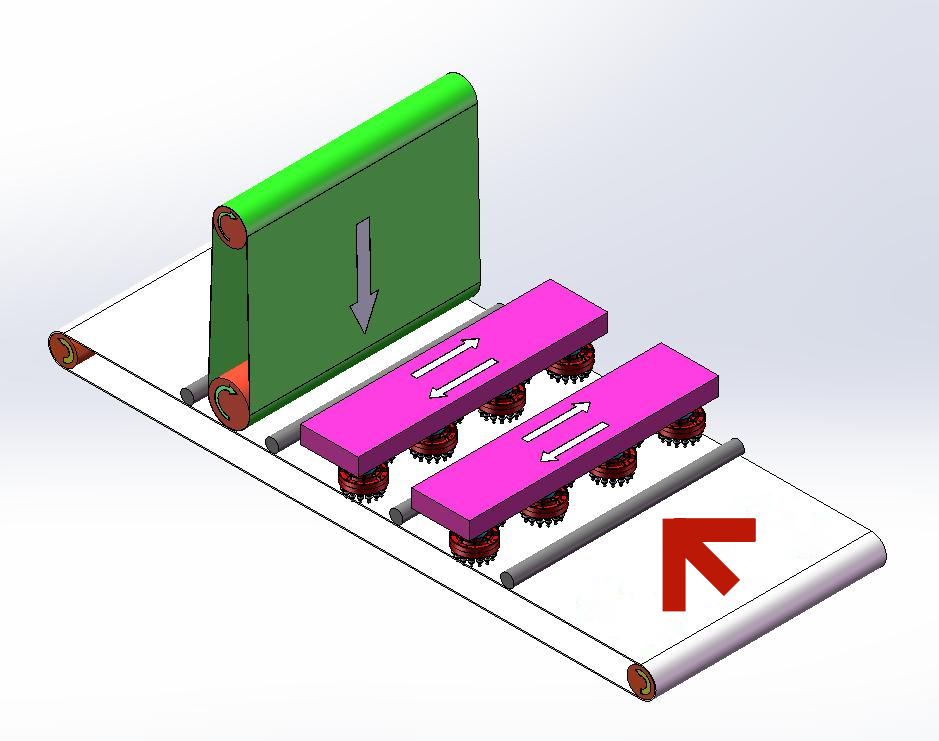

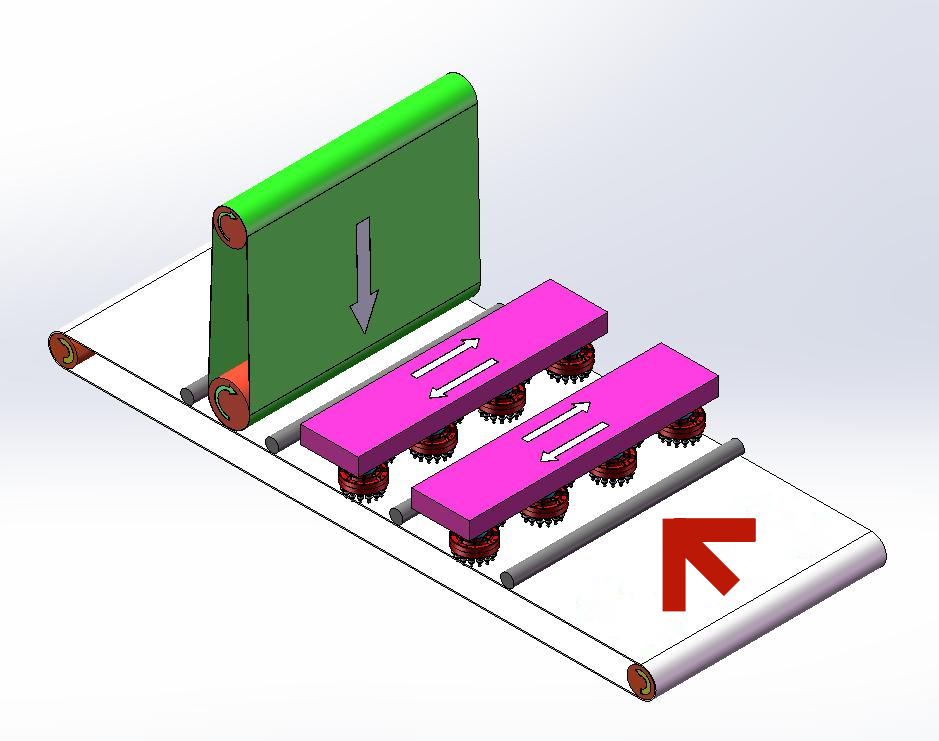

MSD-C650 Finishing Machine

The MSD-C650 is designed for high-efficiency deburring, edge rounding, and surface finishing of metal parts with precise quality and high throughput. It processes a variety of metal parts with excellent results.

Key Features:

First Station (Grinding Unit): Removes burrs and ensures a flat, burr-free surface.

Second Station (Oscillating Disc Brushes): Four brushes apply light pressure to ensure rounding of inner and outer contours.

Final Operation (Multibrush): Provides the final finishing touch, ensuring the product has a perfect, high-quality finish.

Main Technical Parameters:

| Parameter | Value |

| Processing Width | ≤ 600mm |

| Processing Thickness | 1 ~ 80mm |

| Minimum Processing Size | 50mm x 50mm |

| Total Machine Power | ≤ 33.95KW (excluding dust extraction) |

| Sand Belt Size | 1910 x 600mm |

| Steel Hammer Brush Diameter | Φ 162mm |

| Conveyor Speed | 0.5~6 m/min (adjustable) |

| Sand Belt Linear Speed | 18 m/s |

| Processing Thickness Servo Adjustment Accuracy | 0.01mm |

| Grinding Consumables | Steel hammer brush + abrasive belt |

| Dust Extraction Volume | 4000 m³/h |

| Approximate Equipment Dimensions | 2700mm (L) x 1700mm (W) x 2300mm (H) |

| Approximate Machine Weight | 2.2T |

This machine provides an efficient and reliable solution for deburring, edge rounding, and surface finishing, ensuring high-quality results and consistent performance for various metal parts. It is ideal for industries requiring precise and high-speed processing.