400mm wet grinding machine with two abrasive belts and one polishing wheel is typically designed for precision grinding, deburring, edge rounding, and surface finishing of metal parts. This configuration provides versatility for material removal and final polishing, making it suitable for various metalworking industries.

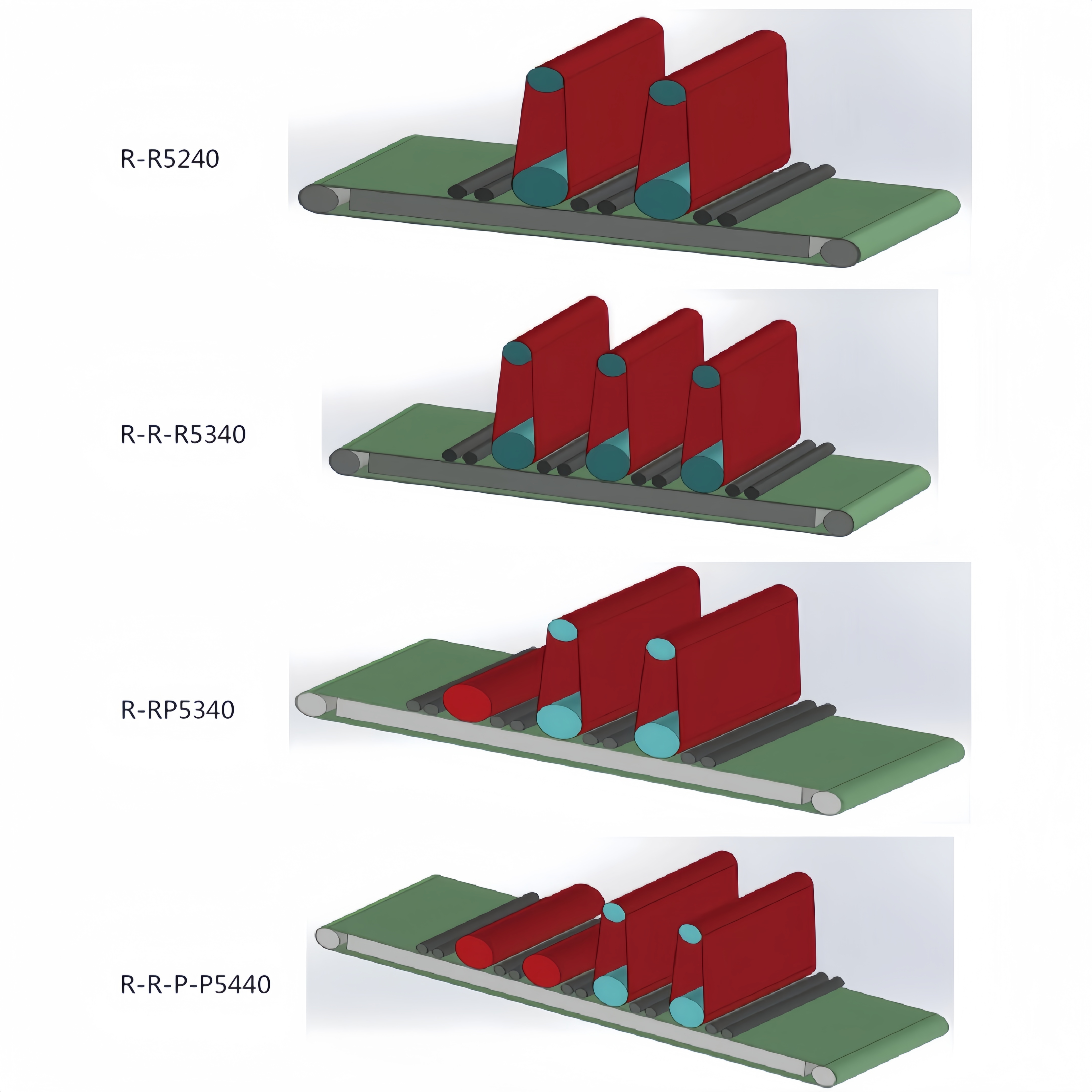

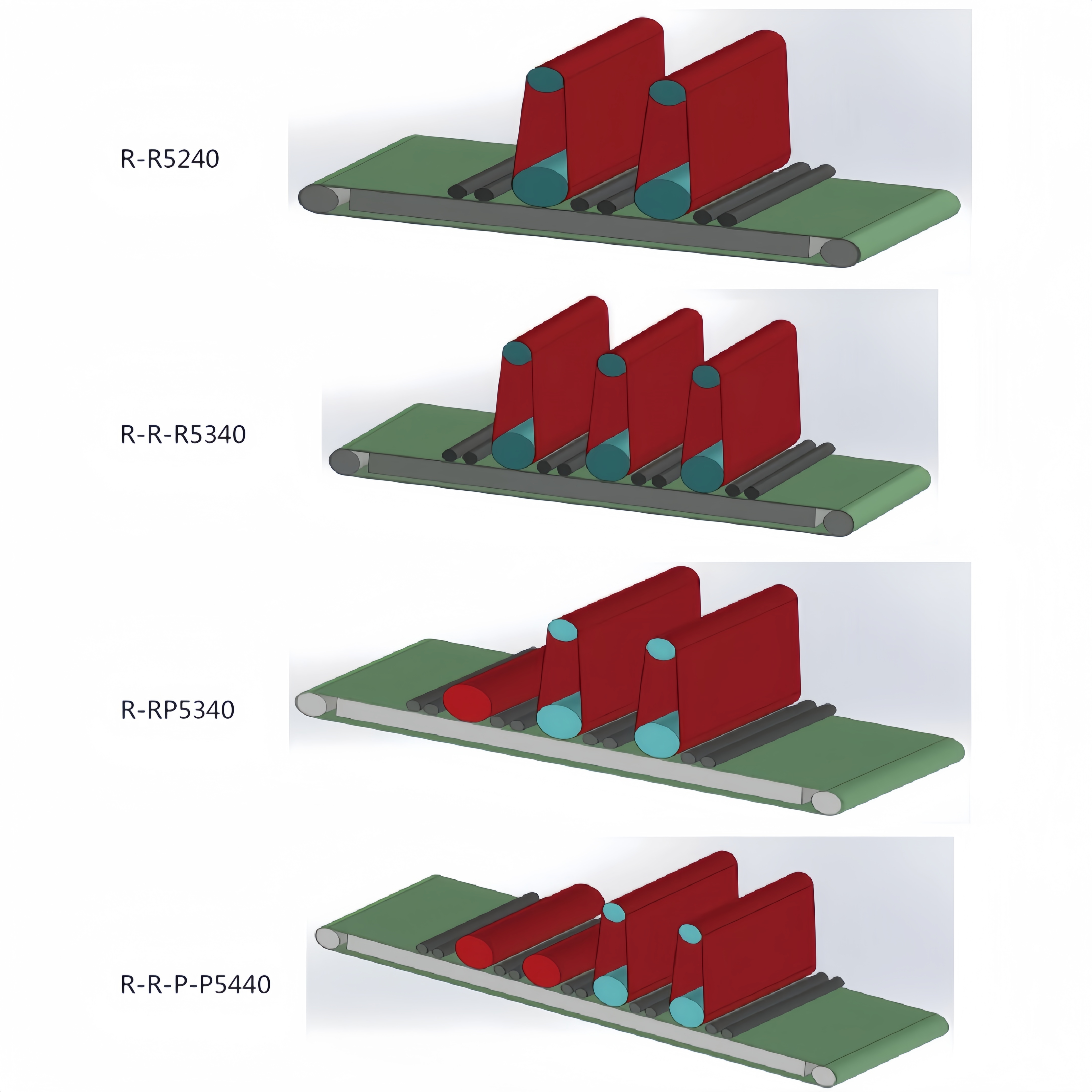

400mm Wet Grinding Machine Series with two belts and a polishing wheel, based on the different models:

