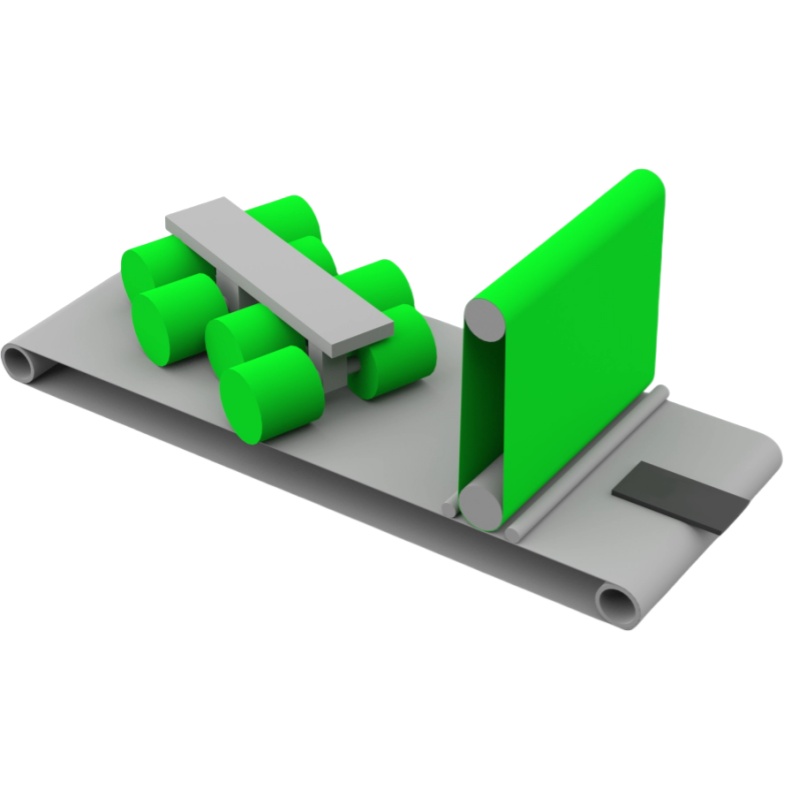

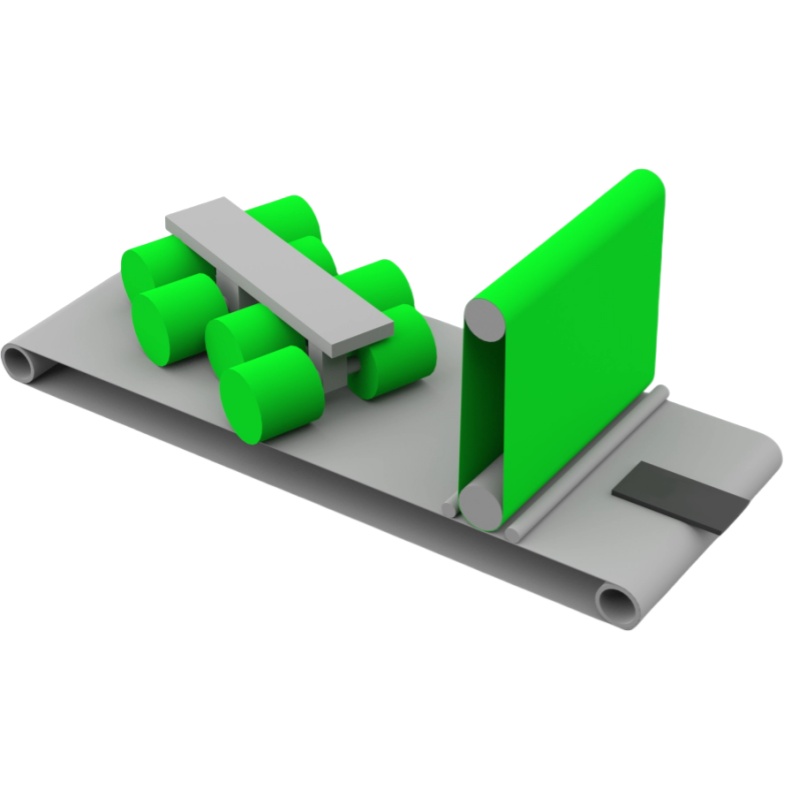

1350mm Deburring Machine for Punching / Stamping with Laser Oxide Removal

Sanding Belt + Flap Wheel Brushes

Product Overview

The 1350mm Deburring Machine for Punching and Stamping with Laser Oxide Removal is an advanced metal finishing solution tailored for high-precision deburring, surface polishing, and oxide removal on a wide range of metals including stainless steel, carbon steel, aluminum, copper, and other non-ferrous alloys. This machine integrates a heavy-duty sanding belt station with multiple flap wheel brush units to provide efficient burr removal, edge rounding, and superior surface treatment in a single, continuous pass.

Key Features

Wide Material Compatibility: Suitable for stainless steel, carbon steel, aluminum, copper, and various non-ferrous metals.

Complete Burr Removal: Thoroughly removes burrs and slag generated by punching, stamping, laser cutting, plasma cutting, shearing, and flame cutting processes.

Laser Oxide Removal: Effectively eliminates oxide layers and surface discoloration, restoring metal brightness and improving corrosion resistance.

Precision Edge Rounding: Produces uniform small-radius (R-arc) edges on all part edges and holes for enhanced safety and quality.

Combined Sanding and Brushing System: The sanding belt removes large burrs and surface imperfections, while flap wheel brushes refine edges and polish surfaces with gentle, controlled abrasion.

Adjustable Operating Parameters: Variable frequency drives control the sanding belt speed, brush rotation, and conveyor speed to optimize processing for different materials and thicknesses.

