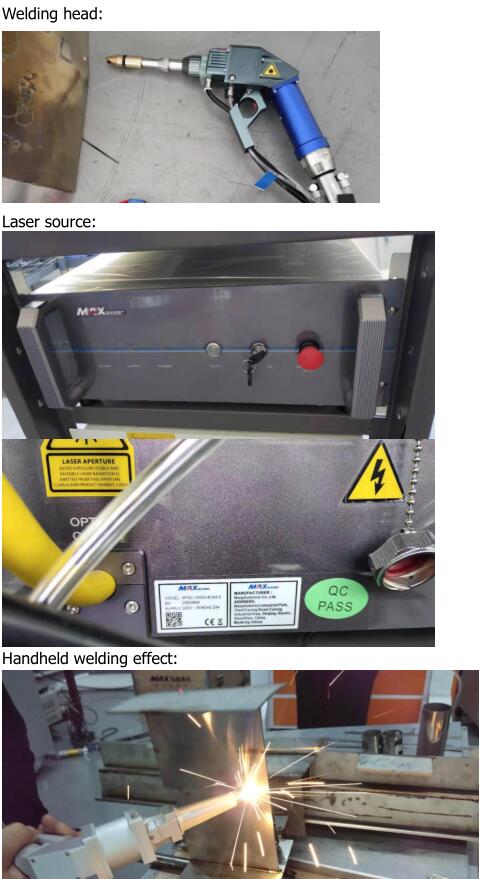

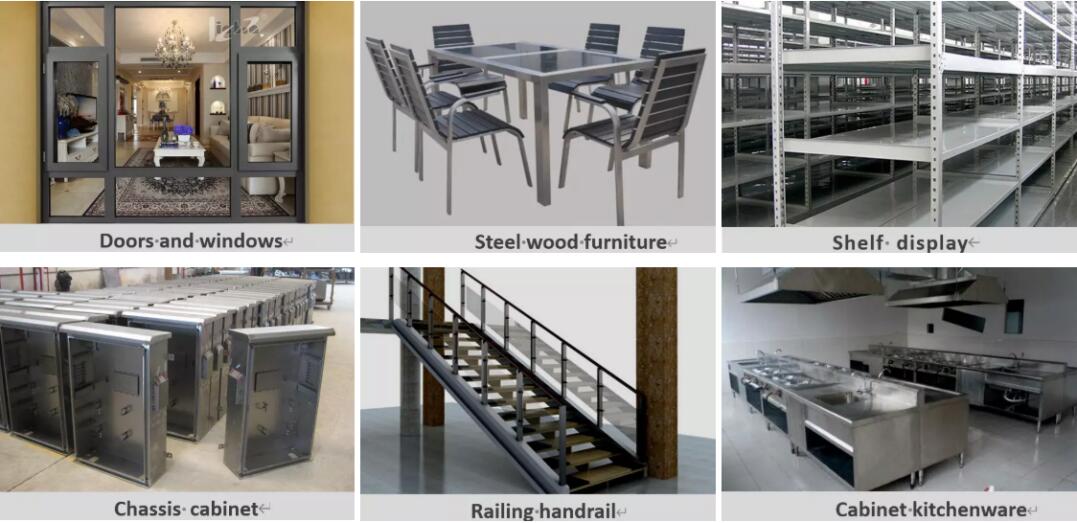

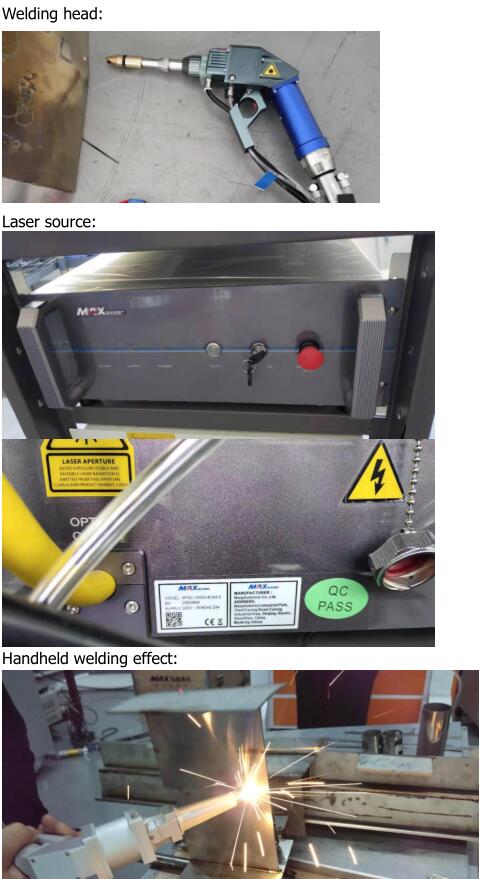

Laser welding is a kind of processing method of welding materials with high energy density laser beam as heat source. It has the advantages of simple operation, beautiful weld seam, fast welding speed and no consumables.

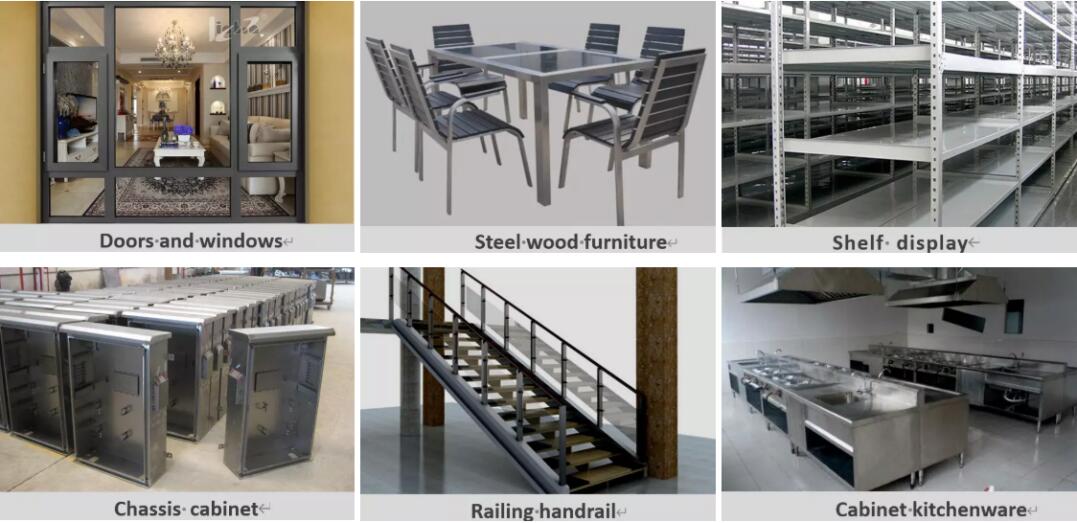

In recent years, due to the continuous development of materials, technology and technology, laser welding has been widely used in the welding of plastics, metals, etc. in automobiles, sensors, electronics, stainless steel processing, cabinet kitchens, stair elevators, shelves, ovens, stainless steel. Door and window guardrails, distribution boxes and other industries will continue to replace traditional welding methods such as argon arc welding.

Advantage of handheld laser welding?

★ Low consumables and long life.

★ Fast welding speed , 2-3 times faster than the traditional welding.

★ Simple operation, no need to hire professional welding personnel, reduce investment costs.

★ High safety, with multiple safety alarms, automatically lock light after removing the workpiece.

★ The weld seam is smooth and beautiful, no deformation, reduce the subsequent grinding process, saving time and costs.

Handheld laser welding machine in customer workshop https://youtu.be/cGhemuw8Pe8