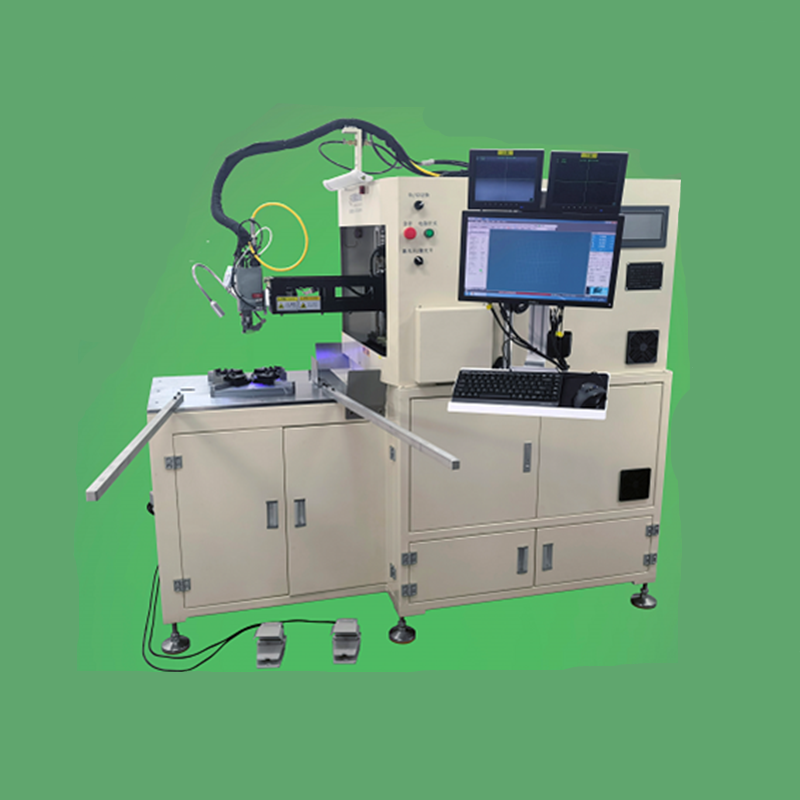

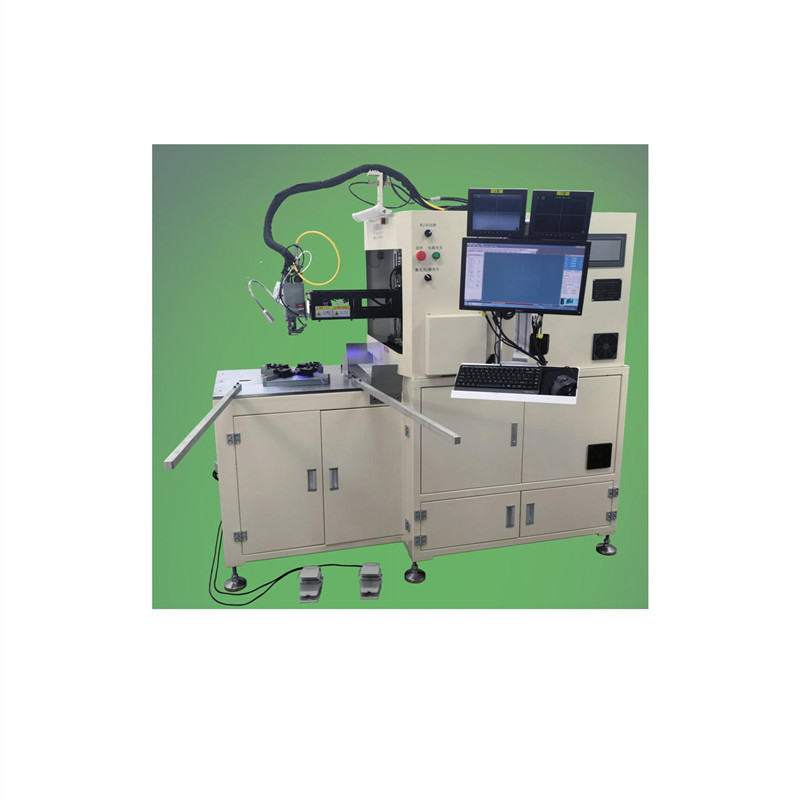

Double-head dual-station laser welding machine for aluminium frames

1.This equipment is mainly used in the welding of LED aluminium profiles, our company has developed this equipment according to years of experience in welding aluminium frames and profiles and according to customer requirements, the characteristics of this equipment are as follows.Advanced laser welding process, stable welding process, beautiful weld path, small product deformation,good strength;

