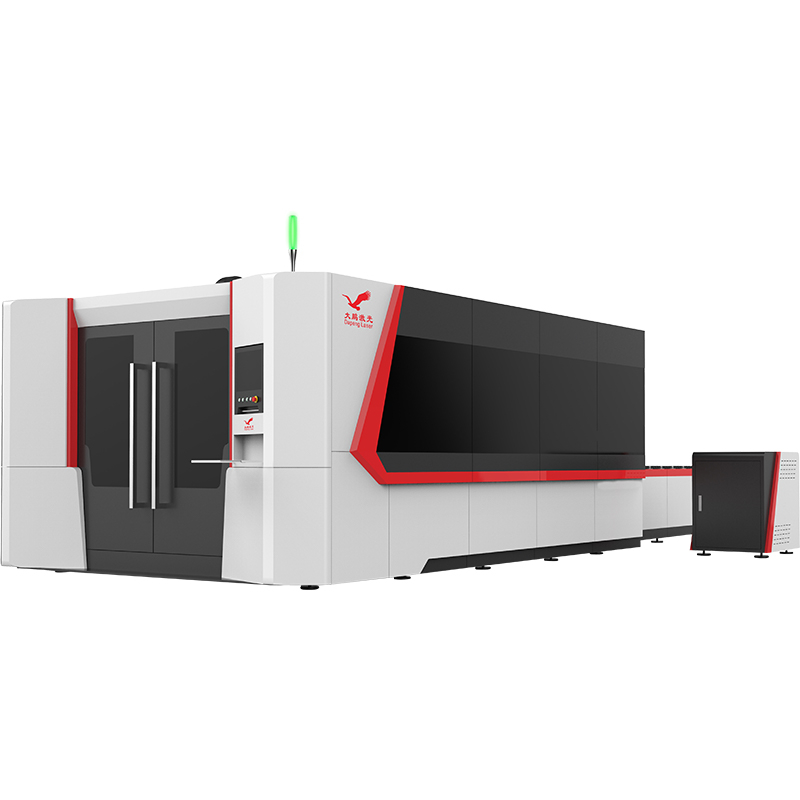

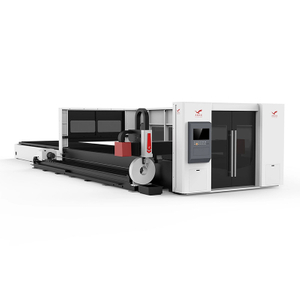

Full Enclosed 3015 4015 4020 6015 6020 6025 8025 10025 12025 IPG Raycus MAX nLIGHT CNC Metal Plate Fiber Laser Cutting Machine

The main technical indicators of Dapeng 6020 large metal fiber laser cutting machine are as follows

1 Processing format (length × width): 6000mm × 2000mm

2 X-axis travel: 6050mm

3 Y-axis travel: 2025mm

4 Z-axis travel: 110mm

5 X/Y axis positioning accuracy: 0.02mm/m

6 Repeated positioning accuracy of X/Y axis: +0.02mm

7 Maximum speed: 110m/min

8 Maximum acceleration: 1.0G

9 Machine weight: 4800Kg

10 CNC system: CYPCUT

11 Workbench Load: 800kg

12 Phases: 3

13 Rated voltage of power supply: 380V

14 Frequency: 50Hz

15 Overall power protection level: IP54

Features of Dapeng 6020 large metal fiber laser cutting machine:

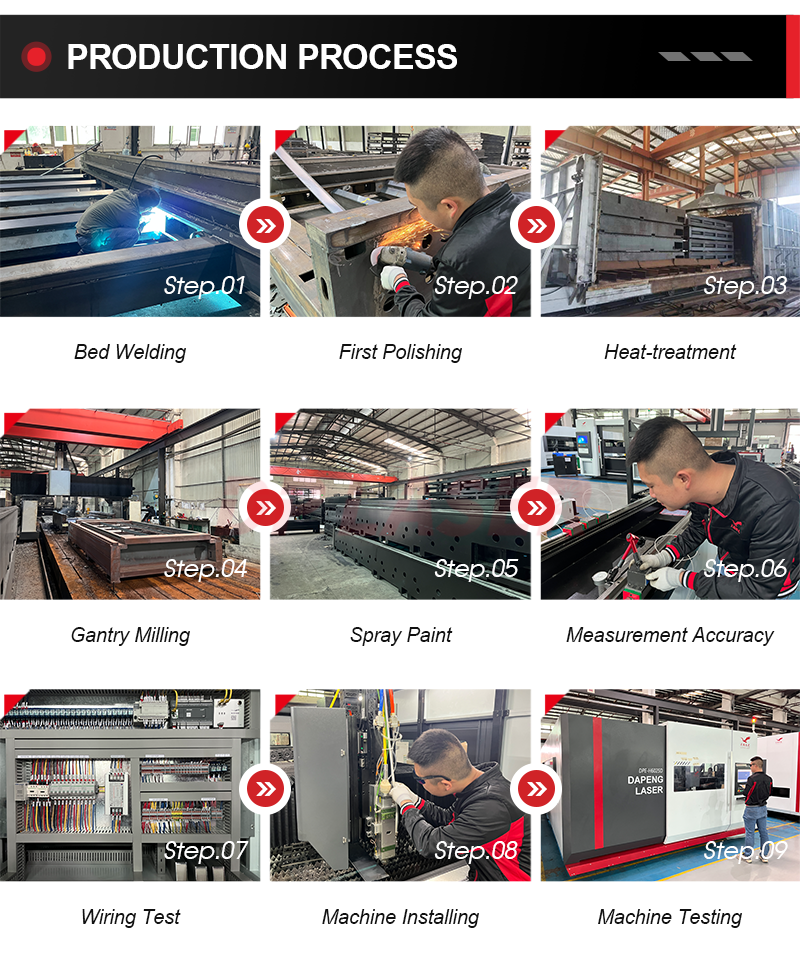

1. The machine adopts an open table structure, high-precision double-drive rack and pinion and linear guide rails, with stable transmission and high precision.

