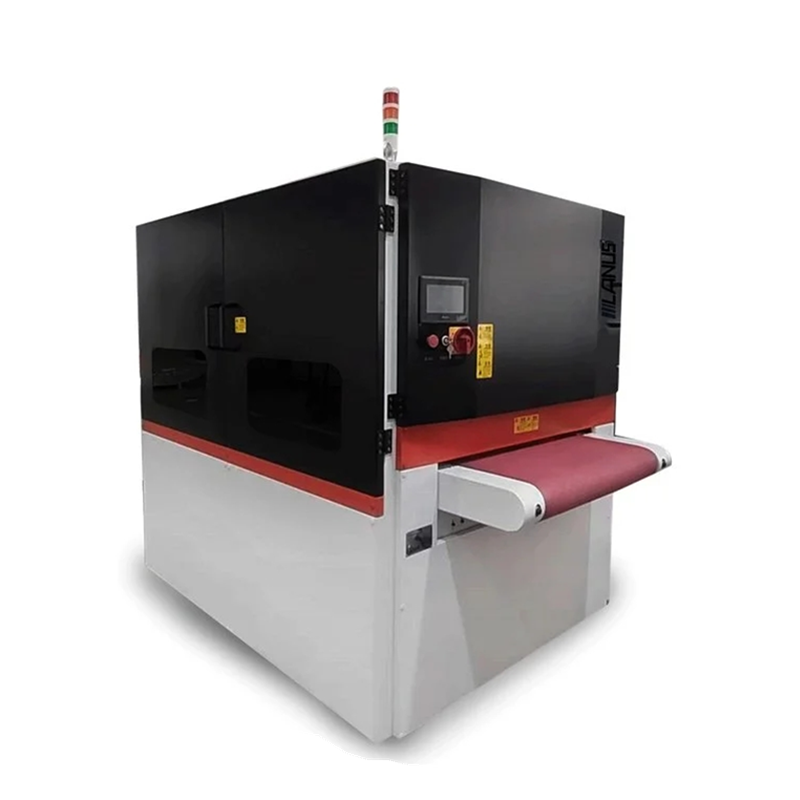

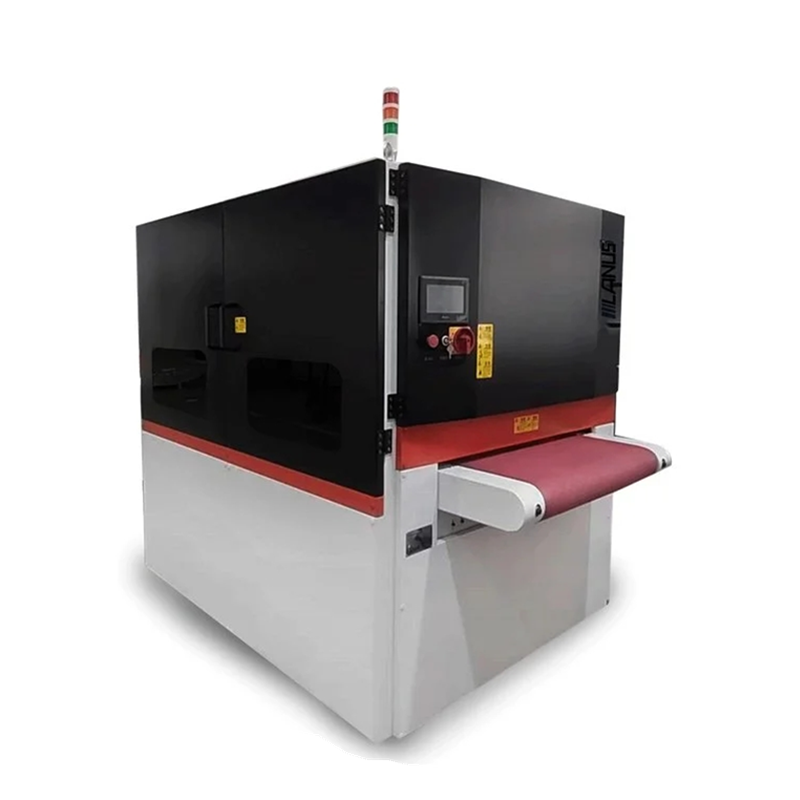

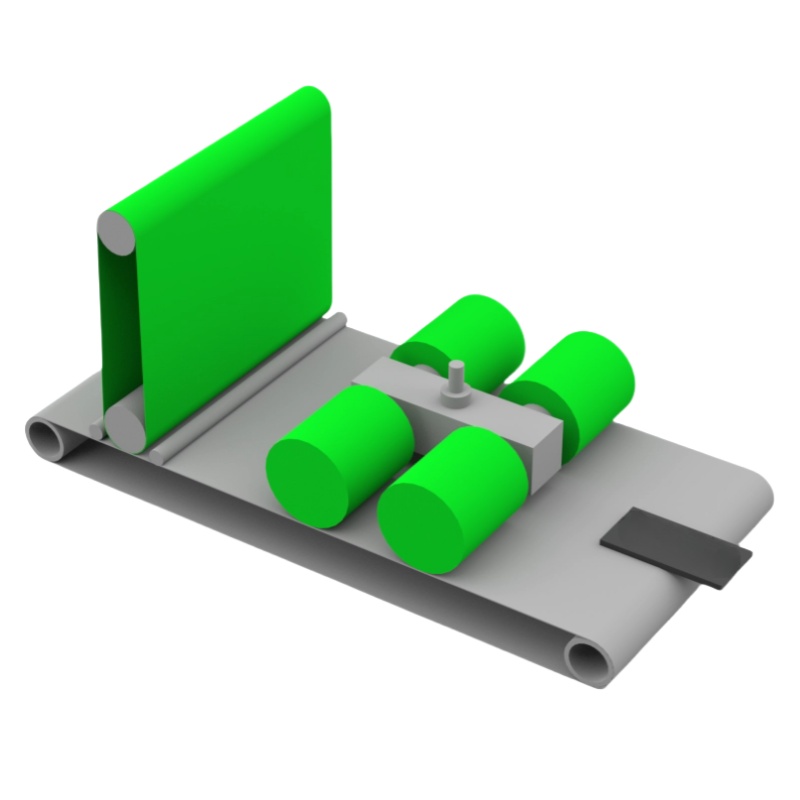

800mm Sheet Metal Deburring Machine

Deburring | Edge Rounding | Oxide Removal | Surface Finishing

For laser-cut, punched, sheared, or plasma-cut sheet metal parts

The 800mm sheet metal deburring machine is a high-performance solution designed for the deburring, edge rounding, and surface finishing of medium to large metal sheets. With a working width of 800mm, it accommodates a wide range of part sizes, making it ideal for fabricators, metal processors, and manufacturers seeking consistent, high-quality results with minimal labor.

This machine processes carbon steel, stainless steel, aluminum, copper, and other non-ferrous metals. It’s especially suited for parts with sharp edges, laser burrs, oxide layers, or welding scale.