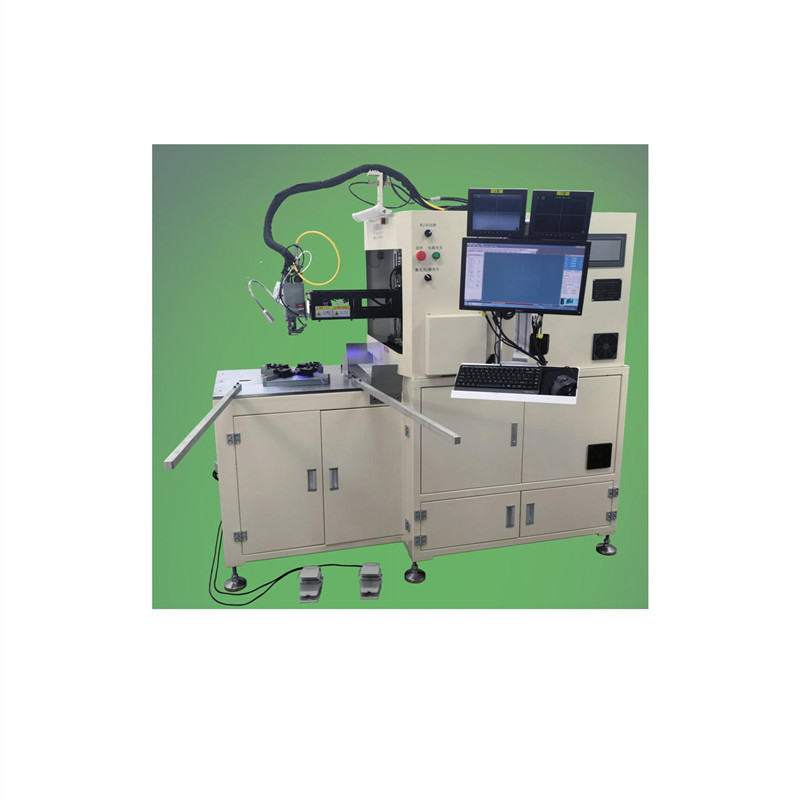

1. double-ended welding, front and back in one go, high efficiency and reduced manual turning.

2.The machine has a double-station structure, which allows the machine to be operated while feeding and welding, increasing productivity and reducing the purchase cost of the machine. The machine can be operated by 1 person at the same time and can be matched flexibly according to requirements.

3. This equipment can be equipped with optional wire filling function, customers can choose whether to fill the wire according to the product welding characteristics, because the laser belongs to the fine welding, the amount of wire filling and welding position can be controlled, the welding effect is more stable.