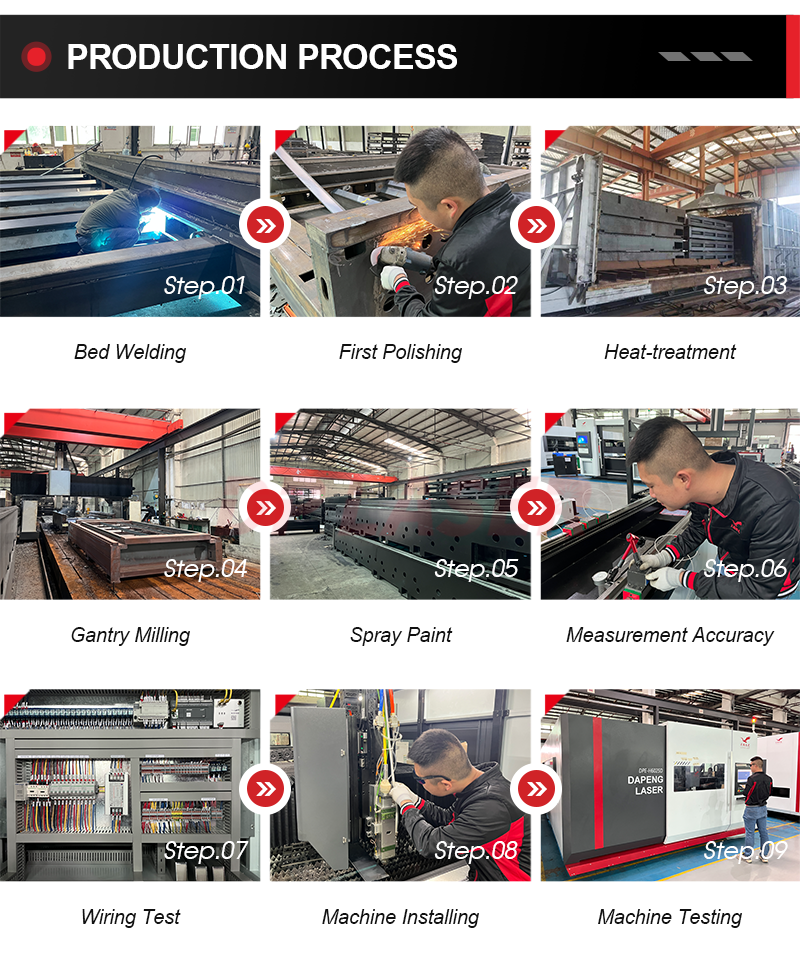

2. Both the bed and the moving beam adopt an integral welded structure. The bed is heat treated at a high temperature of 600°C, finished by 12-meter gantry milling, cooled with the furnace for 24 hours, roughed after annealing, and then subjected to vibration aging treatment, which can completely eliminate welding and welding. Processing adaptability, good rigidity, high precision, and can be maintained for a long time without deformation.

4. X, Y and Z axes all use French advanced servo motors, with high precision, high speed, large torque, large inertia, and stable and durable performance. It ensures the high speed and acceleration of the whole machine.

5. It adopts the CNC system of CYPCUT fiber laser cutting machine based on Windows operating system, and integrates many laser cutting control function modules, with powerful functions, good man-machine interface and simple operation.

6. CYPNEST expert nesting software is the core technology for CNC cutting machines to achieve "full-time cutting, cutting and high nesting rate cutting", and is the fundamental guarantee for effectively saving materials and improving cutting efficiency.

7. The cutting head adopts the fiber laser cutting head and capacitive sensing produced by the international brand Wanshunxing Company, with high sensing accuracy, sensitive response, stable and reliable performance.

8. Germany imported high-precision electronically controlled proportional valve to precisely control the gas pressure of the cutting auxiliary gas to achieve the best cutting effect.

Dapeng 6020 large metal fiber laser cutting machine suitable for materials and industry applications

