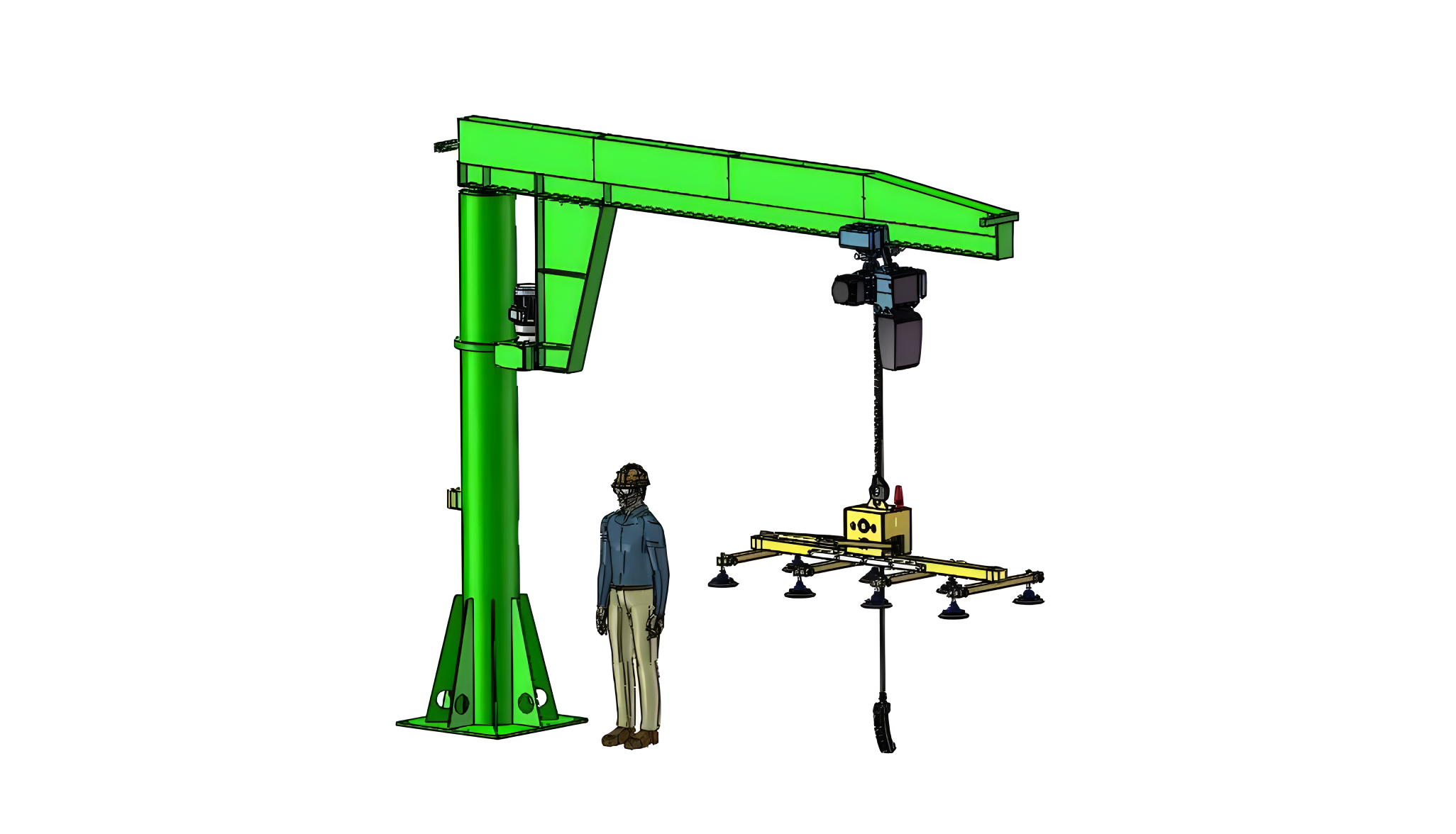

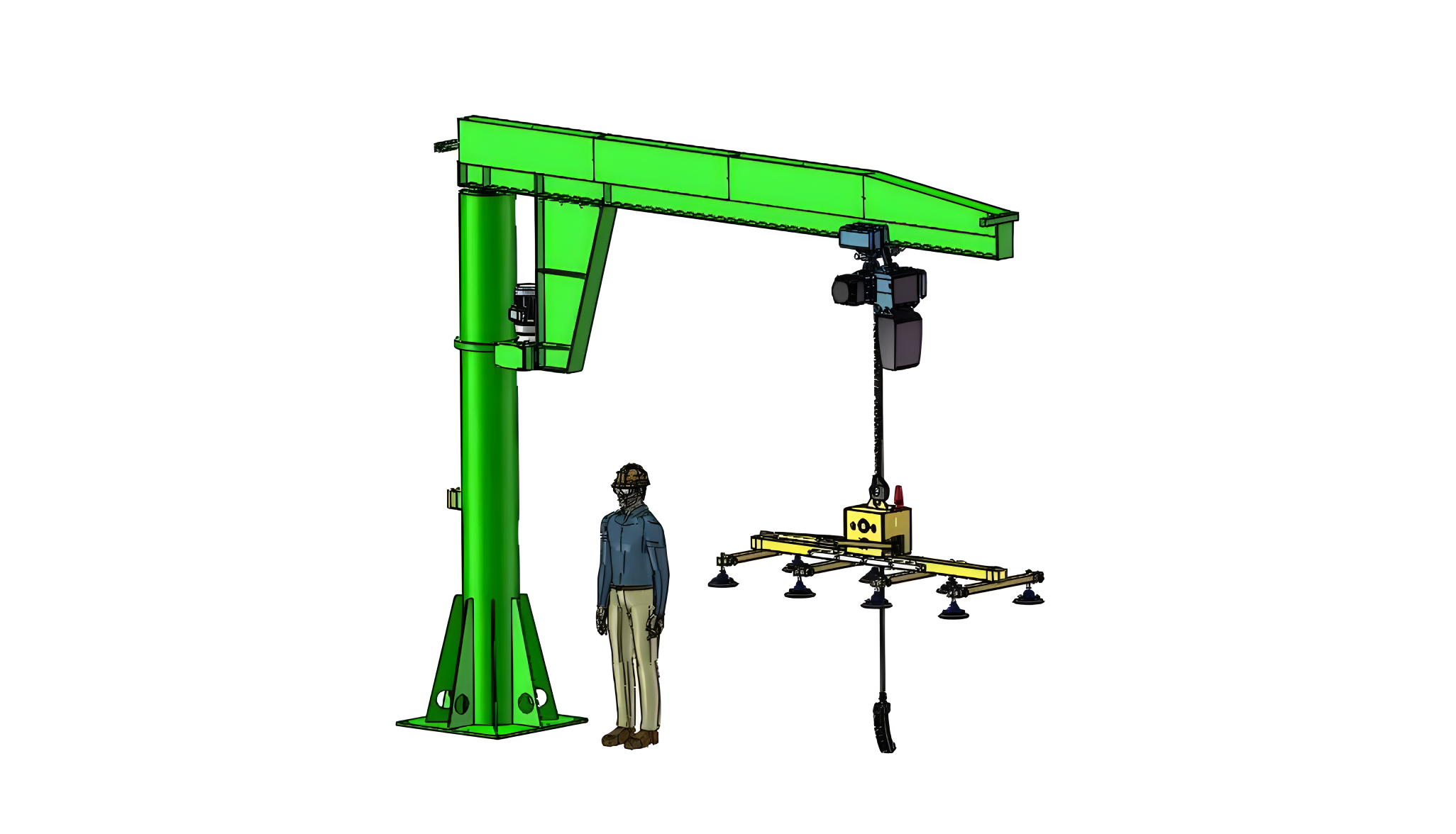

DC12V battery-powered vacuum lifters are ideal for handling large, heavy materials like glass composite panels, metal plates, and other large flat materials. These lifters use a battery-powered vacuum pump to generate the suction needed for lifting and transporting materials safely and efficiently. They are typically used in industries such as construction, metal processing, and glass manufacturing. The ability to lift up to 800kg makes them suitable for handling heavy and bulky items without requiring manual effort.

