Part Leveling Machines for Light Laser and Stamped Parts

These part leveling machines are designed specifically for light laser-cut, plasma-cut, and stamped parts, offering precise leveling and improved surface flatness. Below are the key specifications and the features that make them ideal for applications requiring high precision and efficiency:

Key Specifications:

Width: 200-2200mm

Roll Diameter: 30mm

Rated Thickness: 0.5-2.5mm

Number of Rolls: 21 (Upper: 10, Lower: 11)

Leveling Roller Gap Adjustment Method: Four-point automatic adjustment, driven by servo motors

| Model | STR-20CNC | STR-30CNC | STR-40CNC | STR-50CNC |

| Width (mm) | 200-1300 | 200-2200 | 400-2200 | 400-2200 |

| Roll Diameter (mm) | 20 | 30 | 40 | 50 |

| Rated Thickness (mm) | 0.2-1.5 | 0.5-2.5 | 0.6-3 | 0.8-4 |

| Maximum Thickness (mm) | 1.5 | 2.5 | 3 | 4 |

| Number of Rolls | 23 (Upper: 11, Lower: 12) | 21 (Upper: 10, Lower: 11) | 21 (Upper: 10, Lower: 11) | 21 (Upper: 10, Lower: 11) |

| Shortest Part (mm) | 10x40 | 10x60 | 10x75 | 15x100 |

| Leveling Speed (m/min) | 0-12 | 0-12 | 0-12 | 0-12 |

| Leveling Roller Gap Adjustment | Four-point auto, driven by servo motors | Four-point auto, driven by servo motors | Four-point auto, driven by servo motors | Four-point auto, driven by servo motors |

| Voltage | 3-phase 380V | 3-phase 380V | 3-phase 380V | 3-phase 380V |

Key Features:

Precision Leveling:

These machines are equipped with 21 rolls (10 upper, 11 lower), providing exceptional leveling performance. The servo-driven four-point auto adjustment ensures accurate and consistent leveling, even for parts with varying thicknesses and geometries.

Versatile Processing Range:

Suitable for a wide range of laser-cut, plasma-cut, and stamped parts with a thickness range of 0.5 to 2.5mm, these machines can handle light sheet metals with working widths from 200mm to 1300mm, making them ideal for smaller to medium-sized workpieces.

Automatic Gap Adjustment:

The automatic gap adjustment, controlled by servo motors, ensures precision leveling, compensating for variations in material thickness. This feature reduces the need for manual intervention, improving efficiency and consistency in the leveling process.

Efficient Operation:

With servo-controlled adjustments and a high number of leveling rolls, these machines enable rapid leveling of parts, resulting in improved flatness and minimal distortion. This enhances the quality of finished products and reduces rework or defects in subsequent processing steps.

High Throughput:

Designed to handle high volumes of production, these machines ensure efficient material flow and consistent performance even under demanding industrial environments, making them perfect for laser job shops, metal fabricators, and light metal parts manufacturers.

Applications:

This Part Leveling Machine is ideal for industries that require precise flatness and dimensional accuracy in their light metal parts, particularly in the following applications:

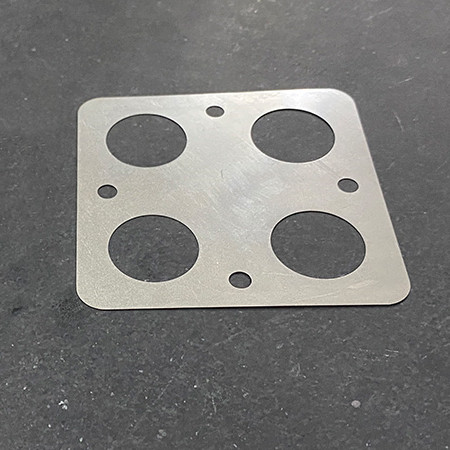

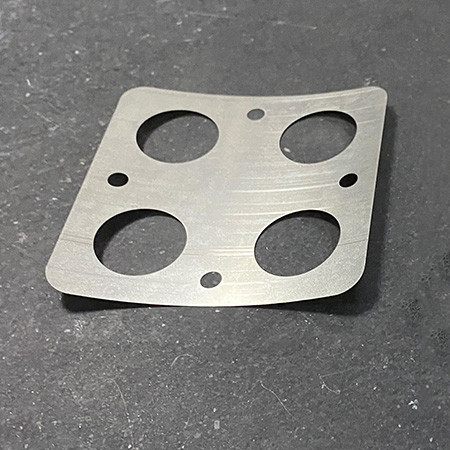

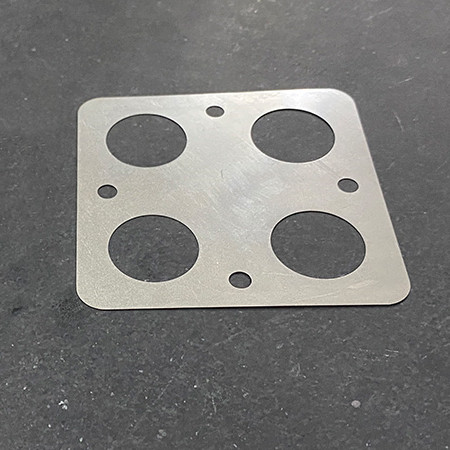

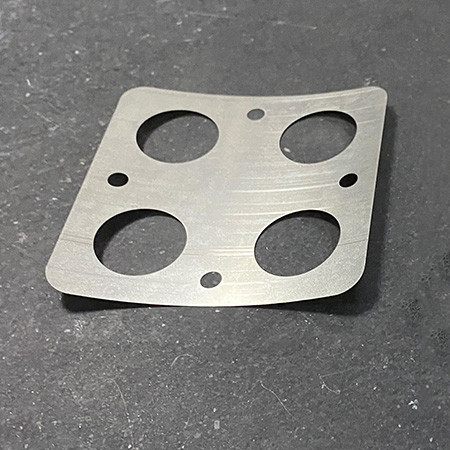

Laser-cut parts: Parts that have been cut using laser technology, which often require post-processing to remove warping or distortion.

Plasma-cut parts: Plasma-cut metal sheets that benefit from leveling to achieve consistent thickness and flatness.

Stamped parts: Stamped metal components that need to be flattened before further processing, such as welding, bending, or painting.

Industries that benefit from this machine include:

Benefits:

Improved Flatness: Consistent flatness across all parts, reducing the need for secondary processing or quality control.

Increased Productivity: High-level automation reduces downtime and manual labor.

Cost Efficiency: Lower operational costs due to high throughput, reduced rework, and minimal waste.

Enhanced Quality: Perfect for high-precision applications where dimensional accuracy and smooth surfaces are required.