CNC sheet metal folding machines are advanced equipment used to bend and fold sheet metal into various shapes with high precision and repeatability. These machines are typically utilized in industries like automotive, aerospace, construction, electronics, and furniture manufacturing for producing parts that require complex bends and precise angles.

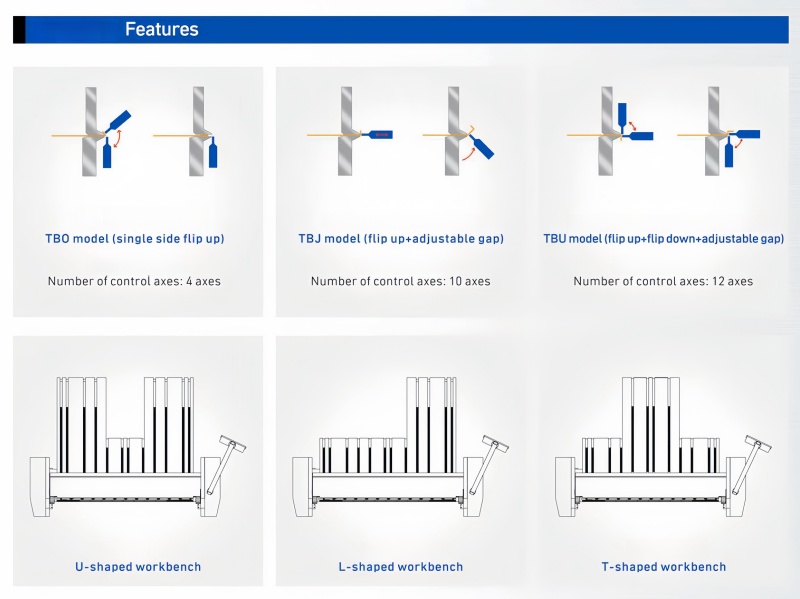

Sheet Metal Positioning: The metal sheet is placed onto the machine's worktable, where it is clamped in position.

CNC Programming: The folding machine is controlled by a CNC (Computer Numerical Control) system that uses pre-programmed commands to control the machine’s axes. This allows the machine to perform precise bending operations based on the program. Operators input the required specifications, such as bend angles, folding length, and part dimensions, into the machine's interface.

Bending Process: A folding beam or a press mechanism lifts and bends the metal sheet according to the programmed instructions. Multiple axes can control the movement of the sheet and the tooling, ensuring the correct angle and dimensions are achieved.

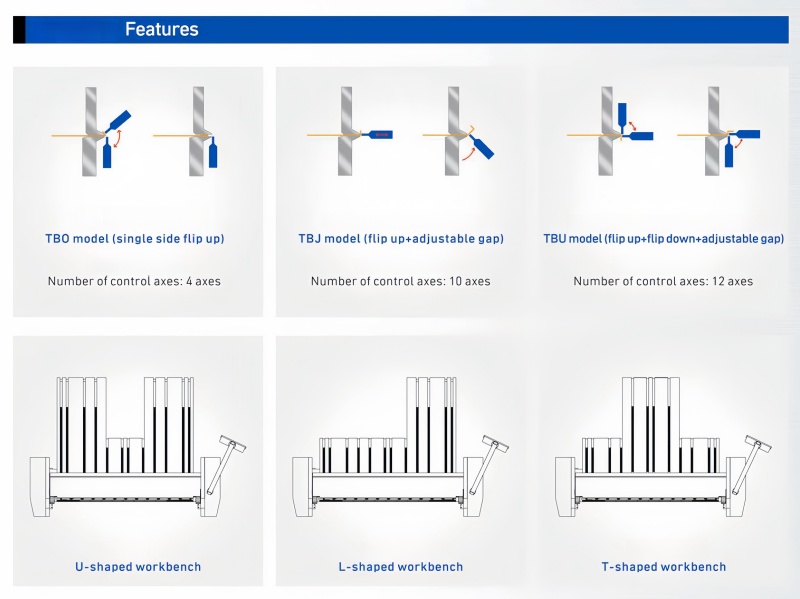

Axis Control: CNC folding machines typically control multiple axes (X, Y, Z) to ensure the correct alignment and bending of the sheet metal. Some machines also have additional axes (A, B) to handle more complex part geometries.

Automation and Precision: The CNC system calculates the force required to bend the material without exceeding its limits, ensuring consistent results with minimal human intervention.

Key Features of CNC Sheet Metal Folding Machines:

CNC Control:

Provides precise and automated bending operations.

Includes a graphical user interface (GUI) that allows operators to program different shapes, angles, and part dimensions.

Stores multiple programs for quick changeovers between production runs.

Multi-Axis Capability:

CNC folding machines are equipped with multiple axes to control the positioning and bending of the sheet metal. This allows for complex folding patterns and reduces the need for manual adjustments.