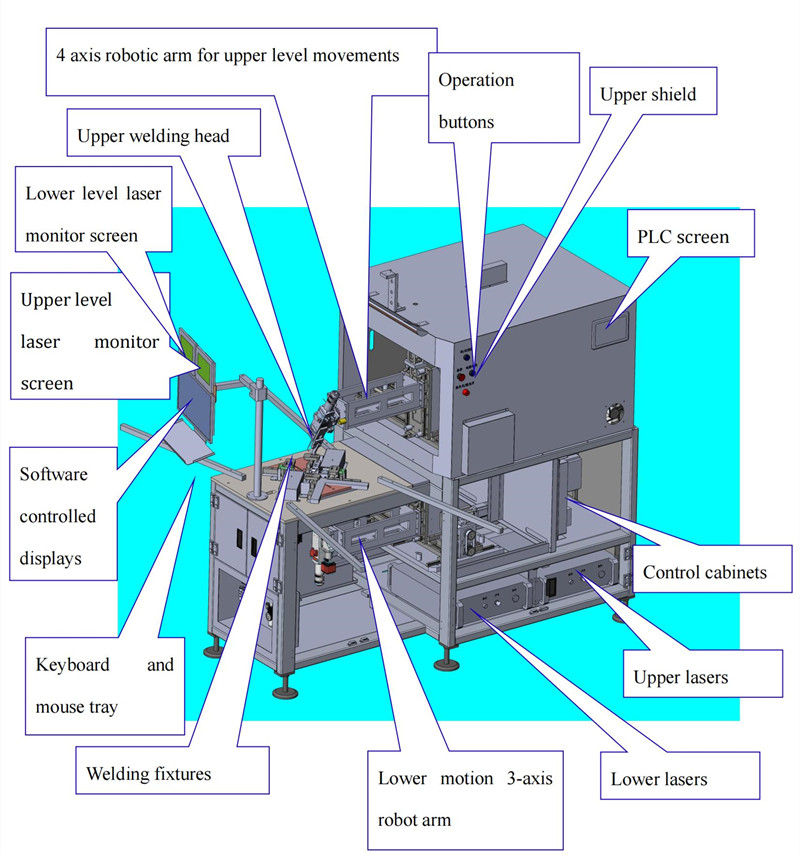

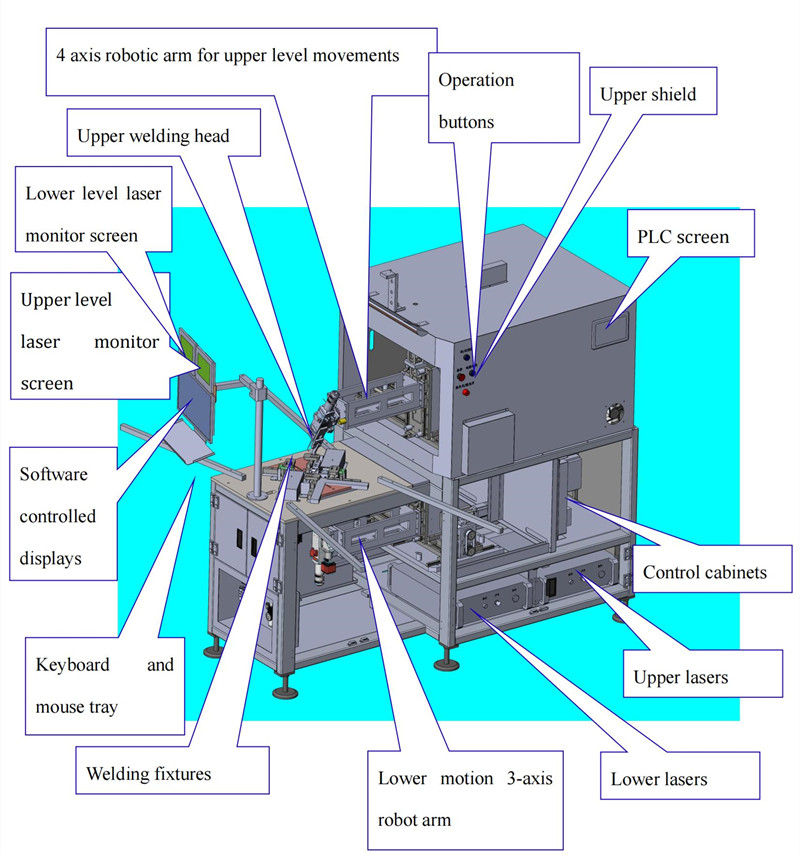

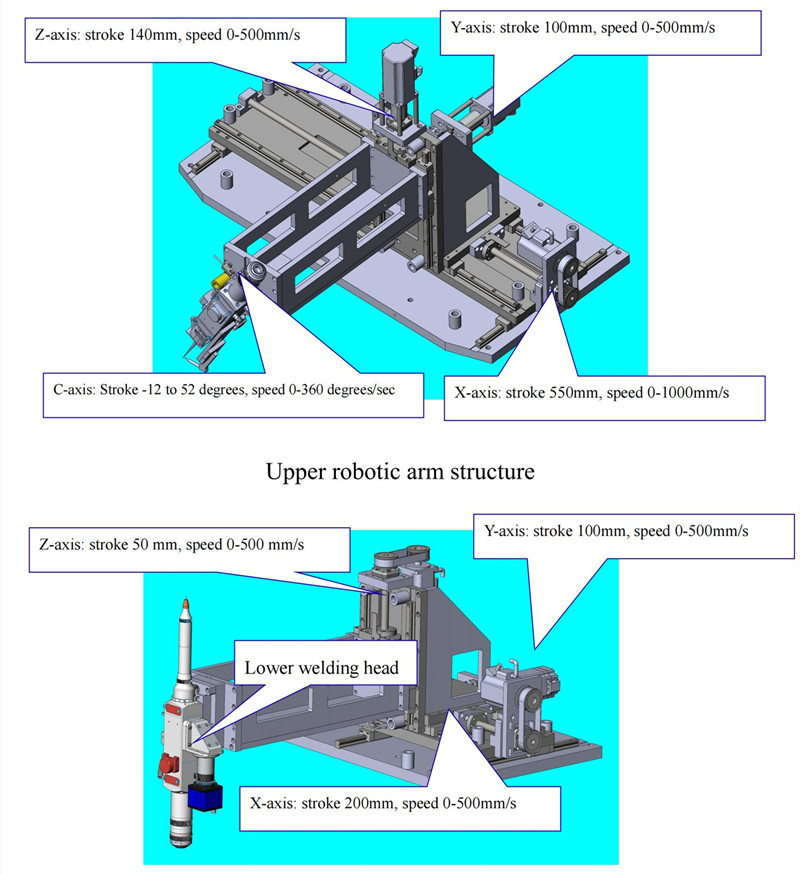

4.4-axis robotic arms are used on the upper level of the machine,which can weld both flat and vertical corners of the product to meet the diversity of product welding requirements.

5.The lower layer of the machine is equipped with a 3-axis robotic arm,which can weld the multi-layer plane of the product: the robot on the upper and lower machine layers moves simultaneously, resulting in high welding efficiency.

