400mm Wet Wide Belt Sander Sanding Machine for Deburring and Edge Rounding of Laser-Cut and Stamped Sheet Metal (Model: RRR5340)

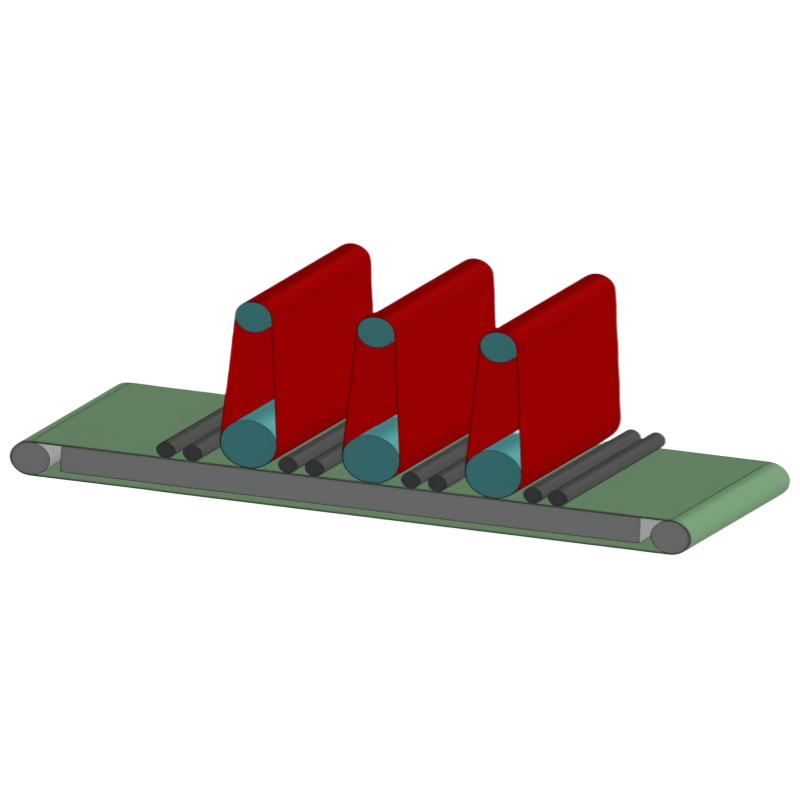

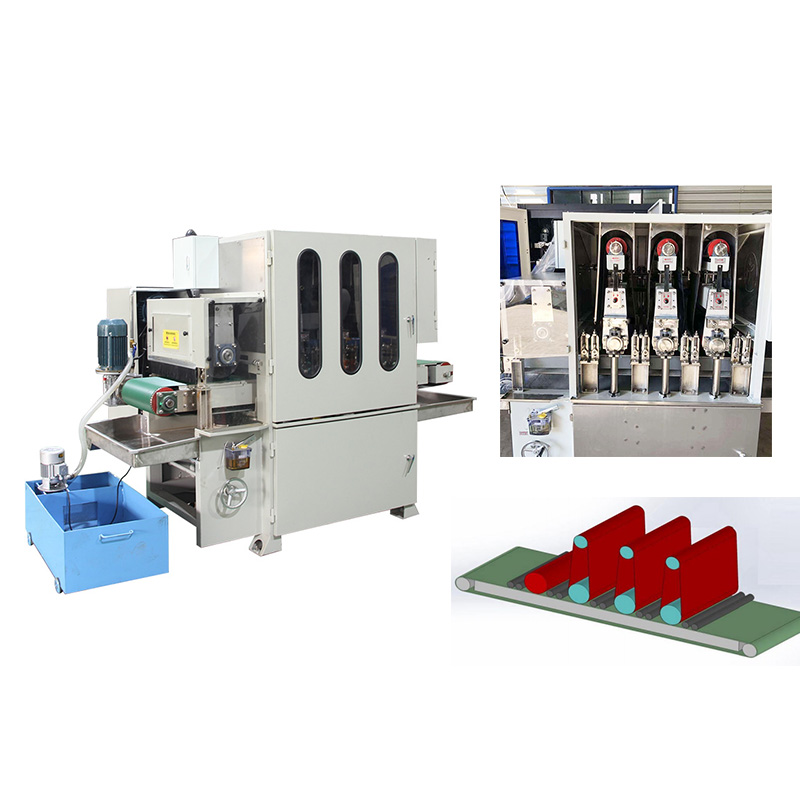

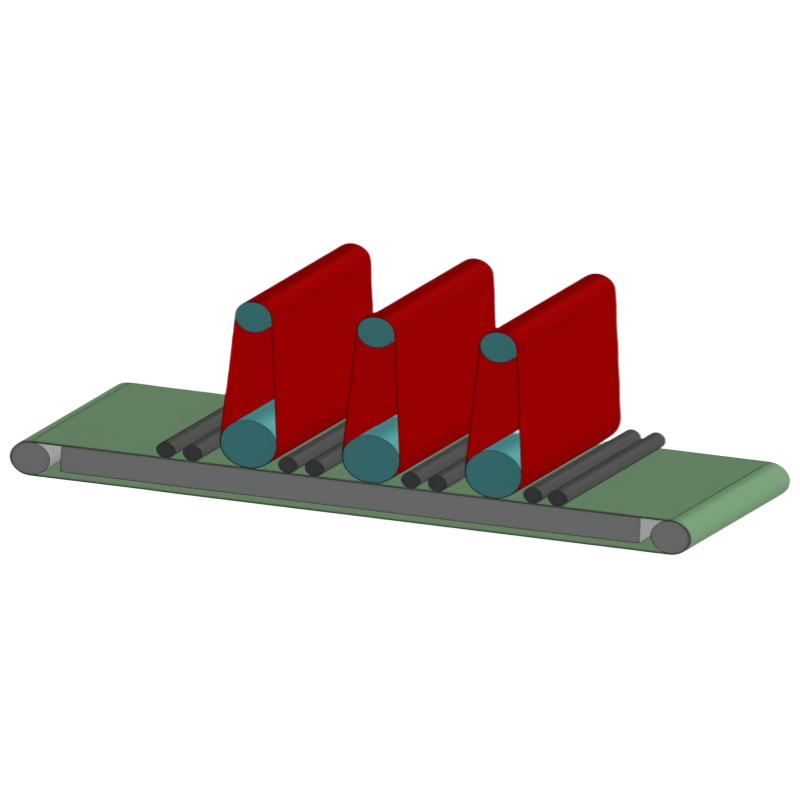

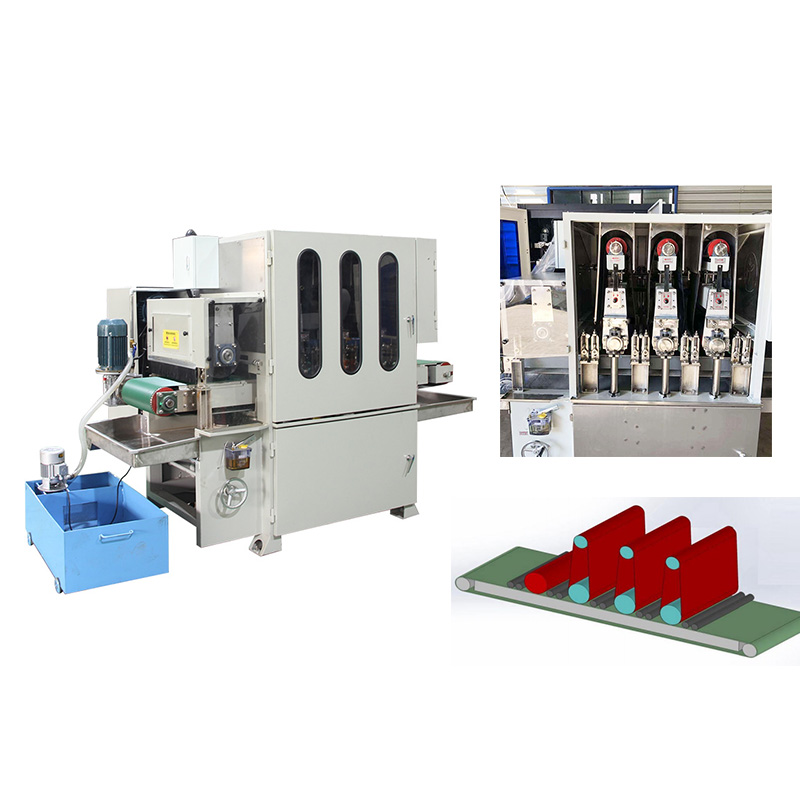

The RRR5340 400mm Wet Wide Belt Sander is an industrial-grade deburring and edge rounding machine designed for laser-cut and stamped sheet metal parts. Equipped with three sanding stations, each with an independent abrasive belt, this machine delivers progressive sanding, deburring, and finishing in a single pass.

