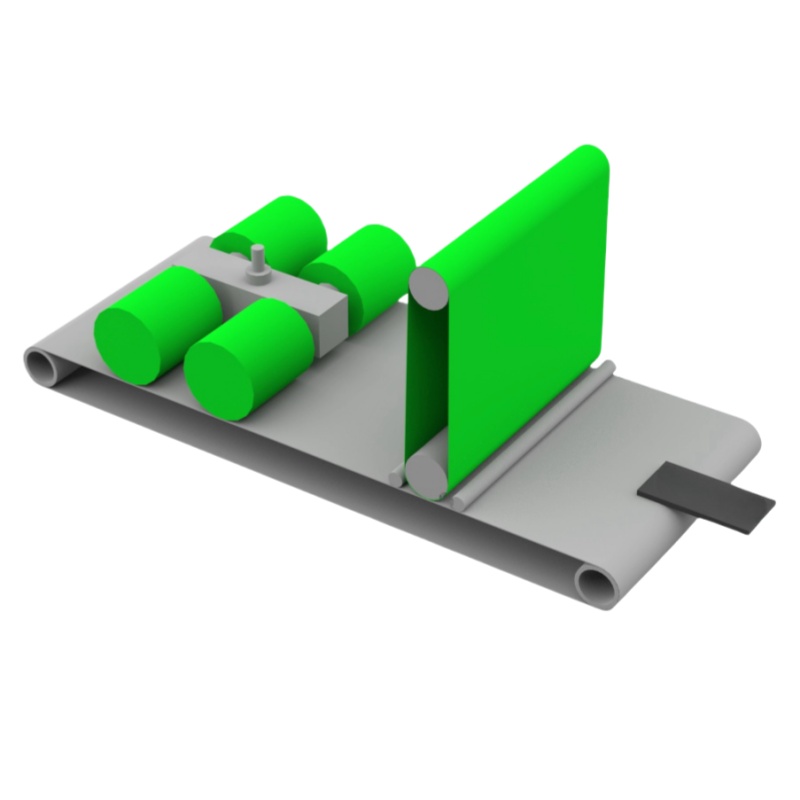

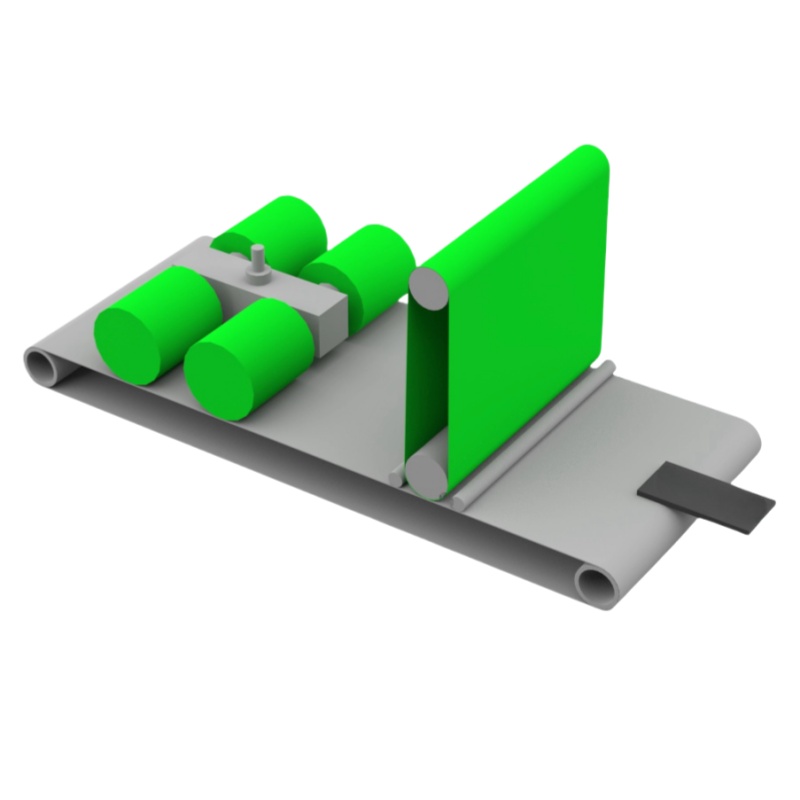

Sheet Metal Edge Deburring Machine for Processing Laser-Cut, Plasma-Cut, Waterjet-Cut, or Punched Sheet Metal Parts (Abrasive Belt Station & Rotary Brush Head)

