Introduction to AC220/380V 800kg Metal Plate Vacuum Lifter: Electric Vacuum Lifter for Sheet Metal

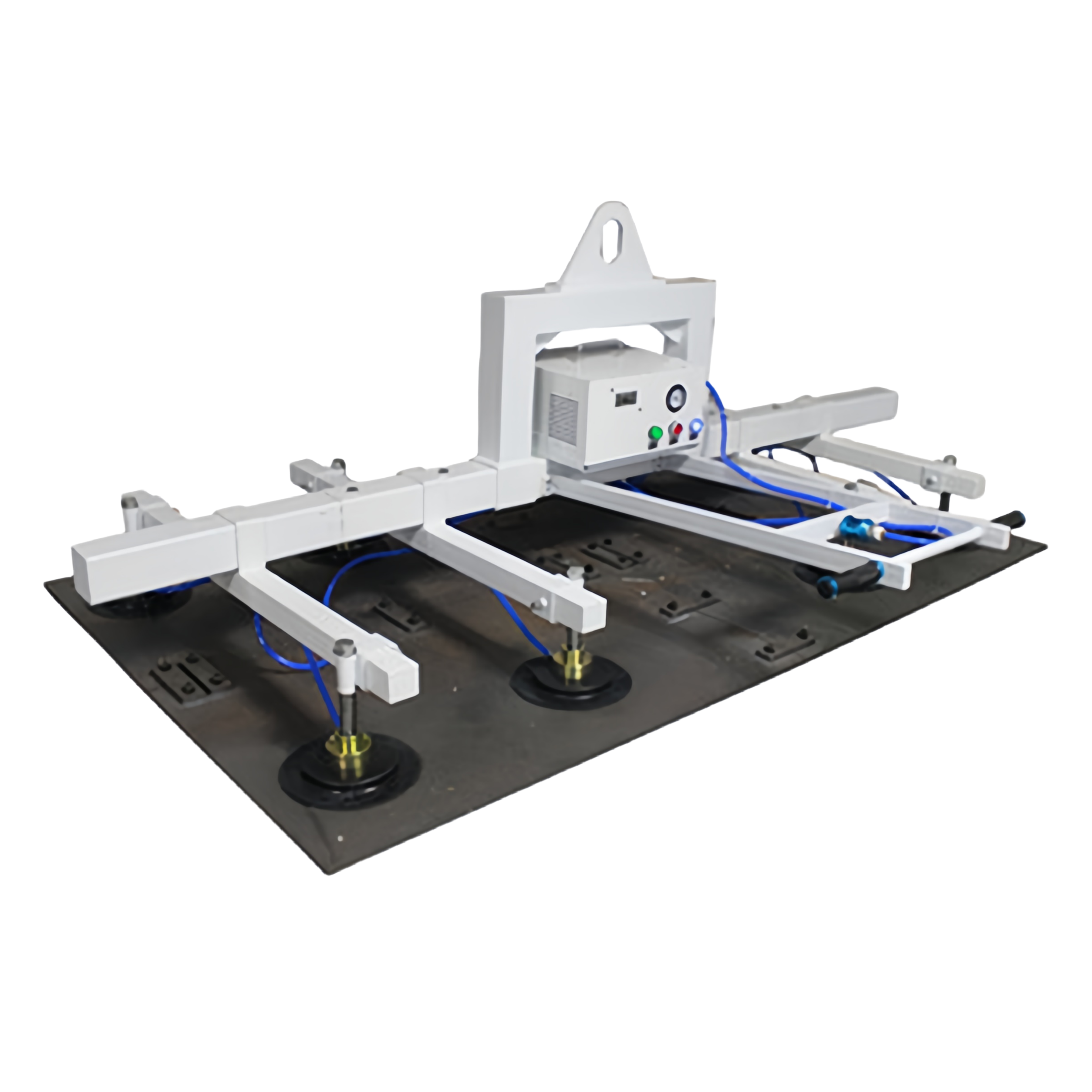

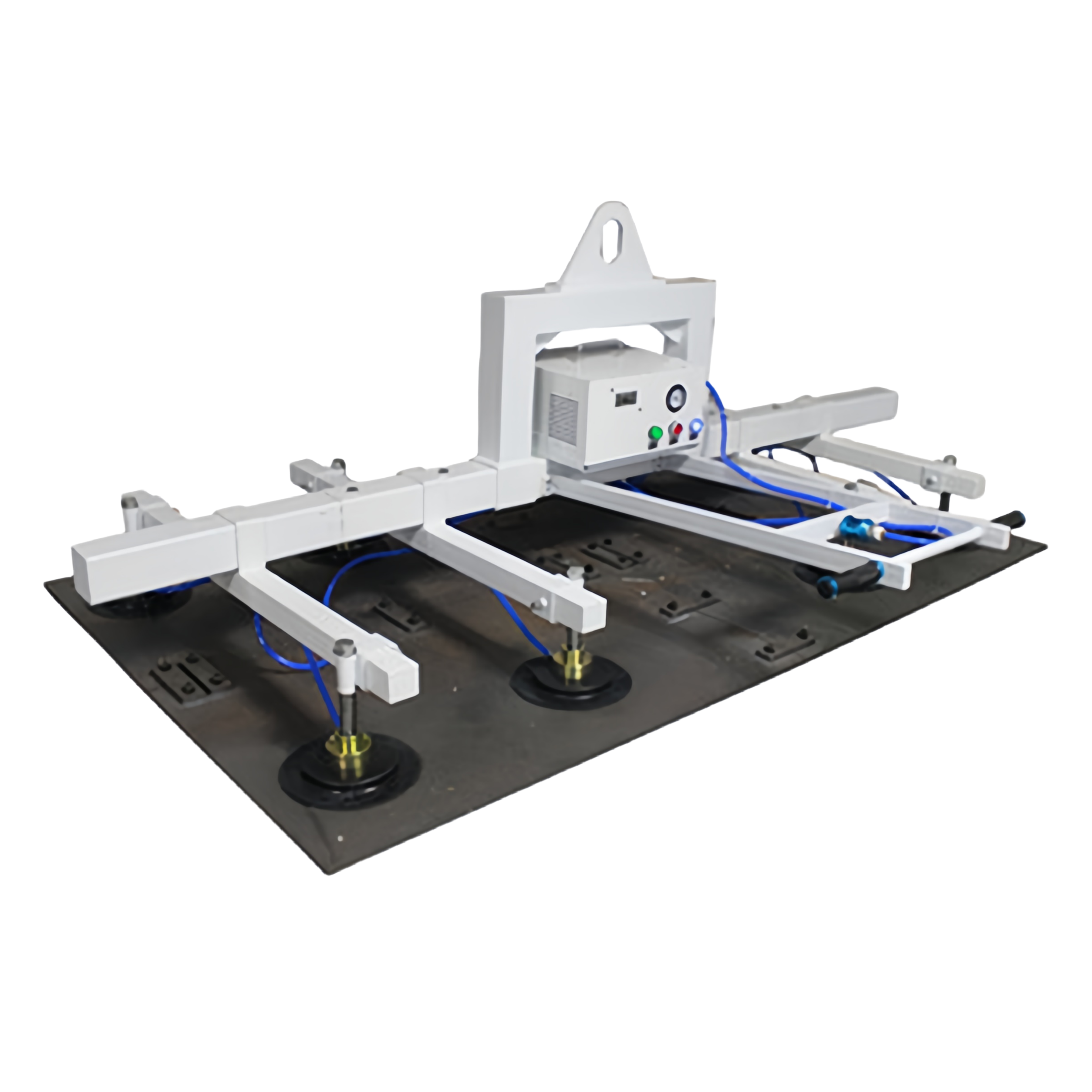

In today's industrial landscape, the efficient and safe handling of materials is crucial for maximizing productivity while minimizing downtime and workplace injuries. For industries dealing with heavy and often cumbersome materials like metal plates and sheet metal, having the right lifting equipment is essential. The AC220/380V 800kg Metal Plate Vacuum Lifter, an electric vacuum lifter for sheet metal, is engineered to address these challenges by providing an efficient, safe, and ergonomic solution for lifting and transporting heavy sheet metal and metal plates in manufacturing, construction, and metalworking industries. This vacuum lifter combines advanced electric technology with high load capacities, offering a versatile and reliable solution for material handling.

