprises. Although the protective lens of the laser cutting machine is a wearing part, in order to improve its utilization rate and reduce the production cost, the protective lens can be cleaned regularly to achieve the purpose of reuse. Therefore, the protective lens of the laser cutting machine should be maintained frequently.

Protect the lens During the installation and cleaning process, any sticky substance, or even oil droplets printed on the nails, will increase the absorption rate of the lens and reduce the service life. Therefore, the cleaning work of the lens cannot be ignored:

Gloves must be worn during installation, and no fingerprints can be left;

Do not let anything scratch the surface of the lens;

When taking the lens, hold the edge of the lens with both fingers and do not touch the film;

Lens cleaning with clean tissue, test paper and optical grade solvent;