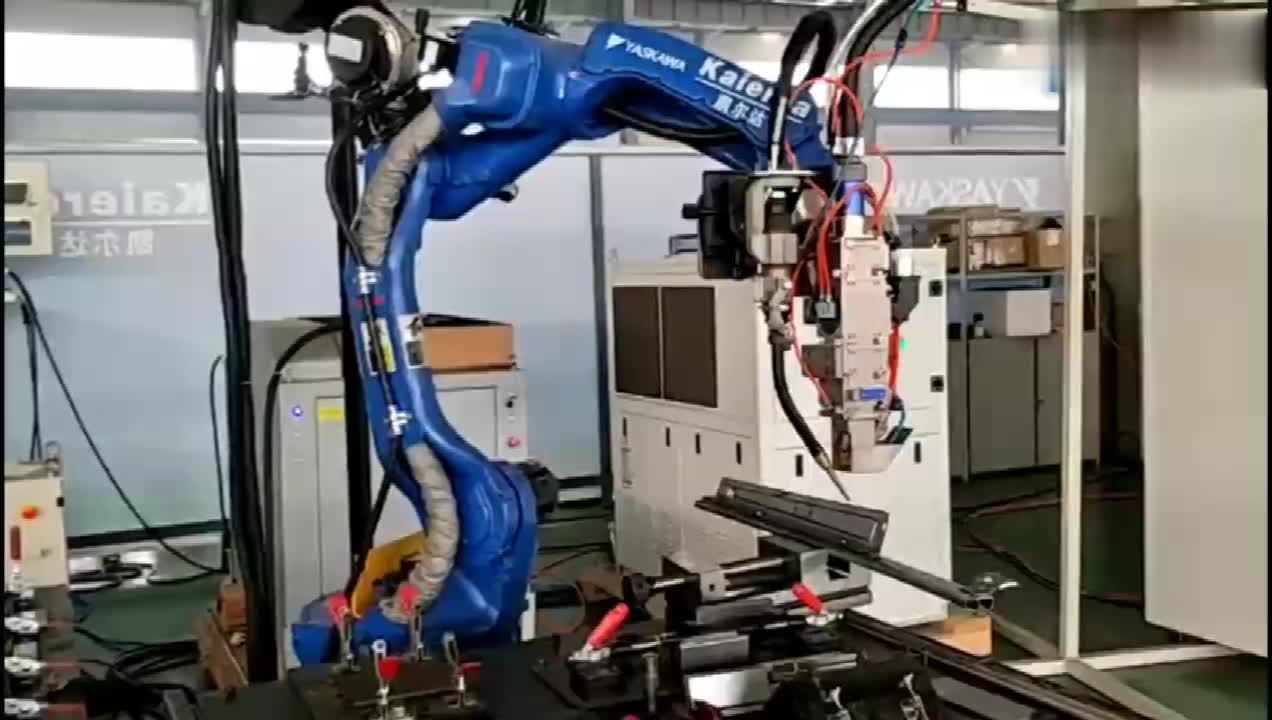

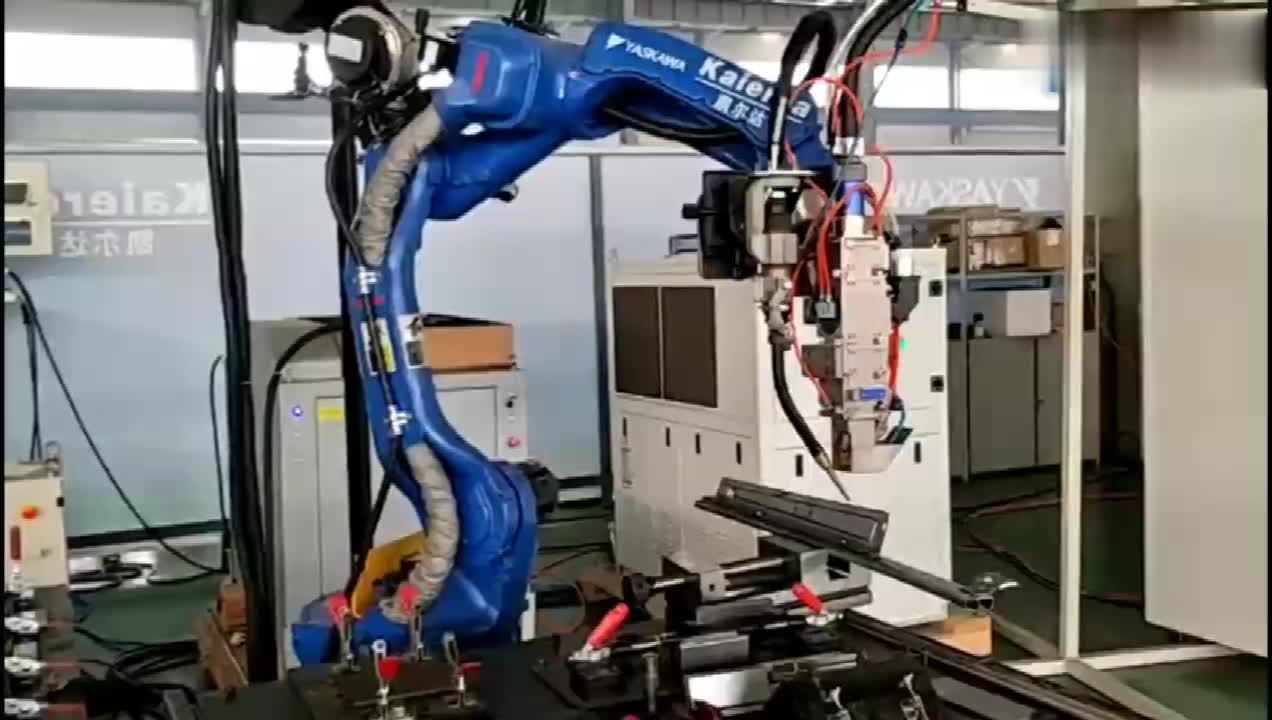

CNC Laser Robot Welding Machine with 6 Axis Robotic Process Automation

Six axis robot laser welding system

Robot Welding Machine

1. High precision, fast speed, and good usability to greatly improve production efficiency;

2.Easy to operate after simple training;

3. The safety function is further upgraded to monitor the welding position in real-time;

4. The six-axis structure is flexible in welding, which greatly improves the welding quality;

5.Standard and reasonable robot routing design, which improve effectively the cable life in the process of motion;

6.Customizable to meet your various needs

Application

Welding of metal materials in transportation, electronics, household hardware, and other industries.

Brief description of six-axis robot laser welding system

1.1 Introduction of six-axis robot

1.1.1 Model diagram (for reference) - six-axis robot laser welding machine

1.1.2 The six-axis robot is the most typical robot configuration

It is mainly composed of joints and connecting rods. The robot arm and wrist cooperate

to complete the target trajectory movement, with 6 degrees of freedom in space.

1.1.3 What are the six axes of a six-axis collaborative robot?

Generally speaking, a common six-axis robot consists of rotation (S axis), lower arm (L axis), upper arm (U axis), wrist rotation (R axis), wrist swing (B axis) and wrist rotation (T axis), etc. The 6-joint structure and the synthesis of 6 joints realize the 6-degree-of-freedom movement of the end,which makes the 6-axis collaborative robot have many advantages such as high flexibility, super large load, and high positioning accuracy.

1.1.4 What is the role of each axis of a six-axis robot?

First axis:

It is the position of the link chassis, the load-bearing and core position, which carries the

weight of the entire robot and the large swing of the robot left and right.

The second axis: it is mainly an important axis to control the robot to swing back and forth and stretch.

Third axis:

It controls the robot to swing back and forth, but the swing range is much smaller than

that of the second axis, but this is also determined by the arm span of the six-axis robot.

The fourth axis: It is an axis that controls the 180° free rotation of the upper arm, which is equivalent to the human forearm.

Fifth axis: It is very important. When you have almost adjusted the position and accurately positioned on the product, you need to use the fifth axis, which is equivalent to the human wrist.

Sixth axis:

After the fifth axis is positioned on the product, some minor changes are required, and the sixth axis is required. The sixth axis is equivalent to a turntable that can rotate 360 °

horizontally. Products can be positioned more precisely

1.1.5 Mechanical moving part of the shaft

Each axis is moved by a set of servo motor and precision reducer, and the reducer is divided into

RV reducer and harmonic reducer

1.1.6 Axis motion control and system composition

The movement between the axes is controlled by the control system of the robot. The hardware part of the control system is an industrial control board, while the software part is a

control algorithm.

The robot laser welding system is a comprehensive laser industry application integrating

machinery, electricity, software algorithms, laser technology, etc.

Now it has entered the rapid development channel. With the rapid development of

software algorithms, vision and machinery in our country, it will be a trend in the future!