The 800mm Deburring and Edge Rounding Machine is designed specifically for sheet metal deburring and edge rounding applications, ideal for parts produced through laser cutting, punching, or shearing processes. This machine efficiently removes burrs and sharp edges from metal parts while providing smooth, rounded edges for improved safety, aesthetics, and functionality.

Features:

Dual Functionality: Capable of deburring and edge rounding, providing a high-quality finish on both the surface and edges of metal parts.

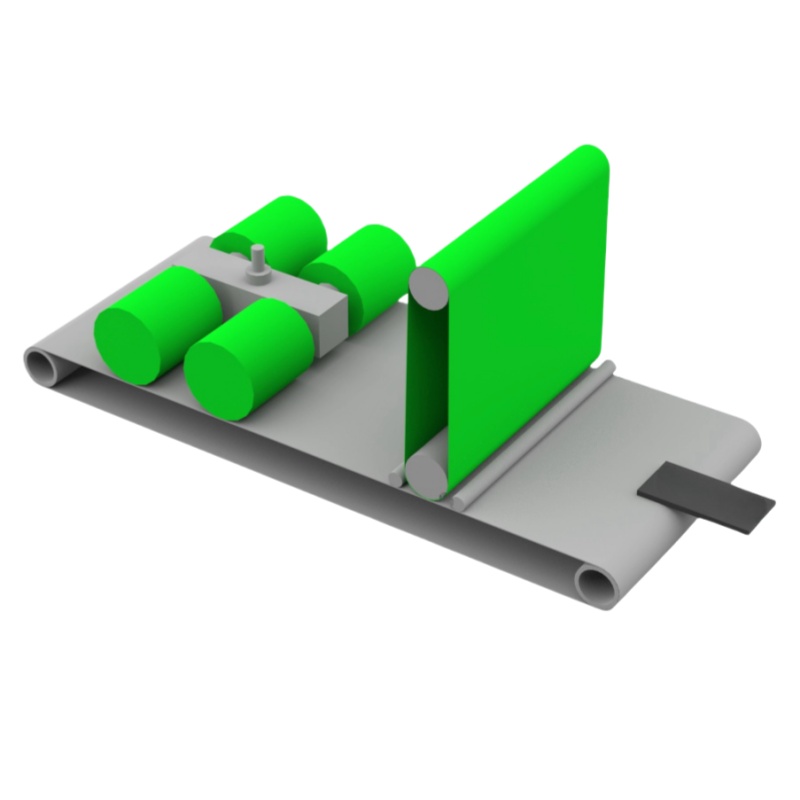

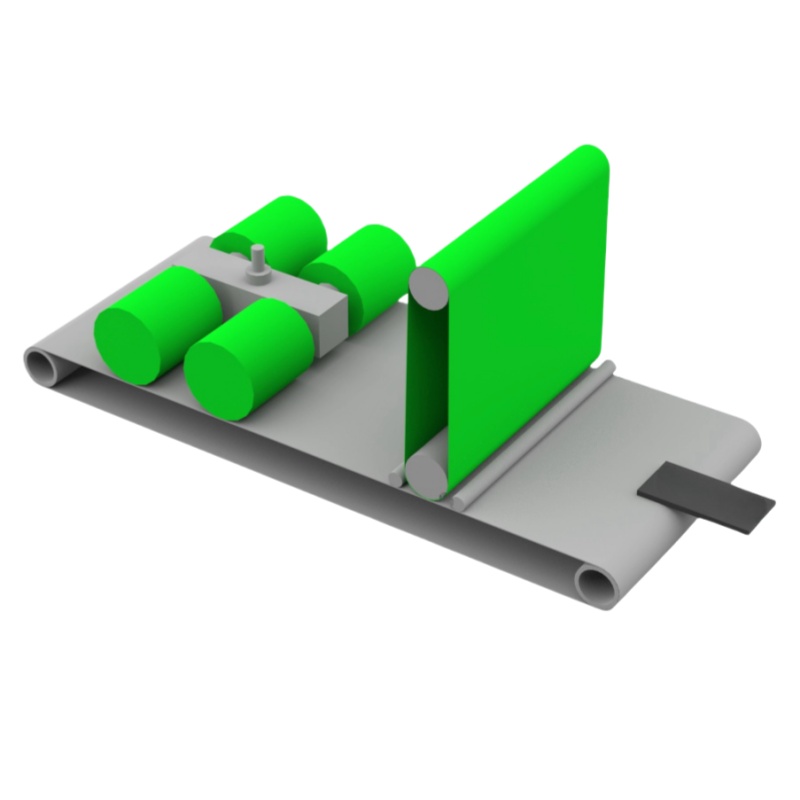

Flap Wheel and Grinding Belt: Equipped with 4pcs flap wheels and a grinding belt to ensure thorough deburring and edge rounding of both flat and irregularly shaped parts.

High Precision: Ensures consistent and uniform deburring and edge rounding, improving part quality and reducing the need for manual finishing.

Versatile: Can process various metals such as carbon steel, stainless steel, aluminum, and other non-ferrous metals.

Adjustable Settings: The machine allows for customizable settings based on part thickness and required finish, ensuring optimal results across a wide range of materials and applications.

Dust Extraction System: Includes an efficient dust collection system to maintain a clean working environment by extracting debris and particles produced during the deburring process.

Compact Design: Designed for easy integration into existing production lines, saving space while delivering high throughput.

User-Friendly Interface: Equipped with an intuitive control panel for easy operation, allowing quick adjustments to settings and parameters.

Applications:

Laser-Cut Metal Parts: Removes burrs and sharp edges from parts produced by laser cutting, improving safety and appearance.

Punched and Sheared Parts: Ideal for deburring and rounding the edges of metal parts that have been punched or sheared, reducing the risk of sharp edges.

Automotive and Aerospace Industries: Suitable for deburring and edge rounding metal parts used in automotive and aerospace components where precision and safety are critical.

Metal Fabrication and Stamping: A key tool for improving the quality and finish of stamped and fabricated parts, making them ready for further processing or assembly.

Technical Specifications:

| Parameter | Specification |

| Working Width | 800mm |

| Deburring and Rounding Tools | 4pcs Flap Wheel + Grinding Belt |

| Max Part Size | 800mm x 80mm (width x thickness) |

| Belt Speed | 10-20 m/s |

| Motor Power | 15kW (total) |

| Feeding Speed | Adjustable from 0.5 - 6m/min |

| Dust Extraction Connection | 100mm Ø (for dust collection) |

| Control Panel | PLC-based with digital interface |

| Power Supply | 380V, 50Hz |

| Machine Dimensions (LxWxH) | 2200mm x 1000mm x 1400mm |

| Weight | 2200 kg |

| Material Types | Carbon Steel, Stainless Steel, Aluminum, Non-Ferrous Metals |

| Safety Features | Emergency stop, overload protection, safety covers |

Benefits:

Efficiency: Capable of processing large volumes of sheet metal parts in a short time, improving production speed and efficiency.

Consistent Quality: Delivers uniform results across all parts, reducing the need for manual finishing and rework.

Low Maintenance: Designed for easy maintenance, reducing downtime and operational costs.

Environmental-Friendly: The integrated dust extraction system ensures a cleaner working environment by reducing airborne metal particles.