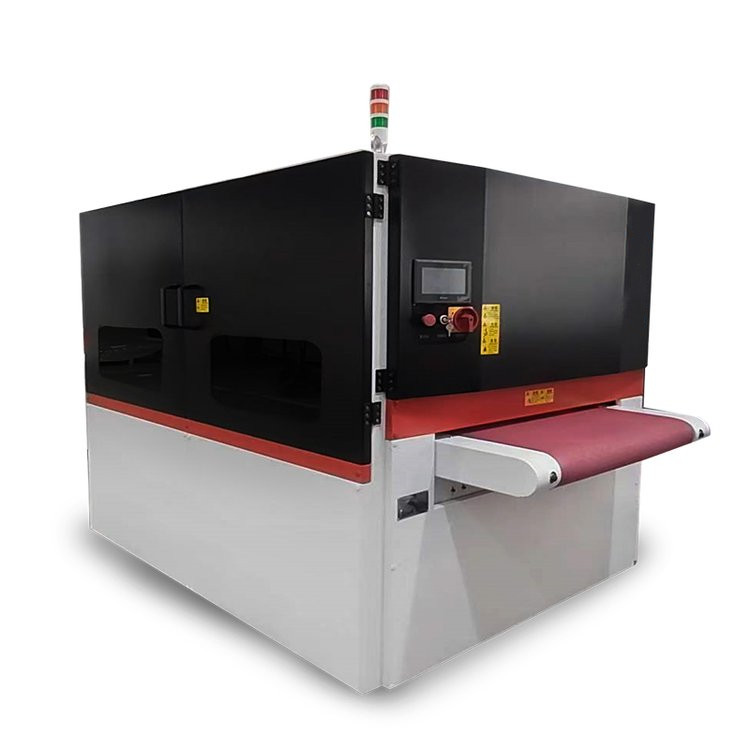

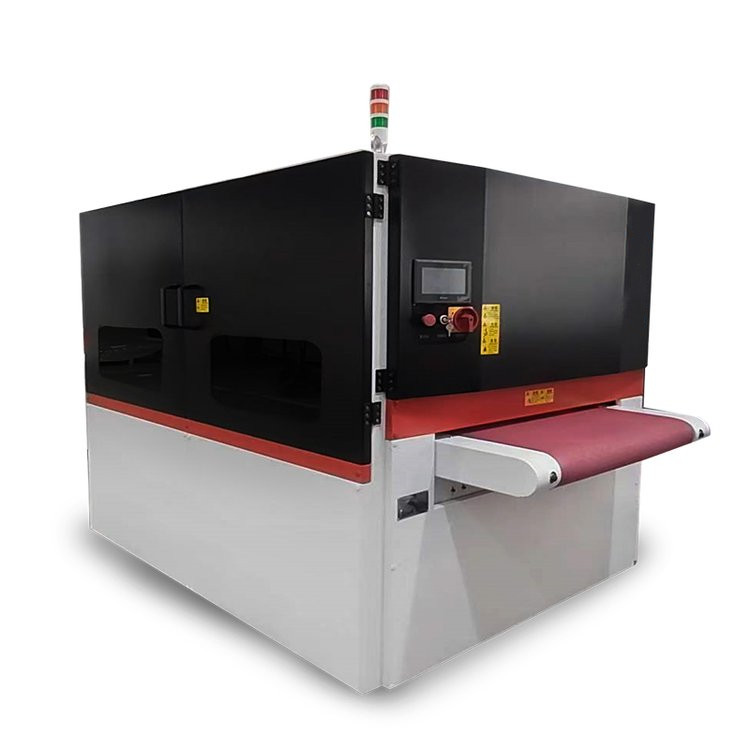

Deburring and Edge Rounding Machine (Model: MSP-L1000)