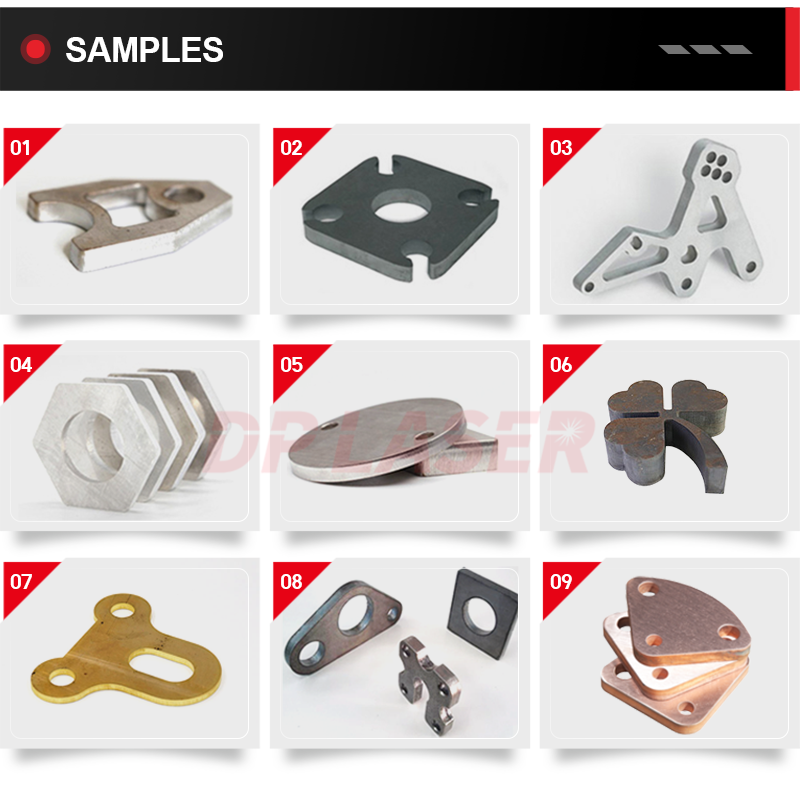

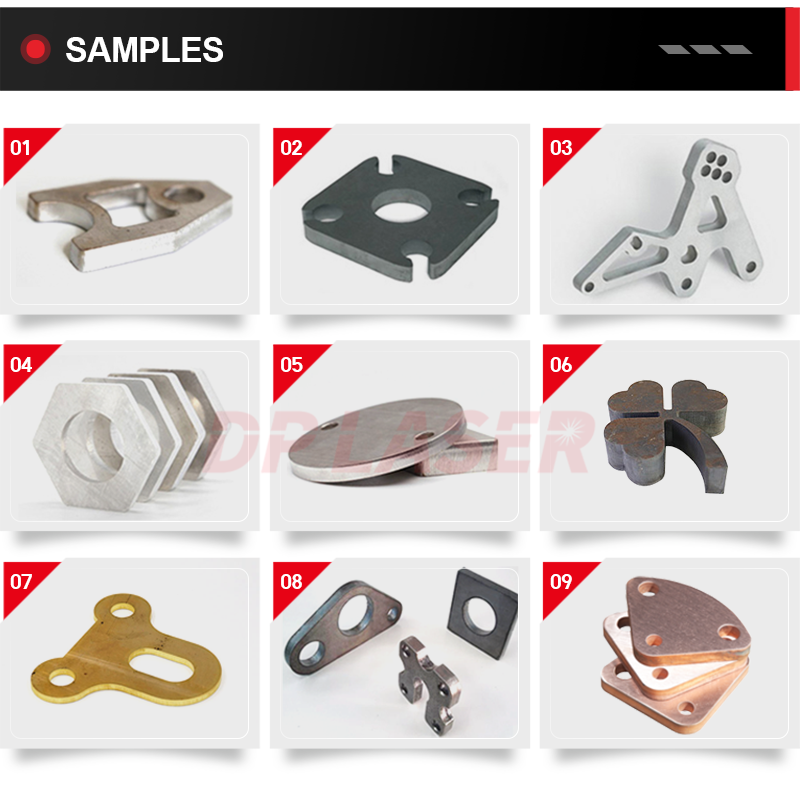

Applicable materials: professionally used for cutting various thin metal sheets, cutting 0.5~20mm carbon steel sheet, 0.5~12mm stainless steel sheet, and also cutting aluminum alloy sheet, galvanized sheet, electrolytic sheet, silicon steel, titanium alloy, galvanized sheet, Various metal materials such as thin brass plates.

Application industry: metal cutting, electrical switch manufacturing, elevator manufacturing, household appliance manufacturing, kitchenware manufacturing, tool processing, and other machinery manufacturing and processing industries.

| Working Area | 2500*1300 | 3000*1500 | 4000*1500 | 4000*2000 | 6000*1500 |

| X/Y Axis Positioning Accuracy | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm |

| X/Y Axis Repositioning Accuracy | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm |

Max. Moving Speed | 150m/min | 150m/min | 150m/min | 150m/min | 150m/min |

| Max.Acc Speec | 1.5G | 1.5G | 1.5G | 1.5G | 1.5G |

| Laser Power | 1000W-1500W | 1000W-6000W | 1500W-6000W | 1500W-6000W | 1500W-6000W |

| Laser Source | RAYCUS IPG nLIGHT MAX (Optional) |

| Laser Cutting Head | PRECITEC RAYTOOL WSX OSPRI (Optional) |

|

| Working Area | 6000*2000 | 6000*2500 | 8000*2500 | 10000*2500 | 12000*2500 |

| X/Y Axis Positioning Accuracy | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm |

| X/Y Axis Repositioning Accuracy | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm |

| Max. Moving Speed | 300m/min | 300m/min | 300m/min | 300m/min | 300m/min |

| Max.Acc Speec | 5.0G | 5.0G | 5.0G | 5.0G | 5.0G |

| Laser Power | 3000W-12000W | 3000W-20000W | 6000W-20000W | 6000W-20000W | 6000W-20000W |

| Laser Source | RAYCUS IPG nLIGHT MAX (Optional) |

| Laser Cutting Head | PRECITEC RAYTOOL WSX OSPRI (Optional) |