400mm wet wide belt sander with three sanding heads and one brush head is designed for high-precision grinding, sanding, and finishing. This type of machine provides multiple stages of sanding, followed by a final brushing for edge rounding, deburring, or polishing. The combination of wet operation and a brush head makes it ideal for applications requiring a high-quality surface finish.

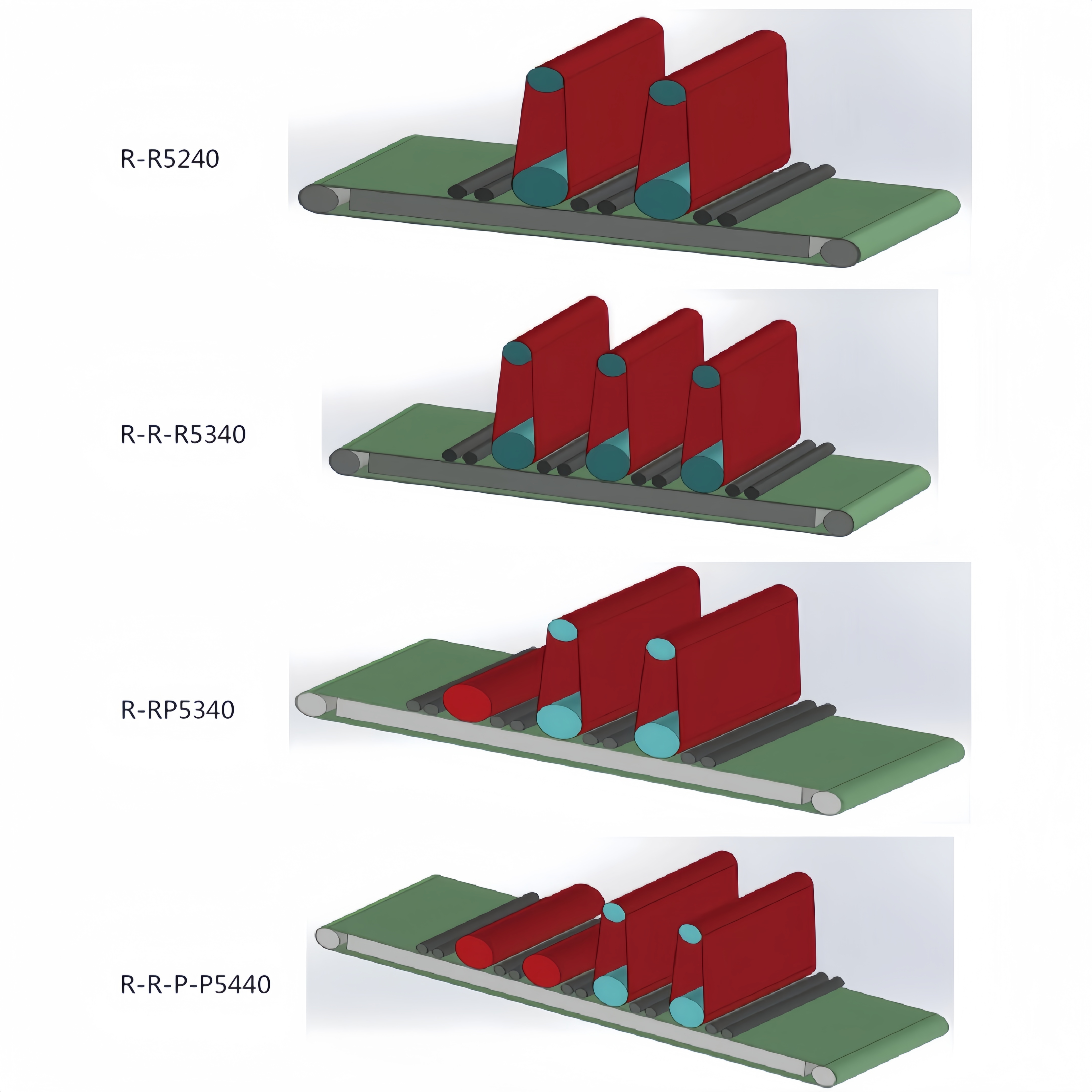

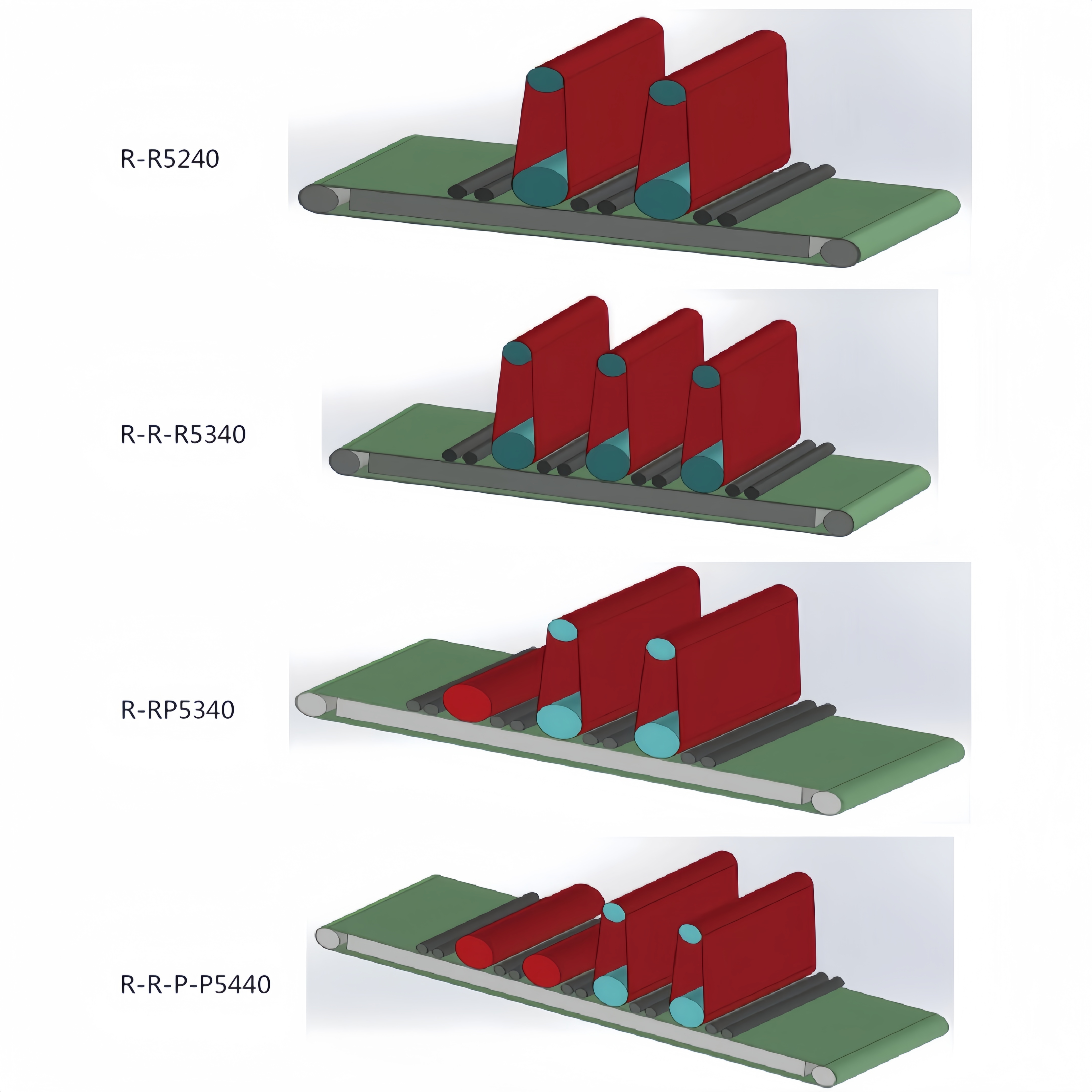

400mm Wet Grinding Machine Series with two belts and a polishing wheel, based on the different models:

| Parameter | Unit | R5240 | RR5240 | RP5240 | RRR5340 | RRP5340 | RRRP5440 |

| Max Working Width | mm | 400 | 400 | 400 | 400 | 400 | 400 |

| Max Working Height | mm | 60 | 60 | 60 | 60 | 60 | 60 |

| Min Working Length | mm | 150 | 150 | 150 | 150 | 150 | 150 |

| First Belt Power | kW | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 |

| Second Belt Power | kW | - | 5.5 | - | 5.5 | 5.5 | 5.5 |

| Third Belt Power | kW | - | - | - | 5.5 | - | 5.5 |

| Polishing Wheel Power | kW | - | - | - | - | 5.5 | 5.5 |

| Rotating Motor Power | kW | - | - | - | - | - | - |

| Feed Power | kW | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Lifting Power | kW | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 |

| Oscillating Motor Power | kW | - | - | 1.5 | - | 1.5 | 1.5 |

| Vacuum Motor Power | kW | - | - | - | - | - | - |

| Machine Dimensions | m | 1.81.51.8 | 2.11.51.8 | 2.11.51.8 | 2.41.51.8 | 2.41.51.8 | 2.71.51.8 |

| Machine Weight | kg | 1000 | 1200 | 1200 | 1500 | 1500 | 1800 |

| Belt Size | mm | 1520*400 | 1520*400 | 1520*400 | 1520*400 | 1520*400 | 1520*400 |

Key Points:

RR5240 and RRP5340 models include a second abrasive belt and polishing wheel, making them suitable for multi-step grinding and finishing processes.

RRR5340 and RRRP5440 models have a third abrasive belt, which allows for more extensive material removal or finer sanding.

The polishing wheel in RRP5340 and RRRP5440 enables a smoother, polished finish after the sanding stages.

Key Features:

Three Sanding Heads:

First head for coarse grinding and material removal.

Second head for finer sanding and surface refinement.

Third head for precision finishing, leaving the surface smooth and ready for the next operation.

Brush Head:

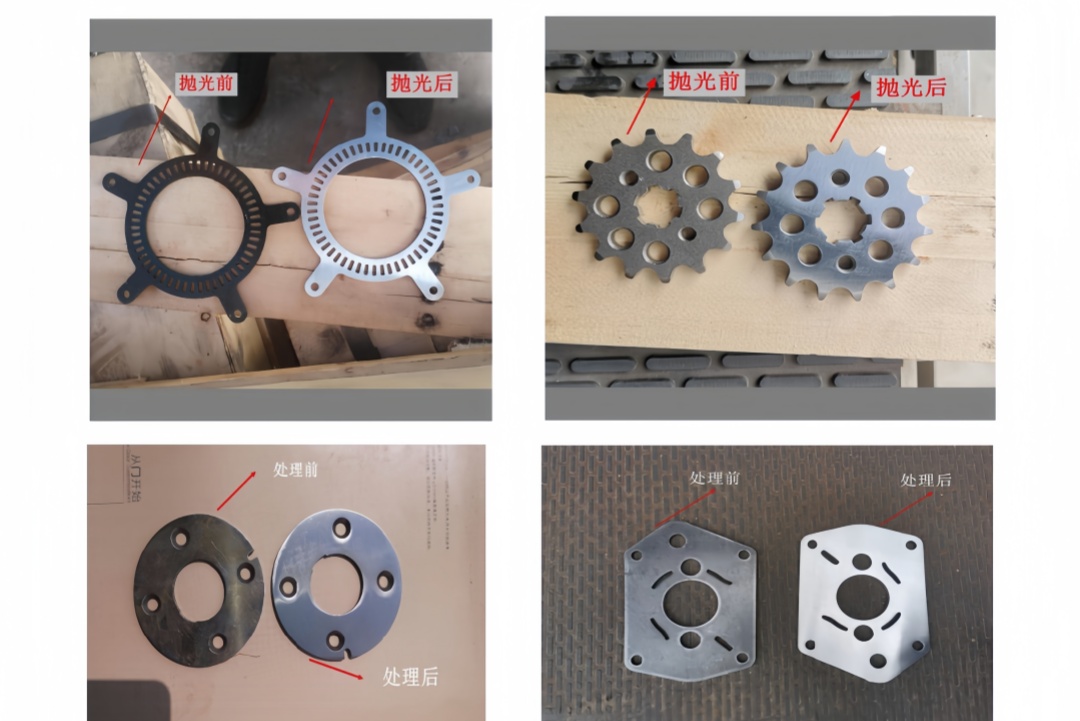

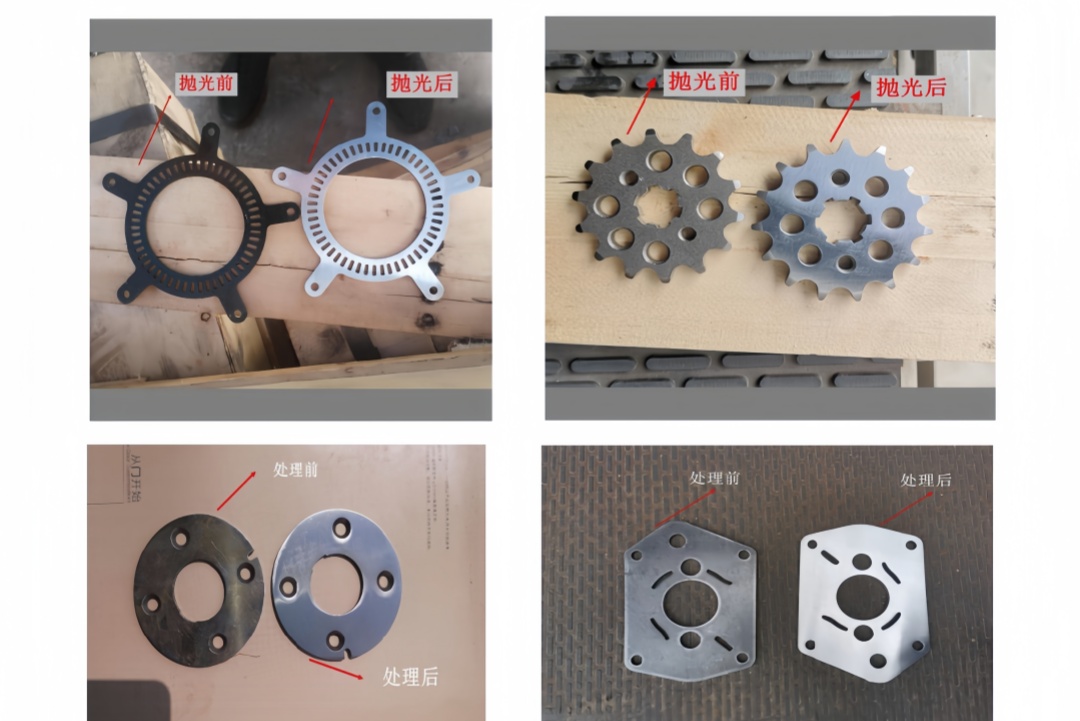

The brush head is typically used for edge rounding, deburring, or polishing, ensuring a uniform finish across all edges and removing any sharp burrs left after the sanding process.

It can also remove oxides from metal surfaces, making it suitable for pre-painting or other finishing treatments.

Wet Operation:

Water or coolant is used to reduce heat and friction during sanding, which improves surface quality and prolongs the life of the sanding belts and brushes.

Wet operation also helps control dust and ensures a cleaner working environment.

Adjustable Pressure:

Versatility:

This machine is suitable for various materials like stainless steel, carbon steel, aluminum, and other non-ferrous metals.

It can handle different processes, including deburring, edge rounding, oxide removal, and surface finishing.

Applications:

Ideal for industries such as metal fabrication, automotive, aerospace, and any application requiring high-quality surface preparation and finishing.