The Sheet Metal Edge Deburring Machine is an advanced industrial solution designed for the effective deburring, edge rounding, and finishing of sheet metal parts. Whether the parts are laser-cut, plasma-cut, waterjet-cut, or punched, this machine is engineered to handle a wide variety of metal processing applications, ensuring consistent and high-quality results.

Key Features:

Abrasive Belt Station:

The abrasive belt station is equipped with high-performance belts that efficiently remove burrs and smooth sharp edges. The abrasive belt is ideal for contouring parts and preparing the surface for further processing or finishing. This station helps to remove imperfections such as sharp edges and rough surfaces, ensuring a polished finish.

Rotary Brush Head:

The rotary brush head is designed to provide 360° processing for edge rounding and oxide removal. It works by counter-rotating and oscillating around the metal parts, delivering even, consistent edge rounding. The machine can round edges up to 1.5 mm radius, providing a smooth and professional finish to metal parts.

High-Quality Deburring:

The machine's combination of abrasive belt and rotary brush head ensures high-quality deburring from all angles. It effectively removes burrs from laser-cut, plasma-cut, waterjet-cut, and punched parts, preparing the workpieces for further processing or assembly.

Adjustable Brush Settings:

Uniform Edge Rounding:

The machine ensures uniform edge rounding, creating a consistent radius on the edges of the metal parts. This is essential for both aesthetic purposes and safety, especially in applications where sharp edges could be hazardous or cause issues during assembly.

Oxide Removal:

For parts that have undergone laser cutting or other heat-based processes, the machine also features oxide removal capabilities. The rotary brush head effectively removes the oxide layer, improving the quality and cleanliness of the metal surface.

Versatile Material Compatibility:

This machine is suitable for processing a variety of materials, including stainless steel, aluminum, carbon steel, and non-ferrous metals. It is ideal for industries such as automotive, aerospace, metal fabrication, and electronics.

High Precision and Efficiency:

The combination of abrasive belts and rotary brushes allows for precise, uniform processing, minimizing rework and maximizing efficiency. The machine can handle high-volume production runs while ensuring high-quality surface finishes.

Applications:

Laser-Cut Metal Parts: Effective deburring and oxide removal for parts with heat-affected zones.

Plasma-Cut Parts: Removes rough edges and improves part appearance.

Waterjet-Cut Parts: Finishes parts with precise edge rounding and burr removal.

Punched Parts: Smoothes edges, removes burrs, and prepares parts for further processes.

General Metal Deburring: Suitable for a wide range of metal processing tasks, including sheet metal deburring, finishing, and edge rounding.

Benefits:

Uniform Deburring and Edge Rounding: Ensures clean, smooth, and safe edges.

Dual-Functionality: Combines abrasive belt and rotary brush processing for efficient metal surface treatment.

Customizable Settings: Adjustable height and RPM for optimized processing based on part type.

Versatility: Can process a variety of materials, including stainless steel, aluminum, and carbon steel.

Improved Surface Quality: Removes burrs, oxide layers, and other imperfections for a polished finish.

Efficient Production: Capable of high-speed processing while maintaining quality standards.

Conclusion:

The Sheet Metal Edge Deburring Machine with abrasive belt station and rotary brush head offers a complete solution for deburring, edge rounding, finishing, and oxide removal. Its dual-functionality, versatility, and high precision make it an essential tool for industries dealing with laser-cut, plasma-cut, waterjet-cut, and punched sheet metal parts. Whether for small batches or high-volume production, this machine provides a reliable, efficient, and cost-effective way to achieve high-quality, clean, and safe metal parts.

Applications:

Deburring of laser-cut, plasma-cut, waterjet-cut, and punched metal parts.

Edge rounding and oxide removal for smooth, clean metal edges.

Finishing of sheet metal parts for further processing or assembly.