6. The equipment allows the use of clean compressed air for optical lens protection without the addition of welding wire, reducing the production costs of using argon gas.

7. Can be welded to 45 degree angle light frame products with specifications ranging from 200*200 to 1200*1200.

Introduction to the equipment structure

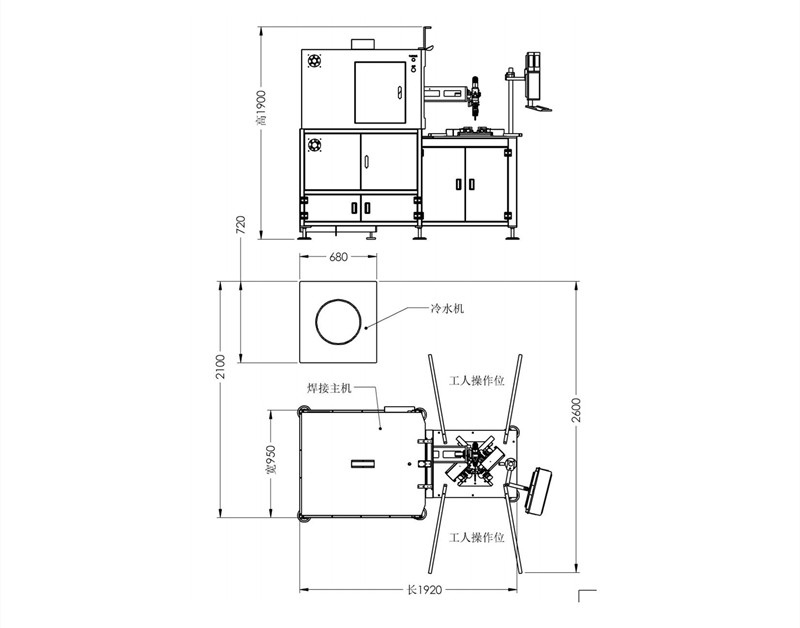

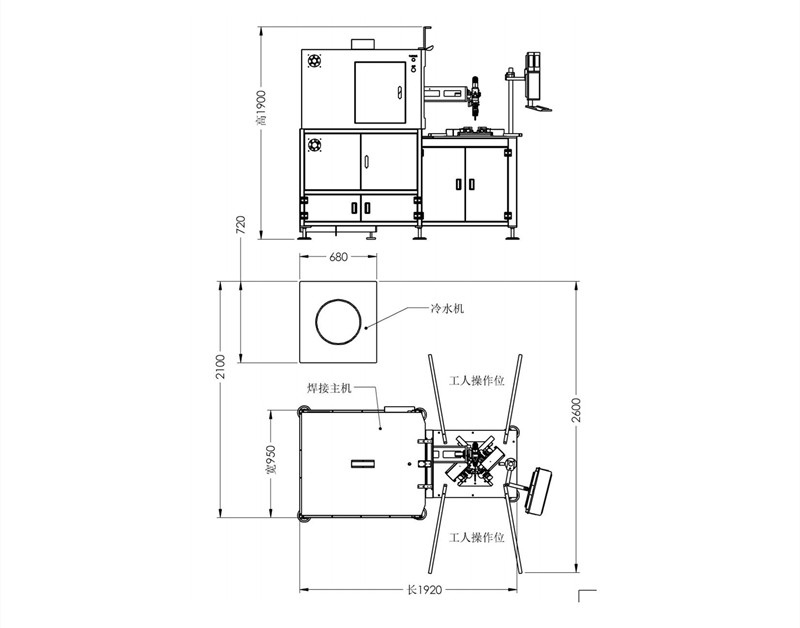

External dimensions of the equipment

Main body: Length 1920mm * Width 950mm * Height 1900mm,Chiller specifications: 720mm*680mm*970mm (this size is for reference only, as the choice of laser power is not the same, the chiller appearance size will be different).

