TB032 CNC Sheet Metal Folding Machine

3200mm Sheet Metal Folder for Seamless Bends and Creases

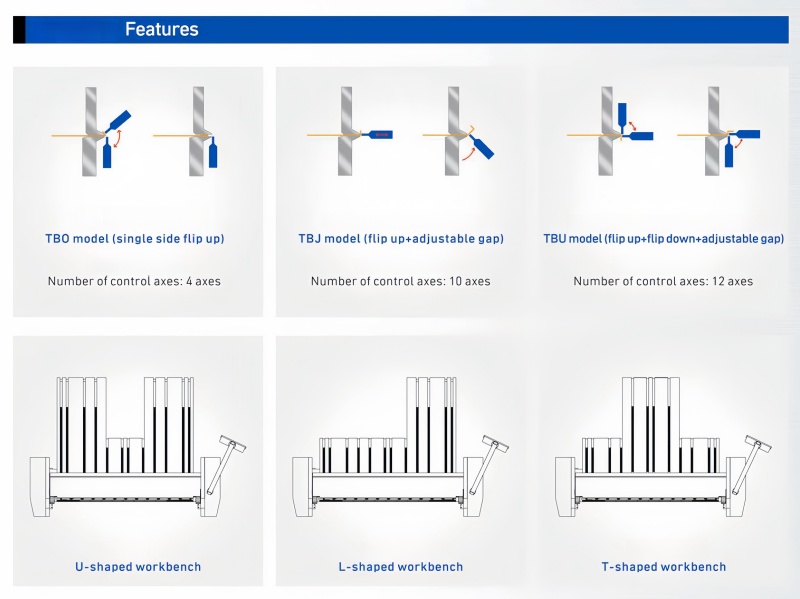

The TB032 CNC Folding Machine is a precision-engineered sheet metal forming solution, designed for high-quality folding applications with a maximum working length of 3200 mm. Belonging to the TBO series (single-side upward folding), the TB032 offers superior bending accuracy, consistent performance, and high productivity. With advanced CNC control and a rigid structural design, it is an ideal choice for workshops and factories producing medium-to-large sheet metal components.

1. CNC-Controlled Precision

The TB032 is equipped with a 4-axis CNC control system, ensuring accurate folding operations across a wide range of applications. Operators can program bending angles, clamping positions, and back gauge settings with ease, achieving repeatable accuracy for both small and large batches.

2. Large Working Capacity

With a maximum bending length of 3200 mm, the TB032 is suitable for processing longer sheet metal panels such as doors, facades, and cabinet bodies. It can handle carbon steel up to 2.0 mm thick and stainless steel up to 1.5 mm, making it versatile for different industries.

Max. Carbon Steel Thickness: 2.0 mm

Max. Stainless Steel Thickness: 1.5 mm

Max. Folding Length: 3200 mm

3. Speed and Efficiency

The TB032 is designed for efficient mass production. With a clamping speed of 200 mm/s and a folding speed of 100°/s, it ensures fast cycle times while maintaining high accuracy.

Clamping Speed: 200 mm/s

Folding Speed: 100°/s

4. Robust Structural Design

The machine is built with a heavy-duty welded frame to minimize vibration and ensure stability during operation. This robust structure guarantees consistent performance, even in demanding production environments.

5. Energy-Efficient Drive

The TB032 uses a 5.5 kW motor, providing powerful performance while keeping energy consumption low. It is suitable for workshops focused on reducing operating costs while maintaining productivity.

Performance Advantages

High Accuracy: CNC-controlled operations ensure precise folding angles and consistent dimensions.

Productivity Boost: Suitable for medium-to-large sheet processing, achieving high throughput.

Flexibility: Capable of handling different metals including carbon steel, stainless steel, and aluminum.

Durability: Heavy-duty structure and CE-certified safety design ensure reliable long-term operation.

Operator-Friendly: Intuitive CNC interface and ergonomic design make operation simple and efficient.

Applications

The TB032 is widely used in industries requiring precise and large-format sheet metal folding. Typical applications include:

Construction & Architecture: Facade panels, roofing sheets, door and window frames.

HVAC Systems: Air ducts, ventilation panels, air-conditioning casings.

Electrical Enclosures: Control cabinet panels, switchgear housings.

Furniture & Kitchen Equipment: Stainless steel tables, cabinets, shelves.

Elevators & Transportation: Elevator panels, decorative trims, vehicle interior sheet parts.

Appliances & Consumer Goods: Refrigerator panels, washing machine covers, stainless steel sinks.

Technical Specifications (TB032)

| Item | Unit | TB032 |

| Max. Sheet Thickness (Carbon Steel) | mm | 2.0 |

| Max. Sheet Thickness (Stainless Steel) | mm | 1.5 |

| Bending Angle Range | ° | 45–180 |

| Max. Bending Length | mm | 3200 |

| Back Gauge Length | mm | 3200 |

| Open Height | mm | 380 |

| Tool Height | mm | 125 |

| Control Axes | — | 4 |

| Clamping Speed | mm/s | 200 |

| Folding Speed | °/s | 100 |

| Motor Power | kW | 5.5 |

| Machine Dimensions (L × W × H) | mm | 3800 × 4450 × 1900 |

| Machine Weight | Kg | 4500 |

Conclusion

CNC Control System:

CPU: Intel Core i5.

Memory: 8GB.

Hard disk: 64GB SSD.

Key features: online and offline programming, backup, real-time status monitoring, Windows OS, and support for scanning codes.

Axis Configuration:

TBJ model: 10 axes.

A-axis travel: 0-88mm.

B-axis travel: 0-120mm.

Technical Parameters:

Includes various models such as TB025, TB032, TB041, and TBU32 with information like bending force, bending length, and axis speeds.

Technical Parameters

| Item | Unit | TB025 | TB032 | TB041 | TBU25 | TBU32 | TBU41 |

| Processing thickness | mm | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 |

| Processing thickness (stainless steel) | mm | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Bending length | mm | 2500 | 3200 | 4100 | 2500 | 3200 | 4100 |

| Bending angle | degrees | 45...180 | 45...180 | 45...180 | 45...180 | 45...180 | 45...180 |

| Speed | mm/s | 30 | 30 | 30 | 30 | 30 | 30 |

| X-axis travel | mm | 2500 | 3200 | 4100 | 2500 | 3200 | 4100 |

| Y-axis travel | mm | 100 | 100 | 100 | 100 | 100 | 100 |

| Z-axis travel | mm | 2500 | 3200 | 4100 | 2500 | 3200 | 4100 |

| Main motor power | kW | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 |

| Dimensions (L x W x H) | mm | 3100x1800x3100 | 3700x1800x3100 | 4500x1800x3100 | 3100x1800x3100 | 3700x1800x3100 | 4500x1800x3100 |

| Weight | kg | 3500 | 4500 | 7500 | 4000 | 6000 | 8000 |

This table shows key specifications such as processing thickness, bending length, bending angle, speed, axis travel ranges, motor power, dimensions, and weight for different CNC folding machine models.