Precision Leveling for Thin Metal Parts:

This machine is tailored for leveling light-gauge parts with thicknesses ranging from 0.2mm to 1.5mm, which is ideal for industries that work with thin materials such as sheet metal for electronics, automotive components, or appliance manufacturing. It ensures flatness, removing any distortions caused by the cutting or stamping processes.

Automatic Four-Point Gap Adjustment:

The four-point automatic gap adjustment system uses servo motors to automatically adjust the gap between the upper and lower rollers based on the material's thickness. This ensures consistent pressure distribution across the sheet, leading to uniform leveling without manual intervention, which improves accuracy and productivity.

Optimized for Light Metal Sheets:

The machine is equipped with 20mm diameter rolls that provide precise leveling for thin and light metal sheets. This size is optimal for handling delicate materials without damaging them, making it ideal for processing laser-cut or stamped metal parts that are prone to warping due to the heat or pressure of the cutting process.

Wide Range of Applications:

With a working width of 200-1300mm, this machine can handle a wide variety of light metal sheets and parts, making it suitable for small- to medium-sized parts. The machine’s flexibility in width allows it to process different part sizes in automotive manufacturing, appliance production, and metalworking.

Efficient and Consistent Results:

The servo-driven automatic gap adjustment ensures that the machine adjusts dynamically to varying material thicknesses. This automatic adjustment minimizes the need for manual reconfiguration, making the leveling process faster and more consistent, with reduced downtime between different jobs.

Number of Rolls:

The machine features 23 leveling rolls (11 upper and 12 lower), which ensures optimal pressure distribution across the material. This configuration is especially effective for lightweight metal parts that require high precision to ensure the part's flatness without overworking the material.

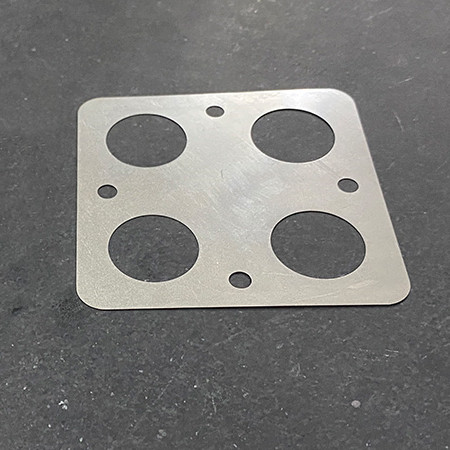

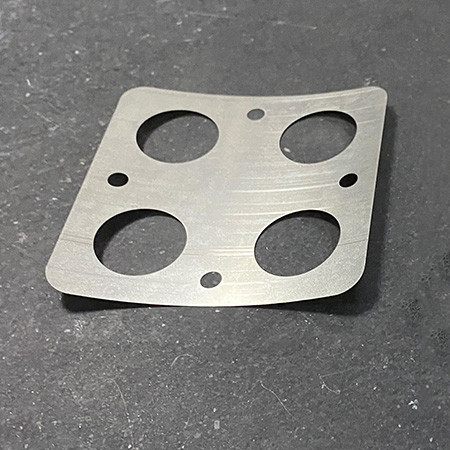

Laser-Cut Parts:

Laser cutting often results in slight distortion due to the high heat involved in the process. The leveling machine corrects any warping or curling in laser-cut parts, ensuring they are perfectly flat for further use in assembly or additional machining processes.

Plasma-Cut Parts:

Plasma cutting can cause heat-induced deformations, leading to parts that are not flat. This machine flattens plasma-cut parts to ensure they meet the required specifications for further processing, such as welding, coating, or assembly.

Stamped Parts:

Stamping can cause minor distortions in parts due to the high pressure applied during the stamping process. The leveling machine flattens stamped metal parts, ensuring they are ready for precision work, such as assembly or installation in machinery.

Thin Sheet Metal Fabrication:

This leveling machine is especially suited for light-gauge sheet metal fabrication, where thin metal sheets (ranging from 0.2mm to 1.5mm thick) need to be leveled after processes like cutting, punching, or stamping. It ensures that sheets are flat and dimensionally accurate, which is crucial for parts used in electronics, appliances, or other precision applications.

Electronics Industry:

In the electronics industry, thin metal sheets are often used for enclosures, brackets, and other components. This leveling machine is ideal for leveling laser-cut or stamped sheets used in electronics manufacturing, ensuring a smooth surface for further processing or assembly.

Automotive Components:

Automotive manufacturers rely on high-precision metal parts that are flat and accurate. The machine can level light gauge parts used in the automotive industry, including body panels, brackets, and small components, which require precise flatness and dimensional accuracy.

Appliance Manufacturing:

Appliance manufacturing involves the use of thin metal sheets for producing parts like casing, panels, or structural components. This machine can process these materials to ensure they are level and ready for final assembly or coating.

Increased Precision: The automatic four-point gap adjustment ensures that parts are leveled accurately to meet strict tolerances.

Improved Efficiency: With automatic adjustments based on material thickness, the leveling process is faster, reducing production times and increasing throughput.

Reduced Labor Costs: The machine’s automatic systems minimize the need for manual setup and intervention, resulting in lower labor costs.

Consistent Results: The servo-driven automatic adjustments ensure that the leveling process is consistent across different materials, reducing variations in product quality.

Versatility: With its ability to handle a wide variety of part sizes and materials, this leveling machine is a flexible solution for different industries and applications.

Enhanced Product Quality: Leveling ensures that metal sheets and parts are flat and dimensionally accurate, which improves the overall quality and performance of the final product.