400mm Wet Wide Belt Sander Sanding Machine for Laser-Cut and Stamped Sheet Metal (Model: RR5240)

The RR5240 400mm Wet Wide Belt Sander is an industrial-grade metal surface treatment machine specifically designed for laser-cut and stamped sheet metal parts. This machine efficiently performs deburring, deslagging, oxide removal, surface sanding, and finishing, ensuring high precision and uniformity across various metal materials.

With a maximum working width of 400mm, it is ideal for processing medium-sized metal sheets and components, providing a consistent surface finish required in automotive, aerospace, electronics, and general metal fabrication industries. The wet grinding system significantly reduces dust and heat, preventing material deformation and enhancing workpiece quality.

Key Features & Functions

1. High-Efficiency Wet Sanding & Deburring

Utilizes wet grinding technology to minimize heat buildup, ensuring no material warping or discoloration.

Reduces airborne dust and improves workshop safety with an integrated coolant circulation system.

Effectively removes sharp burrs, oxidation layers, and cutting slag from laser-cut and stamped parts.

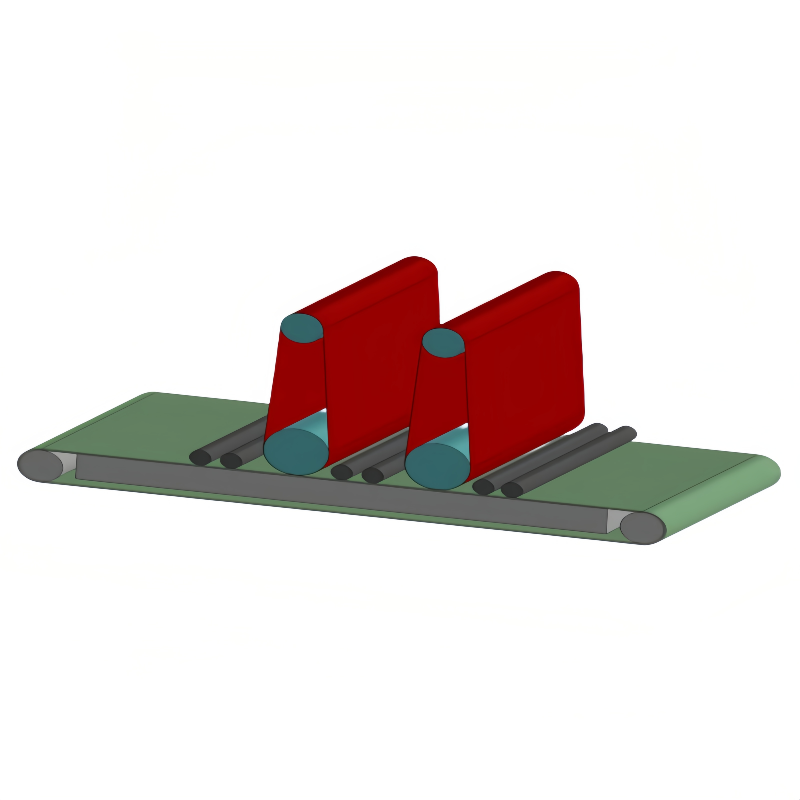

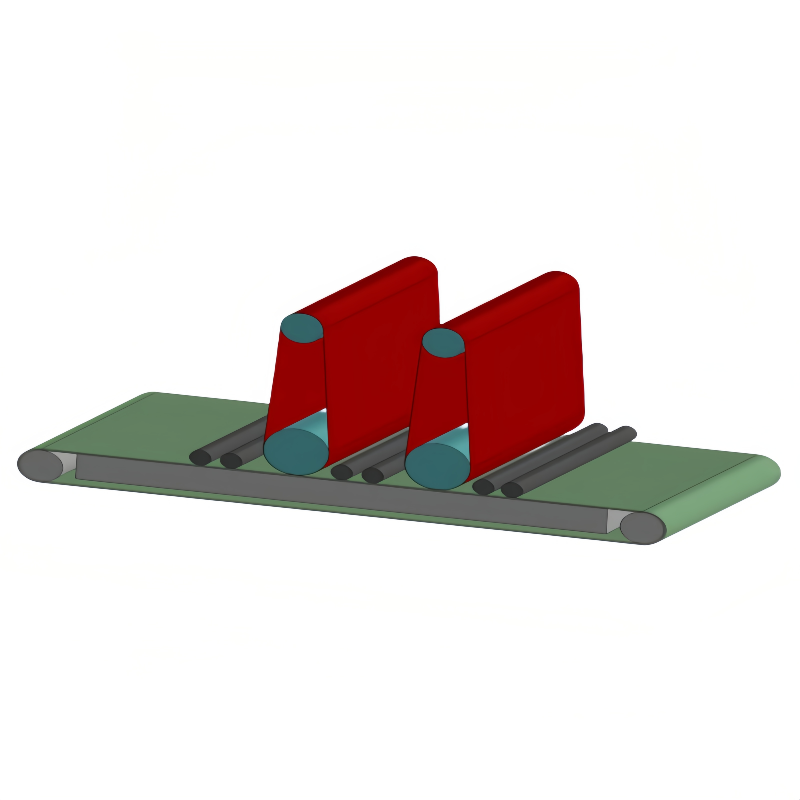

2. Wide Belt Sanding System (400mm Working Width)

Equipped with two high-power sanding belts for progressive grinding and finishing.

Allows for customizable surface finishes, from coarse deburring to fine polishing.

Quick belt replacement system for minimal downtime and efficient production.

3. Advanced Material Handling

Supports workpieces up to 60mm thick, accommodating a wide range of metal components.

Minimum part length of 150mm, making it suitable for small to medium-sized sheet metal parts.

Precision conveyor feed system ensures smooth material transport and consistent processing results.