Protective Surface Treatment: Abrasive materials are carefully selected to avoid damage to coatings or protective films, ensuring delicate parts are processed safely.

Integrated Wet Dust Collection: Equipped with a wet dust collector system that efficiently traps grinding dust, ensuring a clean and safe workplace environment.

User-Friendly Controls: PLC system with touchscreen interface simplifies operation, monitoring, and maintenance.

Applications

Deburring and edge rounding of punched and stamped metal parts.

Laser oxide removal for improved metal surface quality and corrosion resistance.

Surface polishing and finishing to enhance aesthetics and prepare for further processing.

Removal of burrs and slag from laser-cut, plasma-cut, and flame-cut metal sheets.

Technical Specifications

Processing Width: Up to 1350mm

Processing Thickness: 0.5mm to 80mm

Minimum Processing Size: 50mm × 50mm (solid workpieces)

Total Power: Approximately 50KW

Sanding Belt Size: Φ1910mm × 1350mm

Flap Wheel Brush Diameter: Typically 300mm to 400mm

Conveyor Speed: 0.5 to 6 m/min, frequency adjustable

Dust Extraction Volume: Approximately 5000 m³/h

Machine Dimensions: Approx. Length 3800mm × Width 2300mm × Height 2400mm

Machine Weight: Approximately 5 tons

Product Overview:

This 1350mm wide deburring and oxide removal machine is specially designed for comprehensive edge rounding, surface brushing, polishing, and laser oxide removal of various sheet metal materials, including stainless steel, carbon steel, aluminum, copper, and non-ferrous metals.

Combining a dry sanding belt station with eight sets of universal sanding disc roller brushes, the machine delivers uniform edge rounding (R-arc), inner hole deburring, and oxide layer removal — all in a single pass. It is ideal for burrs generated during laser cutting, stamping, punching, plasma cutting, and flame cutting, ensuring a smooth, safe, and high-quality finish.

⚙️ Key Functions & Applications:

✅ Edge Rounding (R0.2–R2 mm radius, adjustable)

✅ Laser Oxide Removal

✅ Surface Polishing and Hairline Finishing

✅ 360° Deburring for complex contours and inner holes

✅ Pre-Coating / Pre-Welding Surface Prep

✅ Slag Removal and fine surface cleaning

Processing Capabilities:

Suitable Materials: Stainless steel, carbon steel, aluminum, copper, non-ferrous metals

Processes Supported: Stamping, laser cutting, shearing, plasma/flame cutting

Part Size: Minimum 50mm × 50mm (solid workpieces), with optional fixtures for special shapes

Vacuum + Magnetic Workholding: Ensures safe, accurate pass-through processing

Working Principle:

Sanding Belt Station: Removes large surface burrs and slag from the metal surface

Eight Universal Disc Brush Rollers:

Adjacent rollers rotate in opposite directions

Complete unit revolves for high-speed grinding, filing, scraping

Produces even edge rounding and inner hole deburring

Independent Operation:

Each station can work separately for brushing, oxide removal, or deburring

Ideal for coated or sensitive sheet metals due to soft abrasive media

Dust Collection:

Wet-type dust extraction filters grinding residue with water spray

Captures fine metal dust, improves workplace safety, and enables metal powder recycling

Technical Specifications:

| Parameter | Specification |

| Max Processing Width | ≤1320 mm |

| Processing Thickness | 0.5 – 80 mm |

| Min Workpiece Size | 50 × 50 mm (solid parts) |

| Total Machine Power | 50 kW |

| Abrasive Belt Size | Φ1910 × 1350 mm |

| Disc Brush Size | Φ300 × 400 mm |

| Conveyor Speed | 0.5 – 6 m/min (VFD adjustable) |

| Belt Linear Speed | 18 m/s |

| Brush Rotation Speed | 8 – 26 m/s (VFD adjustable) |

| Brush Revolution Speed | 1 – 15 rpm (VFD adjustable) |

| Planetary Rotation Brush Heads | 8 pcs |

| Planetary Revolution Units | 1 pcs |

| Servo Adjustment Precision | 0.01 mm (thickness + compensation) |

| Grinding Media | Abrasive belt + Rotary brush |

| Dust Extraction Volume | 5000 m³/h |

| Machine Dimensions (L×W×H) | 3800 × 2300 × 2400 mm |

| Machine Weight | Approx. 5 Tons |

Main Equipment Configuration:

| Component | Specification/Brand |

| Sanding Motor | 15kW (Shiyang) |

| Brush Rotation Motors (x4) | 11kW (Shiyang) |

| Brush Revolution Motor | 1.5kW (Shengbang) |

| Servo Motors (Lifting & Compensation) | 750W (Weichuang) |

| Conveyor Motor | 3kW (Leibo) |

| Conveyor Reducer | EKAZ87 (Leibo) |

| Vacuum Fan Motor | 18kW (Jiuzhou) |

| Dust Control Inverter | 18kW VFD (Weichuang) |

| Tracking Sensor | Shanghai Hugu |

| Cylinders | Airtac (Tension: ACQ100×30 / Tracking: SDA63×5) |

| Electrical Components | CHINT |

| Bearings | NSK High-Speed Series |

| Control System | PLC + 7-inch HMI Touchscreen (Weichuang) |

Environmental & Safety Features:

Wet Dust Collection with water spray

Filtered clean air discharge

Metal powder recycling

Stable vacuum and magnetic workholding

Minimal operator exposure to airborne dust

Key Advantages:

High Throughput: Pass-through design for mass production

Consistent Quality: Uniform finish on every part, regardless of geometry

Cost Efficiency: Lower cost per part vs. manual processing

Safe & Clean: Dust filtration + vacuum hold-down for safe operation

Flexible Operation: Modular units allow independent or combined use