For Flame-Cut Metal Parts — Burr Removal, Edge Rounding, and Surface Smoothing

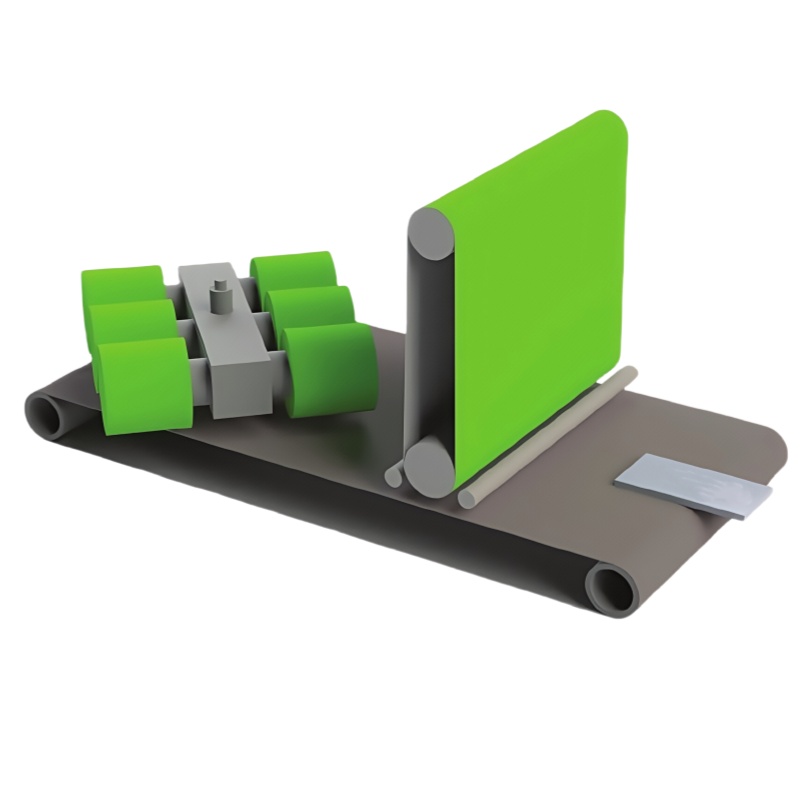

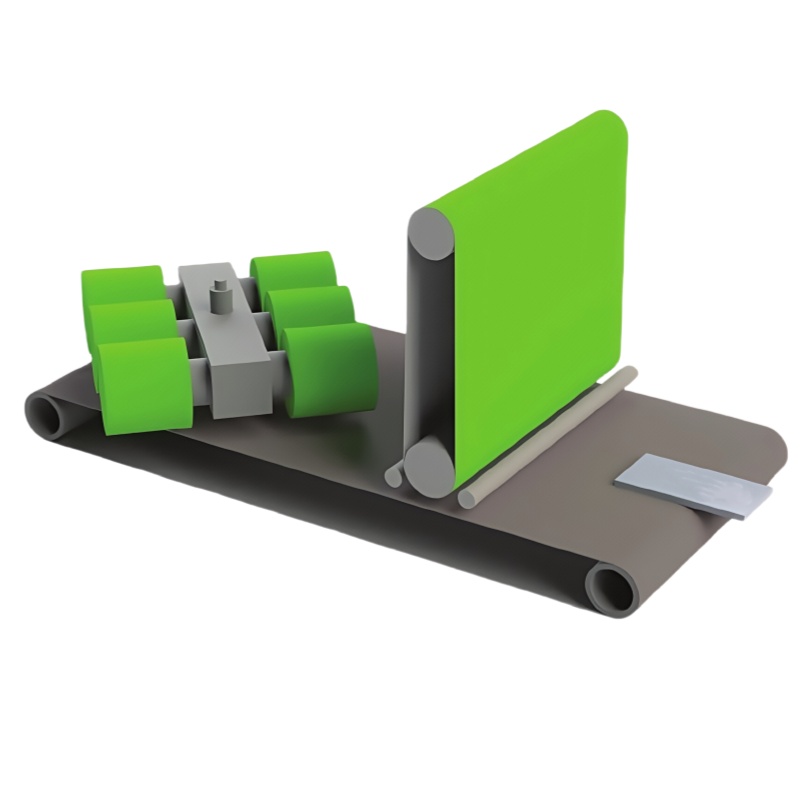

The MSP-L1000 Deburring and Edge Rounding Machine is engineered to remove burrs and sharp edges formed during flame cutting, laser cutting, or plasma cutting processes. This high-performance model delivers uniform edge rounding and smooth surfaces for steel, aluminum, and stainless steel components. With dual working stations – one sanding belt and six flap wheels – it offers high precision and consistent results on a wide range of metal parts.

Key Features:

Material Compatibility: Steel, Aluminum, Stainless Steel

Processing Functions: Deburring, Edge Rounding

High Precision Servo Adjustments: ±0.01 mm accuracy for thickness and brush compensation