4. Robust & Durable Machine Structure

Heavy-duty industrial design for long-term durability and stable operation.

Constructed from corrosion-resistant stainless steel, ideal for wet processing environments.

Compact footprint (2.1m × 1.5m × 1.8m) allows for easy integration into existing production lines.

5. Energy-Efficient & User-Friendly Operation

User-friendly control panel for adjusting processing speeds, pressure, and settings.

Variable feed speed control optimizes processing for different materials and surface requirements.

Low power consumption relative to output efficiency, reducing overall operational costs.

6. Versatile Applications

Deburring and edge rounding for laser-cut and stamped sheet metal.

Oxide layer removal to enhance coating adhesion.

Fine surface finishing for decorative or functional applications.

Preparation of metal parts for welding, painting, and powder coating.

Technical Specifications

| Parameter | Unit | RR5240 Model |

| Max. Working Width | mm | 400 |

| Max. Working Height | mm | 60 |

| Min. Working Length | mm | 150 |

| First Sanding Belt Power | kW | 7.5 |

| Second Sanding Belt Power | kW | 5.5 |

| Third Sanding Belt Power | kW | / |

| Polishing Wheel Power | kW | / |

| Rotation Motor Power | kW | / |

| Feeding Motor Power | kW | 1.5 |

| Lifting Motor Power | kW | 0.37 |

| Oscillation Motor Power | kW | / |

| Vacuum Motor Power | kW | / |

| Machine Dimensions (L×W×H) | m | 2.1 × 1.5 × 1.8 |

| Machine Weight | kg | 1200 |

| Sanding Belt Size | mm | 1520 × 400 |

Typical Applications

Laser-Cut Sheet Metal Processing

Removes heat-affected zones (HAZ) and sharp burrs from laser-cut edges.

Prepares surfaces for coating, welding, and further finishing.

Stamped & Sheared Metal Parts

Deburring & Edge Rounding

Surface Preparation for Painting & Coating