Using a wet grinding process, the RRR5340 effectively removes burrs, smooths sharp edges, eliminates oxidation layers, and enhances surface uniformity. It is ideal for stainless steel, aluminum, carbon steel, and other metal materials, ensuring a high-quality surface finish required in automotive, aerospace, electronics, and general metal fabrication industries.

With a maximum working width of 400mm, the machine is perfect for medium-sized sheet metal parts, offering high efficiency, consistent results, and improved workplace safety through dust suppression and cooling technology.

Key Features & Functions

1. Three-Station Sanding System for Precision Deburring

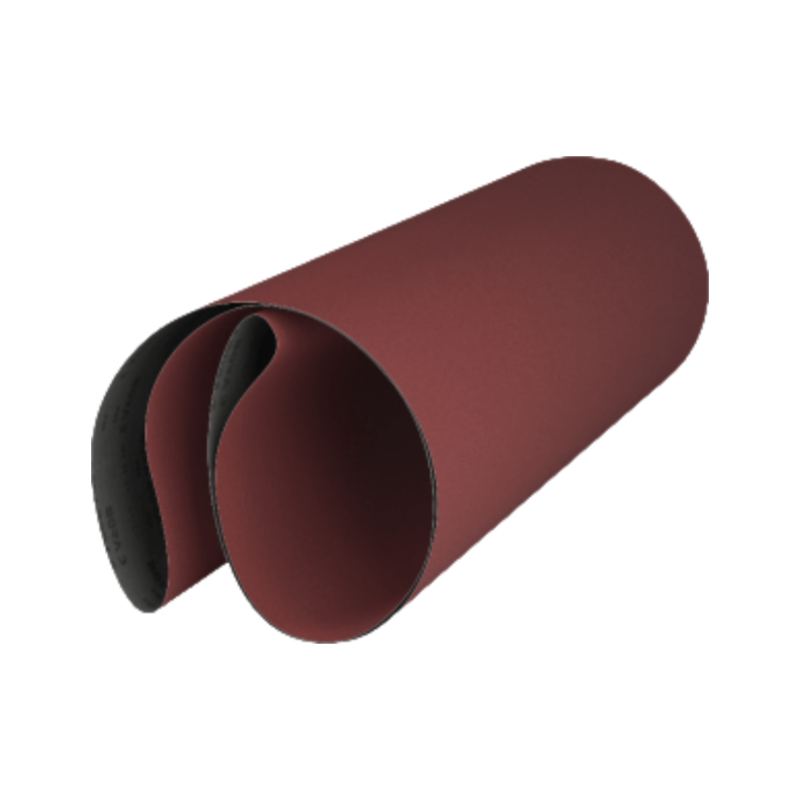

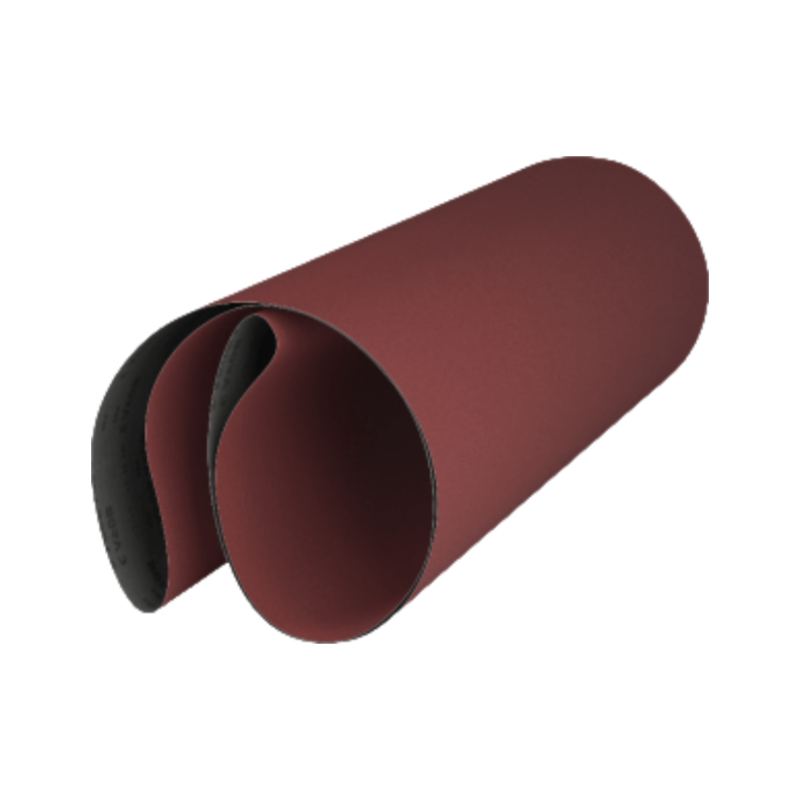

The machine features three independent sanding stations, each equipped with a 1520×400mm abrasive belt.