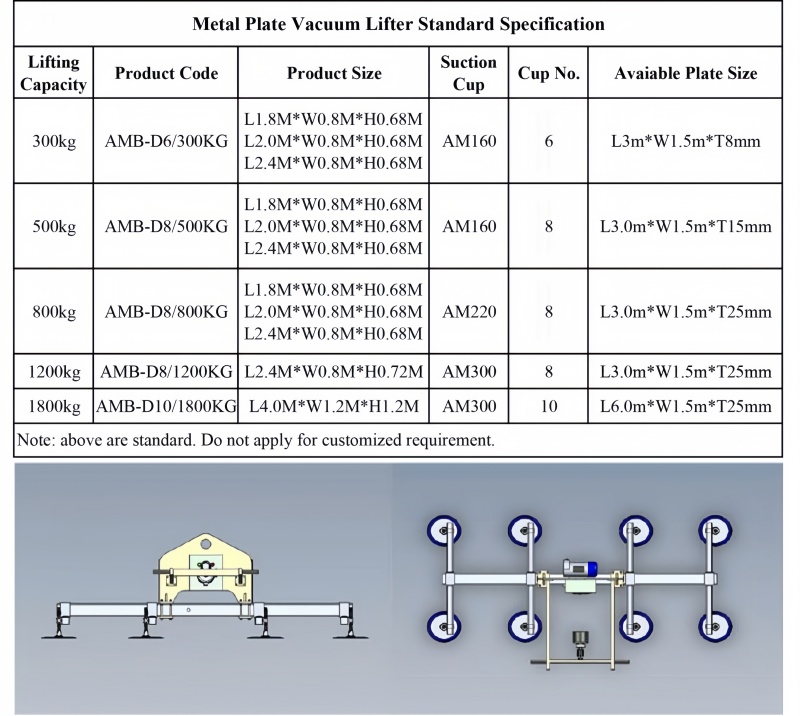

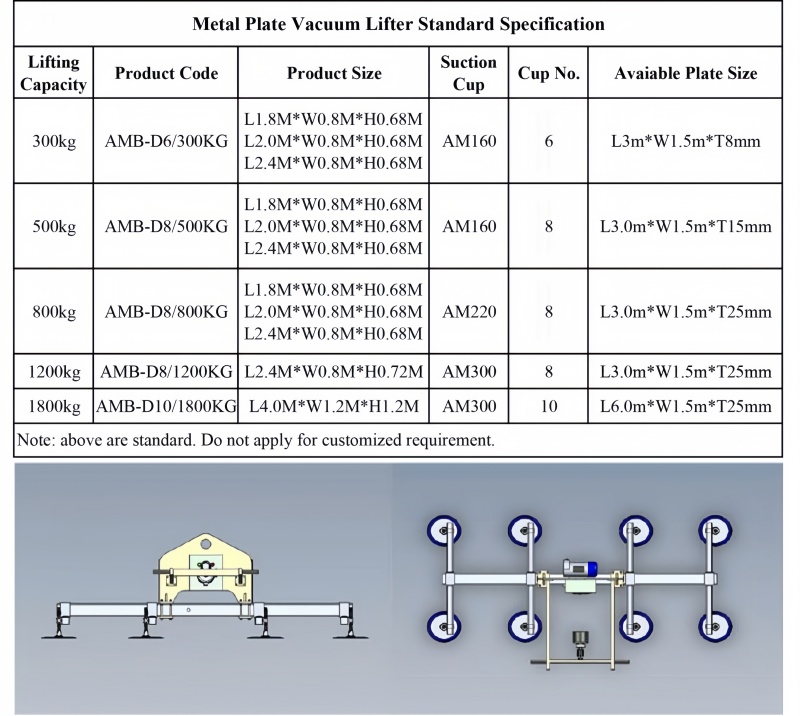

| Product Type | Pneumatic Lifter | Rechargeable Lifter | Plug-in Lifter |

| Model | JS-300-2M/3M | JS-JG300-2M/3M | JS-JG600-2M/3M | JS-JG800-2M/3M | JS-CG300-2M/3M | JS-CG600-2M/3M | JS-CG800-2M/3M |