Magnetic Workholding: Vacuum system optional for non-magnetic materials

Heavy-Duty Industrial Build: Designed for continuous production environments

Technical Specifications:

| Specification | Details |

| Max. Working Width | ≤ 1020 mm |

| Material Thickness | 0.5 – 80 mm |

| Min. Workpiece Size | 50 × 50 mm (non-perforated parts) |

| Total Power Consumption | 37.05 kW (excluding dust collection) |

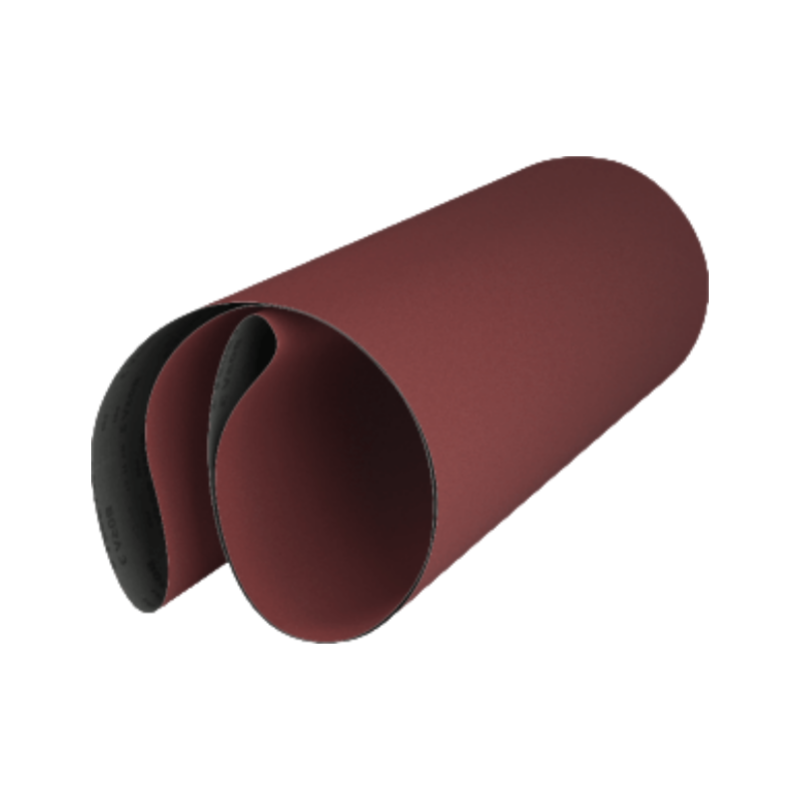

| Sanding Belt Size | Φ1910 mm × 1050 mm |

| Flap Wheel Size | Ø300 mm × 300 mm |

| Number of Flap Wheels | 6 pcs |

| Conveyor Speed | 0.5 – 6 m/min (inverter adjustable) |

| Sanding Belt Speed | Approx. 18 m/s |

| Brush Rotation Speed (Self-Rotation) | 8 – 26 m/s (inverter adjustable) |

| Brush Planetary Speed (Orbital Rotation) | 1 – 15 rpm (inverter adjustable) |

| Number of Planetary Axis Heads | 1 planetary unit with 6 rotating heads |

| Brush Compensation Servo Accuracy | 0.01 mm |

| Thickness Adjustment Accuracy | 0.01 mm |

| Grinding Media | Sanding belt + flap wheels |

| Dust Extraction Volume Required | 4000 m³/h |

| Machine Dimensions | Approx. 3000 mm (L) × 1950 mm (W) × 2150 mm (H) |

| Machine Weight | Approx. 3000 kg |

| Workholding System | Magnetic (vacuum optional) |

Abrasive Types Supported:

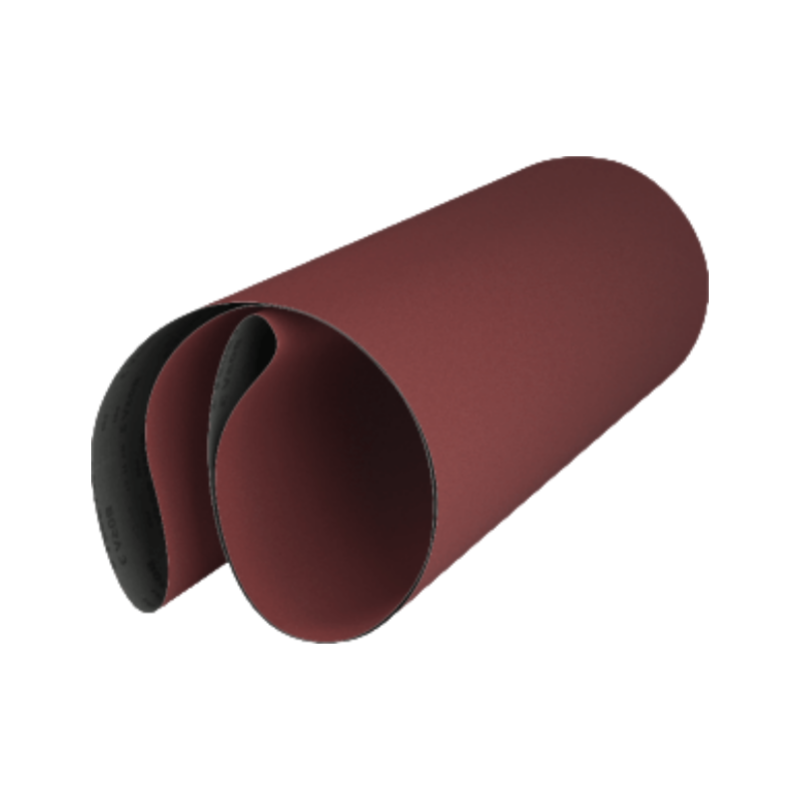

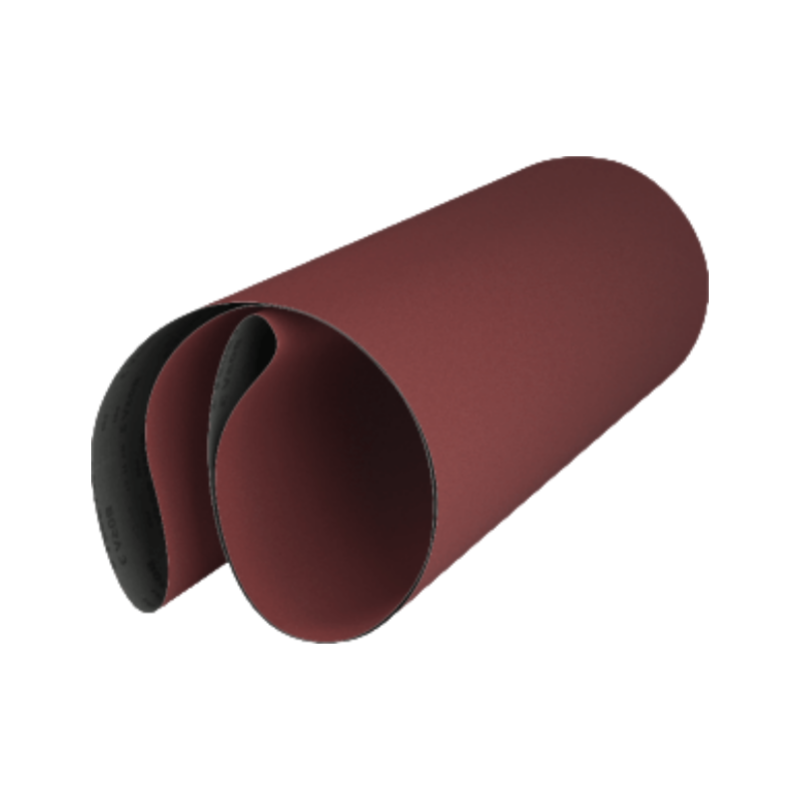

Ceramic Emery Belts

Zirconium Emery Belts

Aluminum Oxide Belts

Cubitron Belts

Scotch-Brite Belts

Core Components & Configuration:

| Item | Specification | Purpose | Brand |

| Sanding Belt Main Grinding Wheel | Φ185 mm × 1050 mm | Belt grinding | - |

| Main Motor for Belt | 11 kW | Drives sanding belt | Shiyang |

| Flap Wheel Self-Rotation Motors | 2.2 kW × 3 | Flap wheel rotation | Shiyang |

| Flap Wheel Planetary Motor | 750 W | Flap wheel orbital motion | Shengbang |

| Servo for Brush Wear Compensation | 750 W | Compensates flap wheel wear | Weichuang |

| Conveyor Belt | 1050 mm wide | Material transport | Local |

| Conveyor Drive Motor | 2.2 kW | Drives conveyor | Xinling |

| Conveyor Reducer | Hypoid gear | Conveyor transmission | Xinling |

| Table Lifting Servo | 750 W | Workpiece thickness control | Weichuang |

| Sanding Belt Tracking Sensor | – | Detects belt deviation | Shanghai Hugong |

| Belt Tension Cylinder | ACQ80×30 | Tension adjustment | Airtac |

| Tracking Correction Cylinder | SDA63×5 | Belt alignment | Airtac |

| Inverter for Brush Rotation | 7.5 kW | Speed control | Weichuang |

| Inverter for Brush Planetary | 750 W | Speed control | Weichuang |

| Conveyor Inverter | 2.2 kW | Conveyor speed control | Weichuang |

| Vacuum Inverter | 15 kW | Negative pressure system | Weichuang |

| Vacuum Fan | 15 kW | Workpiece holding | Jiuzhou |

| High-Speed Bearings | Full set | Rotary support | NSK |

| Low Voltage Electrical | – | Control panel | Chint |

| PLC Control System | – | Central control | Weichuang |

| Touchscreen HMI | 7 inch | User interface | Weichuang |