First belt (7.5kW) – Aggressive deburring to remove large burrs and sharp edges.

Second belt (5.5kW) – Fine deburring and surface leveling to prepare for edge rounding.

Third belt (5.5kW) – Edge rounding and finishing, ensuring smooth and safe handling.

This multi-stage processing results in consistent and high-quality finishes across all workpieces.

2. Advanced Wet Sanding & Cooling System

Water-based grinding technology cools the workpiece, preventing heat deformation and discoloration.

The wet system also minimizes airborne dust, improving operator safety and workshop cleanliness.

An integrated coolant circulation system increases abrasive belt lifespan and maintains optimal grinding performance.

3. Wide Compatibility for Various Metal Parts

Handles workpieces up to 400mm wide and 60mm thick, suitable for laser-cut, stamped, and punched metal sheets.

Minimum workpiece length of 150mm, making it suitable for small to medium-sized components.

Compatible with stainless steel, aluminum, carbon steel, and other metal materials.

4. High-Efficiency Material Feeding & Adjustable Controls

Precision conveyor feed system ensures smooth material transport and consistent surface finishing.

Adjustable feed speed allows operators to customize processing based on material type and thickness.

User-friendly control panel for easy adjustment of sanding pressure, speed, and belt tension.

5. Heavy-Duty Structure for Industrial Applications

Built with a rigid, industrial-grade frame for stability and durability in high-production environments.

Stainless steel construction for corrosion resistance in wet sanding applications.

Compact design (2.4m × 1.5m × 1.8m) allows for easy integration into existing production lines.

6. Energy-Efficient & Low Maintenance

Independent motor drives for each sanding belt optimize energy consumption.

Quick-change belt system reduces downtime, improving production efficiency.

Automatic water filtration and drainage system for minimal maintenance.

Technical Specifications

| Parameter | Unit | RRR5340 Model |

| Max. Working Width | mm | 400 |

| Max. Working Height | mm | 60 |

| Min. Working Length | mm | 150 |

| First Sanding Belt Power | kW | 7.5 |

| Second Sanding Belt Power | kW | 5.5 |

| Third Sanding Belt Power | kW | 5.5 |

| Polishing Wheel Power | kW | / |

| Rotation Motor Power | kW | / |

| Feeding Motor Power | kW | 1.5 |

| Lifting Motor Power | kW | 0.37 |

| Oscillation Motor Power | kW | / |

| Vacuum Motor Power | kW | / |

| Machine Dimensions (L×W×H) | m | 2.4 × 1.5 × 1.8 |

| Machine Weight | kg | 1500 |

| Sanding Belt Size | mm | 1520 × 400 |

Typical Applications

1. Laser-Cut Metal Sheet Processing

Removes heat-affected zones (HAZ) and sharp burrs from laser-cut parts.

Ensures smooth and safe edges for handling and further processing.

Prepares surfaces for coating, welding, and anodizing.

2. Deburring & Edge Rounding for Stamped Parts

Smooths rough edges and burrs from stamped, punched, and sheared components.

Ensures consistent edge rounding, improving workpiece safety and handling.

3. Oxide Removal & Surface Finishing

Eliminates oxidation layers from plasma-cut and flame-cut metal parts.

Achieves uniform surface roughness, preparing metal for painting, powder coating, or electroplating.

4. Brushed Finishing for Stainless Steel & Aluminum

Creates a consistent brushed or satin finish on decorative metal parts.

Enhances surface appearance and durability for automotive, kitchenware, and architectural components.

Conclusion

The RRR5340 400mm Wet Wide Belt Sander is a high-performance and versatile machine designed for precision deburring, edge rounding, and surface finishing of laser-cut and stamped sheet metal. Its three-station sanding system, wet grinding technology, and high-precision material handling make it an essential tool for improving product quality, reducing labor costs, and optimizing production efficiency.

By integrating the RRR5340 model into your manufacturing process, you can achieve:

✅ Superior surface finishes

✅ Enhanced product consistency

✅ Safer handling with rounded edges

✅ Increased productivity with automated processing

This machine is ideal for industries requiring high-precision metal surface treatment, such as automotive, aerospace, electronics, kitchenware, and industrial metal fabrication.