Technical parameters of the equipment

1. Equipment model: ZM-JGHS-7-R

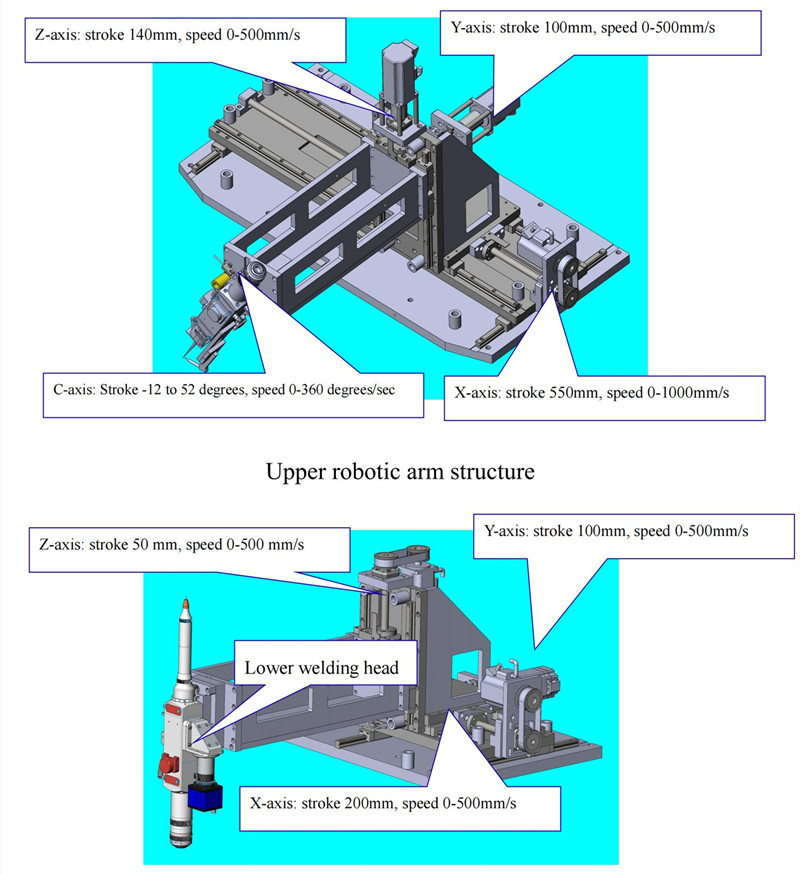

2. Upper 4-axis robot arm travel: X-axis 550mm; Y-axis 100mm; Z-axis 140mm;C-axis -12 to 52 degrees.

3. Lower 3-axis robot arm travel: X-axis 200mm; Y-axis 100mm; Z-axis 50mm.

4. Robotic arm speed: X-axis 0-1000mm/S; Y-axis 0-500mm/S.Z-axis 500mm; C-axis 0-360 degrees/S.

5. Repeat positioning accuracy of robot arm: XYZ ±0.02mm, C-axis ±0.01 degree.

6. Equipment air pressure: 0.5~0.8Mp

7.Equipment power supply: 220V±10% 50HZ

8. Equipment working environment: temperature 10~35°C temperature 10~80%

9. Equipment output peak power: 18.0KW

10. Laser peak output power: 1500W*2 or 1000W*2

11. The equipment is additionally equipped with a water chiller of the same power for cooling the laser and welding head.

Laser welding machine for aluminium frames, Aluminum Door Window Frame, Welded Aluminum Frames,aluminium frames,frame aluminium profile,aluminum dock frame,Aluminum Frame, Metal Frame, Picture Frame, Photo Poster Frame, Full Length Mirror, Floor Mirror, Standing Mirror, Full Body Mirror, Large Mirror, Floor Length Mirror, Wall Mirror, Gold Mirror, Gold Aluminum Frame. Full Length Mirror, Floor Mirror, Standing Mirror, Full Body Mirror, Large Mirror, Floor Length Mirror, Wall Mirror, Gold Mirror Aluminum Frame.