| Rated Load (kg) | 300 | 300 | 600 | 800 | 300 | 600 | 800 |

| Suction Cup Diameter (mm) | 150 | 150 | 200 | 200 | 150 | 200 | 200 |

| Number of Suction Cups | 8 | 8 | 6 | 8 | 8 | 6 | 8 |

| Dimensions (mm) | 2000*1000 3000*1000 | 2000*1000 3000*1000 | 2000*1000 3000*1000 | 2000*1000 3000*1000 | 2000*1000 3000*1000 | 2000*1000 3000*1000 | 2000*1000 3000*1000 |

| Plate Size (mm) | 3000*1500 4000*2000 | 3000*1500 4000*2000 | 3000*1500 4000*2000 | 3000*1500 4000*2000 | 3000*1500 4000*2000 | 3000*1500 4000*2000 | 3000*1500 4000*2000 |

| Operating Power (V) | 0.8MPa Air Source | DC12V | DC12V | DC12V | AC220V/380V | AC220V/380V | AC220V/380V |

Key Features and Benefits

1. High Load Capacity of 800kg

One of the standout features of the AC220/380V 800kg Metal Plate Vacuum Lifter is its ability to handle large and heavy materials, with a maximum lifting capacity of up to 800kg. This makes it an ideal tool for industries that require lifting and transporting substantial sheets of metal, steel, or aluminum. Whether you're working with thick metal plates for construction, heavy steel sheets for automotive manufacturing, or large aluminum panels for industrial applications, this vacuum lifter is designed to handle the job efficiently.

By utilizing vacuum technology, this lifter ensures that metal plates, no matter how heavy, can be safely and easily moved, which would otherwise require multiple workers or heavy lifting machinery. With the 800kg load capacity, this vacuum lifter enables businesses to handle a wide range of panel materials, reducing the need for additional lifting equipment or cranes.

2. Electric Operation for Ease of Use

The electric operation of the AC220/380V Metal Plate Vacuum Lifter provides a major advantage over manual and pneumatic systems. Powered by AC220/380V electricity, this system delivers consistent, reliable, and powerful suction capabilities to lift heavy loads with ease.

Electric vacuum lifters are favored for their ease of use and maintenance. Operators can control the lifting, moving, and lowering of materials with a push-button control panel, allowing for precision and effortless movement. The system also eliminates the need for compressed air or additional fuel sources, making it a more energy-efficient and cost-effective solution compared to pneumatic lifters. This electric-powered vacuum lifter improves efficiency while providing a safer and more ergonomic lifting experience.

3. Precise and Secure Handling of Sheet Metal

Handling large metal plates and sheets requires not only strength but also precision. Vacuum lifting technology provides an incredibly secure grip on sheet metal without causing damage, such as bending, scratching, or denting. The suction cups and suction pads on the lifter are carefully designed to provide a firm yet gentle grip on the surface of the metal, ensuring that the sheets are held securely during lifting and transport.

The AC220/380V Metal Plate Vacuum Lifter is designed with adjustable suction pads to accommodate different sizes of sheet metal and metal plates. Whether you’re lifting small metal sheets or large metal panels, the suction cups can adjust to the material’s size and surface characteristics, ensuring the lifting process is both efficient and secure.

4. Ergonomically Designed for Worker Safety and Comfort

Manual handling of metal plates and sheets often leads to worker strain, fatigue, and injuries. The AC220/380V 800kg Metal Plate Vacuum Lifter significantly reduces these risks by providing an ergonomic and user-friendly solution for lifting and handling metal sheets.

The lightweight design and easy-to-operate controls ensure that the operator doesn’t have to exert excessive physical effort. The vacuum lifter minimizes the need for workers to engage in lifting or carrying heavy materials, thus reducing the risk of muscle strain or back injuries. Additionally, the vacuum lifter can be mounted on manual trolleys, overhead cranes, or stationary lifting systems depending on the specific needs of the operation.