⚙️ Key Features

Working Width: 800mm

Deburring & Edge Rounding

Oxide Removal & Finishing

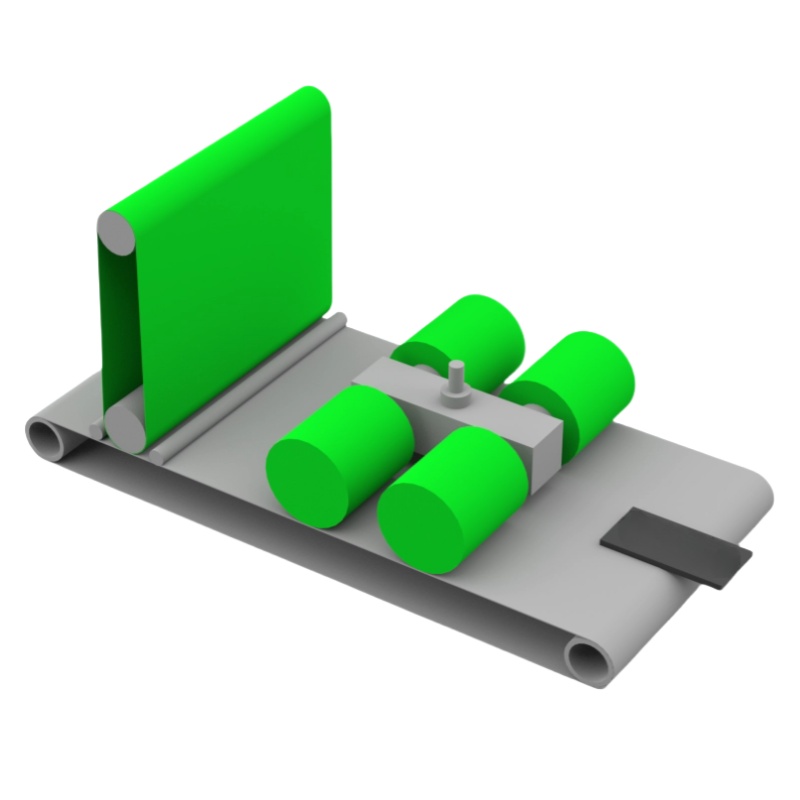

Multiple Configurations

Vacuum Bed or Conveyor Table

Typical Specifications

(May vary based on final configuration)

| Parameter | Specification |

| Working Width | 800mm |

| Part Thickness | 0.8mm – 80mm |

| Min Part Size | 50mm × 50mm |

| Feeding Speed | 0.5 – 6 m/min (adjustable) |

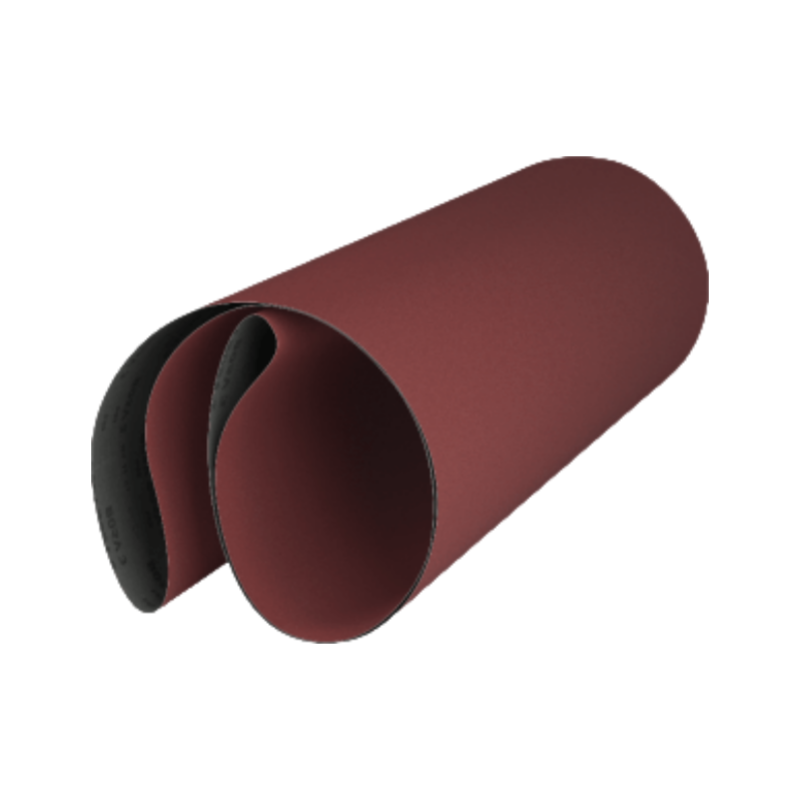

| Abrasive Belt Size | 1910mm × 800mm |

| Brush Diameter | 300mm |

| Main Motor Power | Up to 36.5 kW |

| Brush Rotation Speed | 500 – 1400 rpm |

| Dust Extraction Volume | ≥ 5000 m³/h |

| Machine Dimensions | L3050 × W2150 × H2150 mm |

| Machine Weight | ~3T |

Applications

✅ Laser-Cut Parts

✅ Punched and Plasma-Cut Sheets

✅ Burr and Slag Removal

✅ Oxide and Scale Removal

✅ Pre-Coating Surface Preparation

✅ Edge Rounding for Safety and Coating Adhesion

Advantages

Consistent Finishing: Uniform surface quality, no manual variation

High Throughput: Continuous feed processing for increased productivity

Safe & Clean: Integrated dust collection, safer edge quality

Versatile Materials: Handles all common industrial metals

Reduced Rework: Improves quality before powder coating, painting, or welding