Features and Benefits:

DC12V Battery-Powered: Operates on a 12V battery, providing mobility and reducing the need for a direct power source.

High Load Capacity: Can handle up to 800kg of weight, making it ideal for large, heavy materials.

Vacuum Suction Technology: Ensures a secure grip on materials with a powerful vacuum suction system, reducing the risk of accidents or damage during transport.

Versatile Applications: Can be used for handling glass, metal plates, composite panels, and other large flat materials.

Portability: Battery-powered and compact, the lifter can be moved easily across various work areas.

Safety Features: Equipped with safety mechanisms like an emergency release valve and vacuum gauge to ensure stability during operation.

Common Applications:

Glass Handling: Transporting large glass panels without risk of breakage.

Metal Plates: Lifting and moving heavy metal sheets with ease.

Composite Panels: Safe handling of composite materials commonly used in construction and automotive industries.

Pneumatic Vacuum Lifter

| Product Model | JS-300-2M/3M |

| Rated Load (kg) | 300 |

| Suction Cup Diameter (mm) | 150 |

| Number of Suction Cups | 8 |

| Outer Dimensions (mm) | 2000×1000, 3000×1000, 3000×1500, 4000×2000 |

| Plate Dimensions (mm) | 3000×1500, 4000×2000 |

| Working Voltage | 0.8 MPa Air Supply |

Battery-Powered Vacuum Lifter

| Product Model | JS-JG300-2M/3M | JS-JG600-2M/3M | JS-JG800-2M/3M |

| Rated Load (kg) | 300 | 600 | 800 |

| Suction Cup Diameter (mm) | 150 | 150 | 150 |

| Number of Suction Cups | 8 | 6 | 6 |

| Outer Dimensions (mm) | 2000×1000, 3000×1000, 3000×1500, 4000×2000 | Same as JS-JG300-2M/3M | Same as JS-JG300-2M/3M |

| Plate Dimensions (mm) | 3000×1500, 4000×2000 | Same as JS-JG300-2M/3M | Same as JS-JG300-2M/3M |

| Working Voltage | DC12V | DC12V | DC12V |

Plug-In Vacuum Lifter

| Product Model | JS-GC300-2M/3M | JS-GC600-2M/3M | JS-GC800-2M/3M |

| Rated Load (kg) | 300 | 600 | 800 |

| Suction Cup Diameter (mm) | 150 | 200 | 200 |

| Number of Suction Cups | 8 | 8 | 8 |

| Outer Dimensions (mm) | 2000×1000, 3000×1000, 3000×1500, 4000×2000 | Same as JS-GC300-2M/3M | Same as JS-GC300-2M/3M |

| Plate Dimensions (mm) | 3000×1500, 4000×2000 | Same as JS-GC300-2M/3M | Same as JS-GC300-2M/3M |

| Working Voltage | AC220V/380V | AC220V/380V | AC220V/380V |

Typical Equipment Applications:

Sheet Metal Processing Industry: Primarily used for loading and unloading sheets in laser cutting, stamping, bending, and other processes.

Metal Processing Plants: Suitable for bulk handling and stacking of metal sheets, especially during long-term, high-frequency operations, where automated equipment can effectively reduce errors and waste.

Home Appliance Manufacturing: Automated handling equipment can be used for transporting materials like refrigerator, washing machine, and air conditioner shells, enhancing the level of automation in production lines.

Automotive Manufacturing: In the processing of automotive body panels, automatic stacking and handling equipment ensures the safe transport of large sheet metal parts.

These devices provide an efficient automated solution for sheet metal processing, significantly reducing labor intensity while improving production efficiency and product quality.