| Parameter | Unit | R5240 | RR5240 | RP5240 | RRR5340 | RRP5340 | RRRP5440 |

| Max Working Width | mm | 400 | 400 | 400 | 400 | 400 | 400 |

| Max Working Height | mm | 60 | 60 | 60 | 60 | 60 | 60 |

| Min Working Length | mm | 150 | 150 | 150 | 150 | 150 | 150 |

| First Belt Power | kW | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 |

| Second Belt Power | kW | - | 5.5 | - | 5.5 | 5.5 | 5.5 |

| Third Belt Power | kW | - | - | - | 5.5 | - | 5.5 |

| Polishing Wheel Power | kW | - | - | - | - | 5.5 | 5.5 |

| Rotating Motor Power | kW | - | - | - | - | - | - |

| Feed Power | kW | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Lifting Power | kW | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 |

| Oscillating Motor Power | kW | - | - | 1.5 | - | 1.5 | 1.5 |

| Vacuum Motor Power | kW | - | - | - | - | - | - |

| Machine Dimensions | m | 1.81.51.8 | 2.11.51.8 | 2.11.51.8 | 2.41.51.8 | 2.41.51.8 | 2.71.51.8 |

| Machine Weight | kg | 1000 | 1200 | 1200 | 1500 | 1500 | 1800 |

| Belt Size | mm | 1520*400 | 1520*400 | 1520*400 | 1520*400 | 1520*400 | 1520*400 |

Key Points:

RR5240 and RRP5340 models include a second abrasive belt and polishing wheel, making them suitable for multi-step grinding and finishing processes.

RRR5340 and RRRP5440 models have a third abrasive belt, which allows for more extensive material removal or finer sanding.

The polishing wheel in RRP5340 and RRRP5440 enables a smoother, polished finish after the sanding stages.

Key Specifications for a 400mm Two Belt, One Polishing Wheel Machine:

Max Working Width: 400mm

Abrasive Belt System:

First Belt Power: Handles rough sanding and initial material removal.

Second Belt Power: Used for finer sanding or intermediate finishing.

Belt sizes vary, typically around 1520mm x 400mm.

Polishing Wheel Power:

The polishing wheel is used for achieving a smooth, polished finish after the sanding process.

Power ranges typically around 5.5 kW for efficient polishing.

Wet Operation: The machine uses water or coolant to reduce heat and friction, ensuring a better surface finish and prolonging tool life.

Feeding Power: Around 1.5-3 kW, responsible for moving the workpiece through the machine.

Adjustable Pressure: Ability to control the pressure applied by the belts and polishing wheel to achieve the desired surface quality.

Vacuum and Filtration: Built-in water filtration to remove debris and recycle the coolant for a cleaner operation.

Advantages:

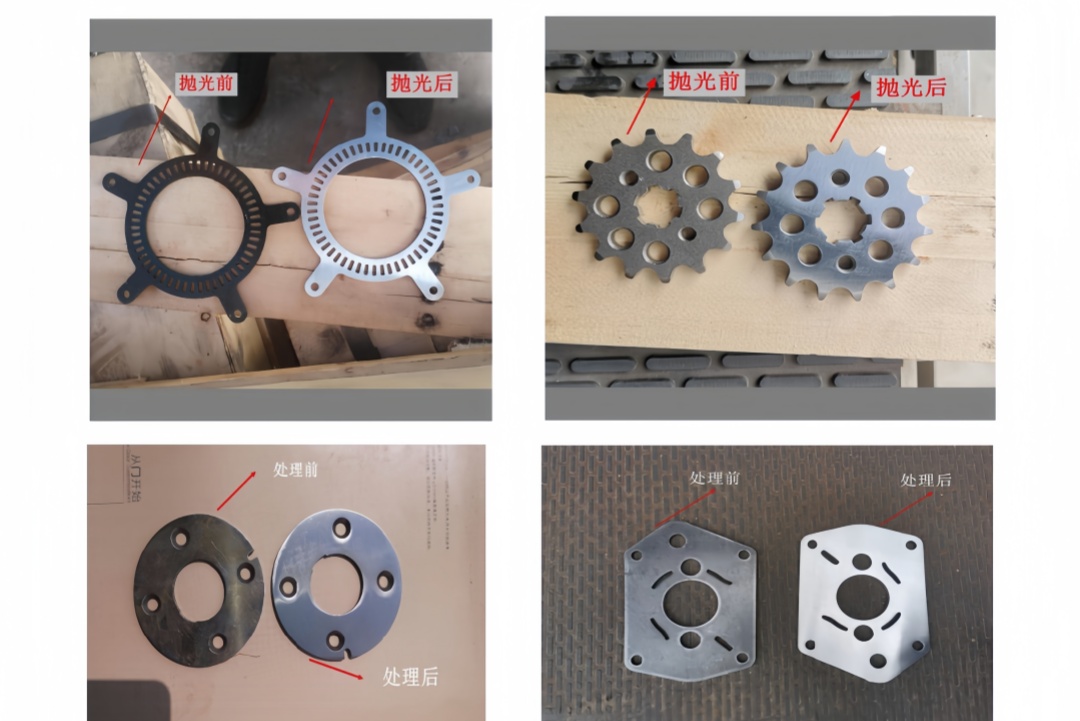

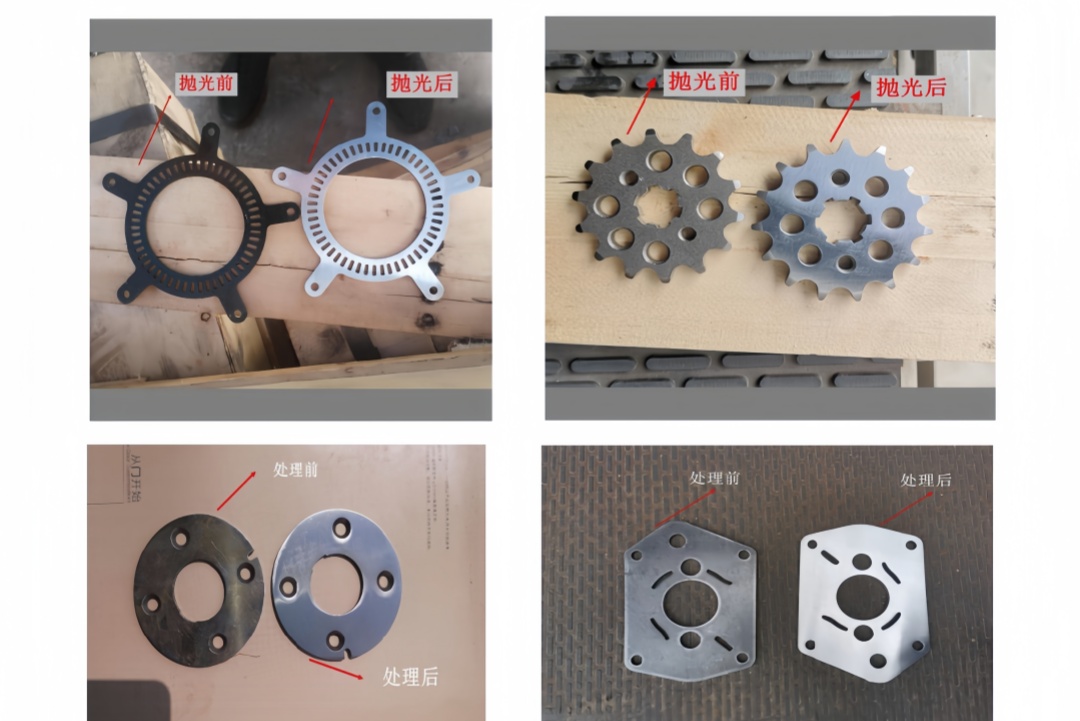

High-Precision Finishing: Two belts allow for multi-stage grinding, followed by polishing for a refined finish.

Wet Operation: Prevents overheating, improves belt life, and delivers a higher-quality surface finish.

Compact and Efficient: With a 400mm working width, the machine is suitable for medium-sized parts and components.

Versatile Applications: Suitable for deburring, edge rounding, surface grinding, and final polishing of metal parts (stainless steel, carbon steel, aluminum, etc.).

This type of machine is ideal for industries like metal fabrication, automotive, aerospace, and sheet metal processing, where both heavy material removal and precision surface finishing are required.