5. Advanced Safety Features

Safety is a top priority when dealing with heavy loads like sheet metal and metal plates. The AC220/380V Metal Plate Vacuum Lifter is equipped with a range of built-in safety features designed to prevent accidents and ensure the safety of both the operators and the materials being lifted. These include:

Vacuum Monitoring System: This feature continuously monitors the vacuum pressure to ensure that the suction pads maintain a secure grip on the material. If the vacuum level drops below a safe threshold, the system will alert the operator, preventing material slippage or accidental drops.

Overload Protection: The lifter is designed with overload protection to prevent damage to the machine and avoid accidents when lifting materials beyond the specified load capacity.

Emergency Shut-off: In case of any emergency or malfunction, the emergency shut-off button allows the operator to quickly deactivate the system and halt the lifting process, ensuring safety at all times.

Automatic Locking Mechanism: Once the material is lifted, the vacuum pads are automatically locked in place, preventing unintentional detachment.

These features provide the operator with peace of mind, knowing that the system has been designed to handle materials safely while minimizing the risks of accidents in the workplace.

6. Versatility and Adaptability

The AC220/380V 800kg Metal Plate Vacuum Lifter is highly versatile and can be adapted to suit a wide range of lifting and handling needs. The lifter is suitable for a variety of materials, including metal plates, steel sheets, aluminum panels, copper sheets, and other large, flat materials.

Moreover, this vacuum lifter can be integrated into existing systems, whether that be overhead cranes, hoist systems, or fixed lifting stations, enhancing its versatility across different types of operations. Its flexibility makes it particularly beneficial for industries like:

Metalworking and Fabrication: Handling large metal plates during cutting, welding, or painting processes.

Construction and Installation: Lifting heavy panels for building facades or construction projects.

Automotive Manufacturing: Moving large metal sheets during car body assembly or component production.

Logistics and Warehousing: Lifting and moving heavy metal or aluminum sheets in distribution centers.

7. Energy Efficiency and Cost-Effectiveness

One of the key advantages of the electric vacuum lifter is its energy efficiency. Unlike pneumatic lifters, which require a constant supply of compressed air, electric vacuum lifters like the AC220/380V 800kg Metal Plate Vacuum Lifter draw power directly from the electricity supply, which is typically more cost-effective and energy-efficient.

The electric operation reduces the need for costly air compressor systems and eliminates the ongoing maintenance costs associated with pneumatic lifters. Additionally, the reliable power source and lower operational costs result in reduced total cost of ownership, making it a smart investment for companies looking to increase their operational efficiency without overspending on energy or equipment upkeep.

8. Low Maintenance and Long-Lasting Performance

The AC220/380V Metal Plate Vacuum Lifter is designed to be low-maintenance, offering long-lasting performance with minimal upkeep. The vacuum system has few moving parts, which reduces wear and tear and ensures longevity. Moreover, the suction cups and seals are made from durable, high-quality materials that can withstand the harsh conditions of industrial environments.

Routine maintenance primarily involves checking the vacuum pressure and inspecting the suction pads for wear, which is straightforward and can be done quickly to ensure continued optimal performance. This ease of maintenance ensures that the vacuum lifter remains operational and reliable over time, minimizing downtime and boosting productivity.

Applications of the AC220/380V 800kg Metal Plate Vacuum Lifter

The AC220/380V 800kg Metal Plate Vacuum Lifter is ideal for various industries that require the lifting and transport of large, heavy materials. Some of the key applications include:

Metalworking and Fabrication: In industries such as steel processing, aluminum fabrication, and metal stamping, the lifter is used to move large metal sheets to and from machines like cutting, pressing, and welding stations.

Automotive Manufacturing: The lifter can be used to handle large steel panels and aluminum sheets during the construction of vehicle bodies and components.

Construction and Building: For lifting metal panels or prefabricated elements during the construction of buildings and infrastructure.

Glass Handling: Lifting large glass panels safely without damage, ensuring delicate surfaces are moved with precision.

Warehouse and Logistics: Moving metal plates or other heavy materials across warehouses, distribution centers, or production lines.