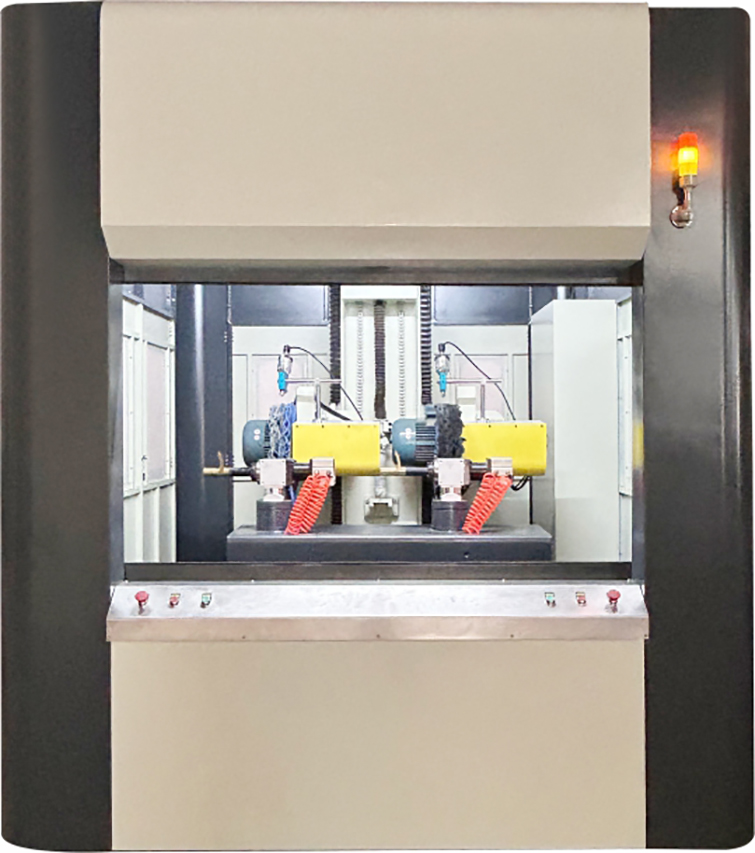

CNC Polishing Machine for Kitchen Handles and Furniture Parts: High-Quality Mirror Finishing (Dual-Station Polishing Machine)

Overview:

A CNC Polishing Machine designed to polish kitchen handles and furniture parts, providing a high-quality mirror finish. This dual-station machine enables simultaneous polishing of multiple parts, maximizing efficiency while maintaining superior consistency and surface quality. Ideal for manufacturers requiring precision and productivity in polishing metal components.

Key Features:

Dual-Station Design:

High-Precision CNC Control:

Fully automated and programmable paths for consistent, high-quality finishing.

Customizable settings for speed, pressure, and polishing cycles.

Mirror Finishing Capability:

Achieves a smooth, reflective surface free of scratches and blemishes.

Suitable for decorative and functional components requiring a premium finish.

Versatile Application:

Capable of polishing straight, curved, and intricate shapes.

Handles diverse materials such as aluminum, stainless steel, and brass.

Heavy-Duty Construction:

Eco-Friendly Operation:

Applications:

Kitchen Handles:

Polishing cabinet handles, drawer pulls, and other kitchen fittings.

Ensures smooth edges and a premium finish for modern kitchen designs.

Furniture Parts:

Buffing decorative metal elements like knobs, pulls, and trim.

Ideal for luxury furniture requiring a flawless aesthetic.

Other Products:

Process Workflow:

Loading:

Deburring:

Grinding:

Polishing:

Inspection:

Advantages of the Dual-Station CNC Polishing Machine:

Enhanced Productivity:

Superior Quality:

Cost-Efficient:

Operator-Friendly:

Wide Compatibility:

Technical Specifications (Example Configuration):

Polishing Stations: Dual independent workstations.

Material Capability: Aluminum, stainless steel, brass.

Surface Finish: Mirror-like polish with adjustable roughness.

Control System: High-precision CNC with HMI interface.

Tooling Options: Customizable polishing pads, brushes, and abrasives.

Dust Collection: Integrated system with high-efficiency filtration.