product description:

DAPENG Laser F3015BG laser pipe cutting machine also exists as a sheet metal laser cutting machine at the same time. DAPENG Laser F3015BG is equipped with a pipe cutting device on the basis of metal laser cutting machine, thus becoming a laser pipe cutting machine, which can cut sheet metal and The function of cutting pipes is a more complete fiber laser cutting machine.

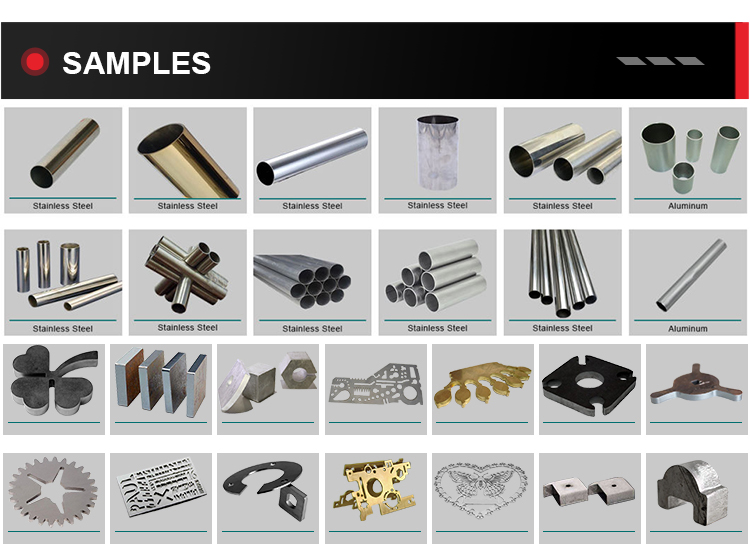

Applicable materials:

Laser power 1000W-800W (optional), tube laser cutting is used for various types of tubes such as square tube, round tube, rectangular tube, oval tube, D-shaped tube and hexagonal tube, 0.5-20mm carbon steel for plate cutting, 0.5 - 12mm stainless steel plate, galvanized plate, electrolytic plate, 0.5-10mm aluminum alloy plate cutting, 0.5-10mm brass and copper and other metal materials.

Features:

1. One machine for two purposes, can cut plates and pipes at the same time;

2. Equipped with a laser, the cutting efficiency is higher and the service life is longer;

3. The new-generation bed has a service life of more than 20 years;

4. The third-generation aviation aluminum beam reduces the weight on the premise of ensuring strength;

5. The weight of the whole machine is lower, and the gantry runs faster;

6. Automatic focusing laser head, electric clamping chuck, high configuration and high cost performance.

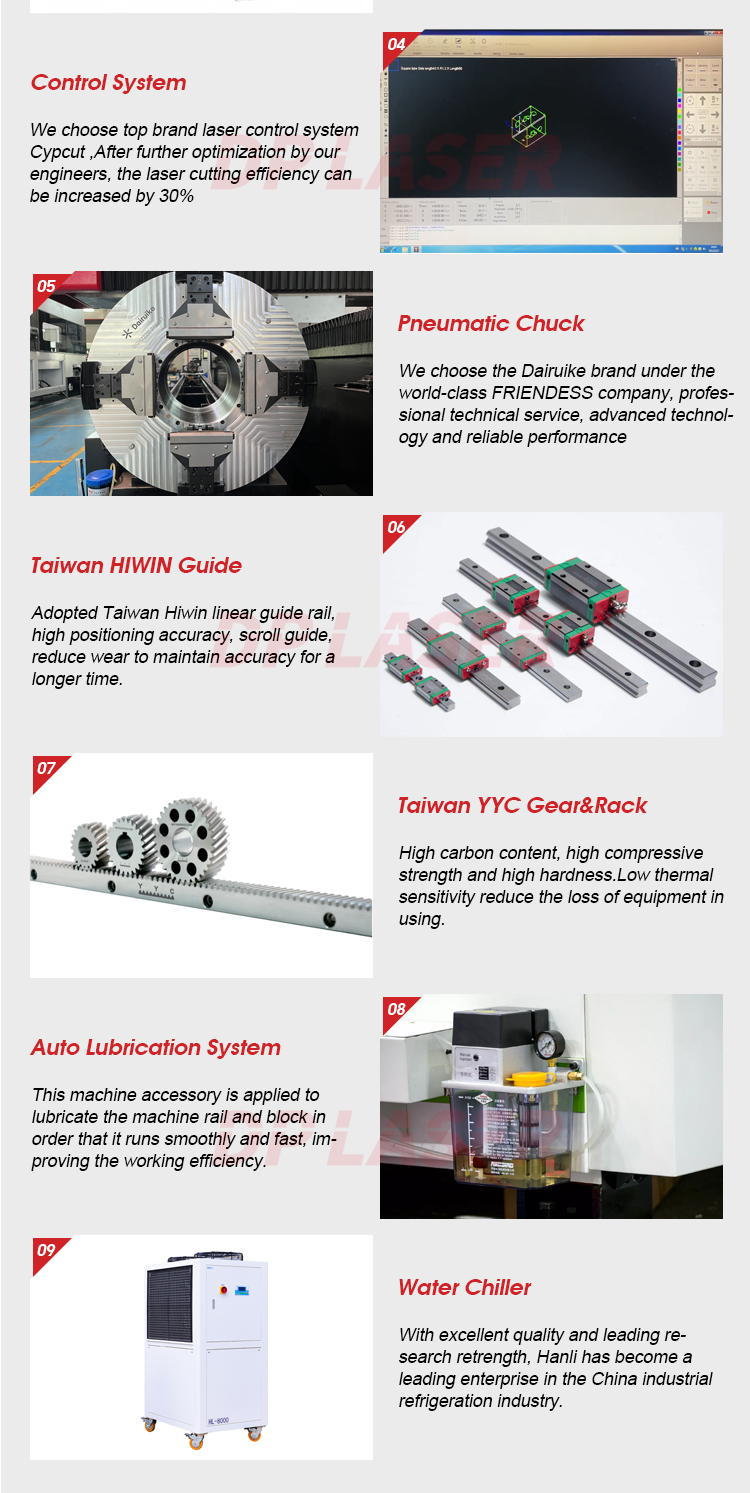

Product advantages:

1. The third generation aviation aluminum alloy gantry

Aerospace aluminum is manufactured according to aerospace standards and extruded with a 4,300-ton press. After aging treatment, the hardness can reach T6, which is the stronger hardness of all beams. Aviation aluminum has good toughness, light weight, corrosion resistance, oxidation resistance, low density, and greatly improves the processing speed.

2. One machine for two purposes, saving costs

It can cut both metal sheets and metal pipes. One machine can be used for multiple purposes. It saves the cost of purchasing two machines, saves space by more than half, and brings higher production efficiency.

3. Clamping design

The front and rear are clamped by electric chucks, the center is automatically adjusted, and the operation is simple. The diagonal adjustment range is 20~200MM.

4. Segmented automatic support device

The intelligent pipe support design solves the deformation problem during the cutting operation of long pipes.

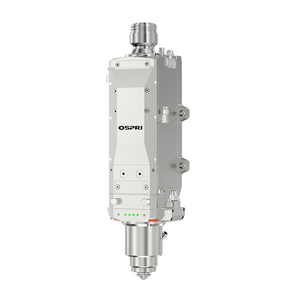

5. No manual operation, simple auto focus (make focusing easier)

(1) Automatic adjustment: There is no need for manual manual focus adjustment. The software automatically adjusts the focusing mirror and controls the upper and lower heights, so as to realize automatic perforation and cutting of plates of different thicknesses.

(2) Large adjustment range: +10~-10, precision 0.01mm, suitable for different types of 0~20mm plates.

(3) Long life: The collimating lens and focusing lens are double water-cooled, which reduces the temperature of the cutting head and improves the life of the cutting head.

6. Segmented rectangular tube welding bed

The internal structure of the bed adopts an aircraft metal honeycomb structure, which is welded by a plurality of rectangular tubes. Reinforcing ribs are arranged inside the tubes to increase the strength and tensile strength of the bed, increase the tensile strength and stability of the guide rail surface, and effectively avoid the deformation of the bed. . High strength, stability, tensile strength, guarantee 20 years of use without deformation; the wall thickness of the rectangular pipe is 10 mm, and the whole body weighs 4500 kg.

7. Transmission and precision

Equipped with Germany Atlanta rack, Japan Yaskawa Electric, Germany Newcastle reducer. The machine has a positioning accuracy of 0.02 and a cutting acceleration of 1.5g. Working life up to 10 years.

Industry application:

Due to the integrated design of plate and tube, the industry adaptability of LF3015CNR has been greatly enhanced, including the machining of oil pipes, fitness equipment and other pipe materials, and the machining of automobile manufacturing, chassis cabinets and other sheet materials.