CNC sheet metal folding machine is a high-precision automated tool designed for bending and shaping sheet metal. It operates using a computer numerical control (CNC) system to manage the machine's movements with high accuracy and consistency. These machines are widely used in industries such as automotive, aerospace, construction, and electronics to create complex metal components with precise bends and folds.

Key Features of a CNC Sheet Metal Folding Machine:

CNC Control System:

The machine is controlled by a computer, which allows for highly accurate and repeatable operations. The CNC system can store multiple programs and provides a graphical interface to facilitate programming and real-time adjustments.

Features like automatic upgrades, data backup, real-time status monitoring, and remote access increase efficiency.

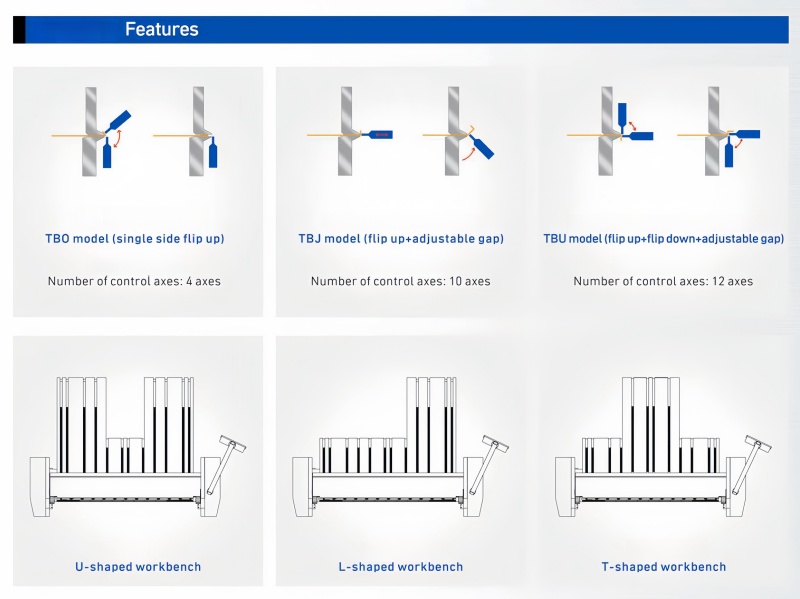

Axes Movement:

The machine typically has multiple axes (X, Y, Z, and others) that control the movements of the folding tools. The number of axes can range from simple configurations (3-axes) to advanced models (up to 10 axes), allowing for complex part geometries.

These axes are responsible for positioning the sheet metal, adjusting the bending tools, and executing the folding process.

Bending Length & Thickness:

Bending Angle Control:

Power and Speed:

Automation and Safety:

CNC folding machines often feature automated safety systems like light curtains and cup feeding mechanisms to enhance operator safety and prevent accidents.

These machines can work autonomously once programmed, improving productivity and reducing manual intervention.

Applications:

The CNC sheet metal folding machines are used in the production of parts for automobiles, aerospace components, metal enclosures, construction materials, and electronic housings.

Benefits of Using a CNC Sheet Metal Folding Machine:

Precision: The CNC system ensures highly accurate bends with minimal tolerance errors.

Efficiency: The ability to automate the bending process increases production speed and consistency.

Flexibility: Multi-axis control allows for complex bending operations, including curved or non-linear folds.

Cost-effective: Reduces waste and material costs due to precision control.

Ease of Use: CNC interfaces are designed for ease of programming and operation, reducing setup times.

CNC Control System:

CPU: Intel Core i5.

Memory: 8GB.

Hard disk: 64GB SSD.

Key features: online and offline programming, backup, real-time status monitoring, Windows OS, and support for scanning codes.

Axis Configuration:

TBJ model: 10 axes.

A-axis travel: 0-88mm.

B-axis travel: 0-120mm.

Technical Parameters:

Includes various models such as TB025, TB032, TB041, and TBU32 with information like bending force, bending length, and axis speeds.

Technical Parameters

| Item | Unit | TB025 | TB032 | TB041 | TBU25 | TBU32 | TBU41 |

| Processing thickness | mm | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 |

| Processing thickness (stainless steel) | mm | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Bending length | mm | 2500 | 3200 | 4100 | 2500 | 3200 | 4100 |

| Bending angle | degrees | 45...180 | 45...180 | 45...180 | 45...180 | 45...180 | 45...180 |

| Speed | mm/s | 30 | 30 | 30 | 30 | 30 | 30 |

| X-axis travel | mm | 2500 | 3200 | 4100 | 2500 | 3200 | 4100 |

| Y-axis travel | mm | 100 | 100 | 100 | 100 | 100 | 100 |

| Z-axis travel | mm | 2500 | 3200 | 4100 | 2500 | 3200 | 4100 |

| Main motor power | kW | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 |

| Dimensions (L x W x H) | mm | 3100x1800x3100 | 3700x1800x3100 | 4500x1800x3100 | 3100x1800x3100 | 3700x1800x3100 | 4500x1800x3100 |

| Weight | kg | 3500 | 4500 | 7500 | 4000 | 6000 | 8000 |

This table shows key specifications such as processing thickness, bending length, bending angle, speed, axis travel ranges, motor power, dimensions, and weight for different CNC folding machine models.