Commonly, machines have X, Y, Z axes, while more advanced models can feature up to 10 or more axes for intricate part design.

Material Versatility:

Can handle various types of materials including steel, stainless steel, aluminum, copper, and other alloys.

Typically supports thin to medium-thick sheets, with thicknesses ranging from 0.5mm to 2mm or more, depending on the machine's capacity.

Bending Length & Angle:

Can perform a wide range of bends, with bending lengths typically ranging from 2500mm to 4100mm or more.

Capable of folding at different angles, usually between 45° and 180°, depending on the application.

Motor Power:

Safety Features:

Many models come with safety systems like light curtains and emergency stop switches to protect operators during operation.

Additionally, they include automated clamping and unloading mechanisms to minimize operator contact with moving parts.

Types of CNC Sheet Metal Folding Machines:

Press Brake Folding Machines: These machines use a punch and die system to bend the sheet metal. The punch presses the metal into the die to create bends at desired angles. These are commonly used for high-precision bending tasks in large-scale production.

Folding Beam Machines: In this type of machine, a beam clamps the metal, and the folding beam moves up and down to create the bend. This is useful for larger sheet metal applications where precision and flexibility are required.

Electric Folding Machines: Electric CNC folding machines are highly energy-efficient and suitable for medium-duty applications. They use electric motors instead of hydraulic systems, resulting in smoother, quieter operations and higher precision.

Hydraulic CNC Folding Machines: These machines are designed for heavy-duty applications, offering more power for thicker and tougher materials. Hydraulic machines are commonly used when higher bending forces are required.

Applications of CNC Sheet Metal Folding Machines:

Automotive Industry: Used to manufacture various car parts, including chassis components, body panels, and structural reinforcements.

Aerospace Industry: The precision of CNC folding machines is ideal for producing aircraft parts, including fuselage sections, wing components, and interior fittings.

Electronics and Enclosures: CNC folding machines are used to create metal enclosures for electronic equipment, providing high precision and durability in the design of cases, frames, and housings.

Furniture Manufacturing: These machines can produce metal furniture frames, supports, and other components with accurate bends and smooth finishes.

Construction Materials: The machines are used to fabricate metal panels, roofing components, structural beams, and other parts required in construction.

Advantages of CNC Sheet Metal Folding Machines:

High Precision and Consistency: The CNC system ensures that each part is produced with the same accuracy, reducing errors and minimizing waste material.

Improved Efficiency: CNC folding machines automate the bending process, reducing production time and increasing throughput, especially for high-volume production runs.

Reduced Labor Costs: The automation provided by CNC machines reduces the need for manual labor, which lowers labor costs while maintaining high-quality production.

Flexibility: These machines can handle a wide variety of materials and are capable of producing complex shapes, making them ideal for customized and prototype work as well as mass production.

Environmentally Friendly: Many modern CNC folding machines are designed to be energy-efficient, using electric drives instead of hydraulic systems, leading to lower energy consumption and reduced environmental impact.

CNC Control System:

CPU: Intel Core i5.

Memory: 8GB.

Hard disk: 64GB SSD.

Key features: online and offline programming, backup, real-time status monitoring, Windows OS, and support for scanning codes.

Axis Configuration:

TBJ model: 10 axes.

A-axis travel: 0-88mm.

B-axis travel: 0-120mm.

Technical Parameters:

Includes various models such as TB025, TB032, TB041, and TBU32 with information like bending force, bending length, and axis speeds.

Technical Parameters

| Item | Unit | TB025 | TB032 | TB041 | TBU25 | TBU32 | TBU41 |

| Processing thickness | mm | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 |

| Processing thickness (stainless steel) | mm | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Bending length | mm | 2500 | 3200 | 4100 | 2500 | 3200 | 4100 |

| Bending angle | degrees | 45...180 | 45...180 | 45...180 | 45...180 | 45...180 | 45...180 |

| Speed | mm/s | 30 | 30 | 30 | 30 | 30 | 30 |

| X-axis travel | mm | 2500 | 3200 | 4100 | 2500 | 3200 | 4100 |

| Y-axis travel | mm | 100 | 100 | 100 | 100 | 100 | 100 |

| Z-axis travel | mm | 2500 | 3200 | 4100 | 2500 | 3200 | 4100 |

| Main motor power | kW | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 |

| Dimensions (L x W x H) | mm | 3100x1800x3100 | 3700x1800x3100 | 4500x1800x3100 | 3100x1800x3100 | 3700x1800x3100 | 4500x1800x3100 |

| Weight | kg | 3500 | 4500 | 7500 | 4000 | 6000 | 8000 |

This table shows key specifications such as processing thickness, bending length, bending angle, speed, axis travel ranges, motor power, dimensions, and weight for different CNC folding machine models.