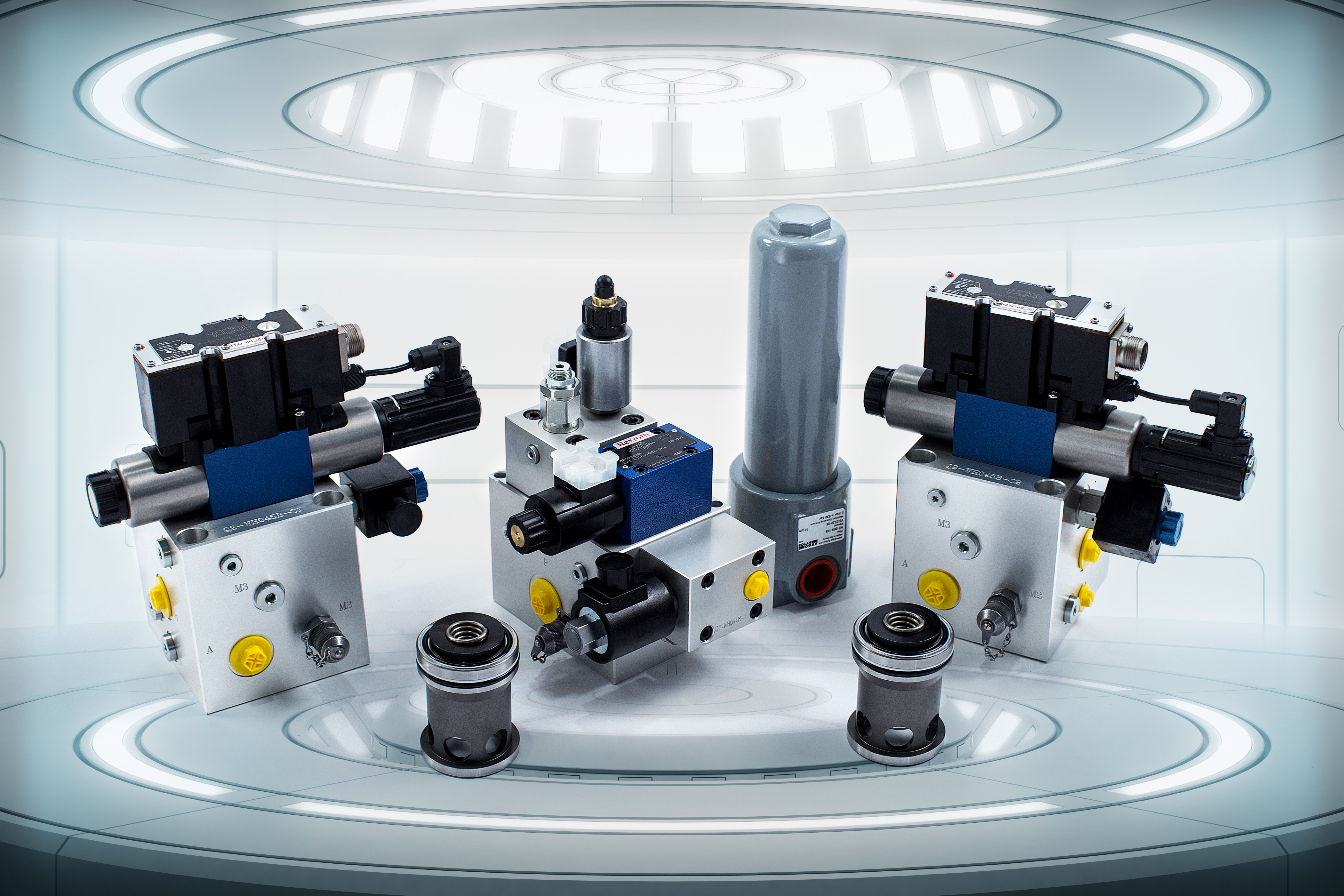

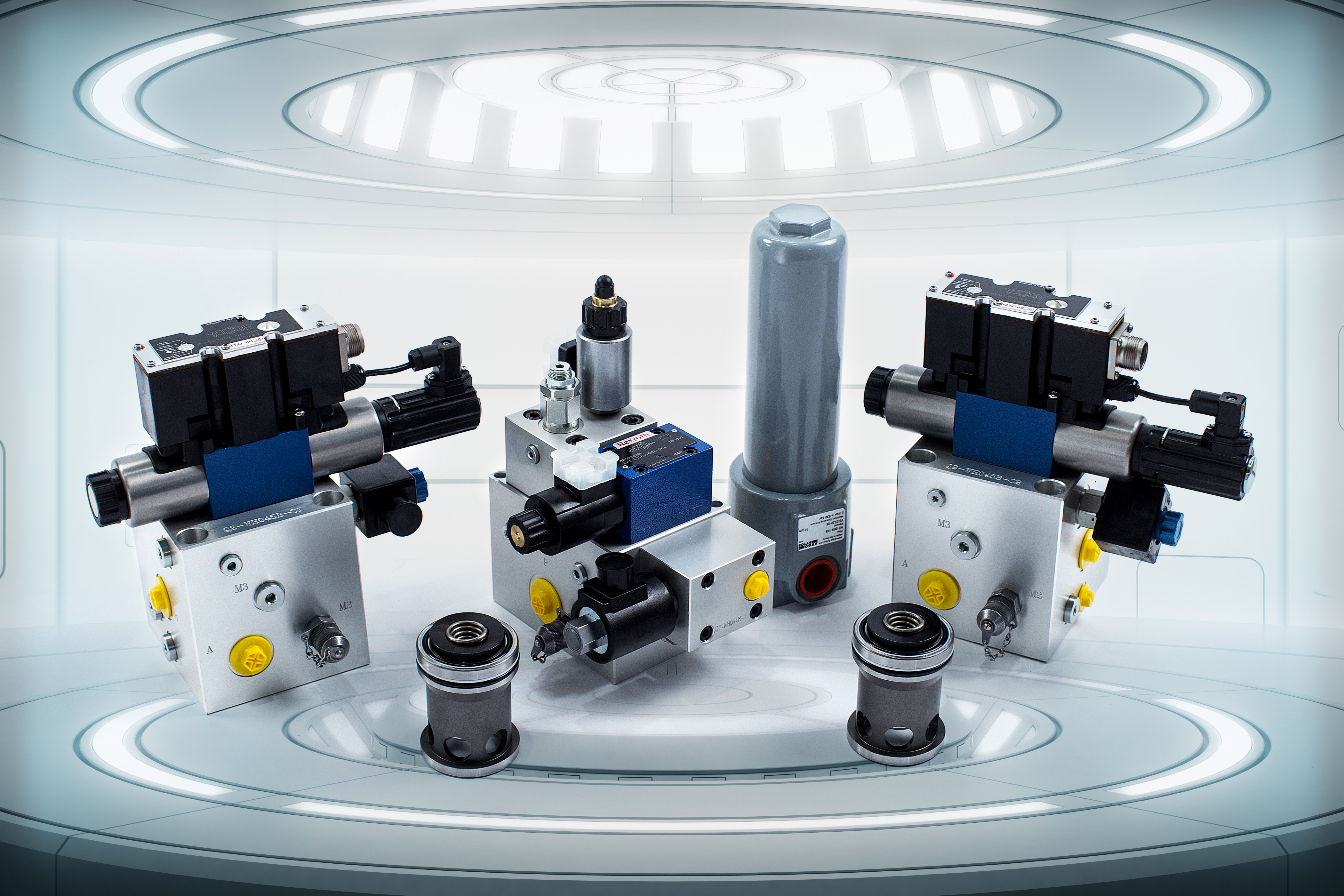

The Electro-Hydraulic Proportional System PV50 is typically used in applications requiring precise control over hydraulic fluid flow and pressure. In the context of press brakes, it would be used for larger and more powerful machines, such as the 63T, 110T, 125T–170T, 200T–250T, and 300T–320T models, which require robust and accurate hydraulic control systems.

Key Features of Electro-Hydraulic Proportional System PV50:

Electro-Hydraulic Proportional Control: The PV50 valve is designed to provide smooth and precise control over the flow and pressure of hydraulic fluid, allowing for more accurate positioning and control in press brake operations.

Precise Bending Control: It enables precise control over the bending force and angle, ensuring that the workpiece is bent to exact specifications.

Enhanced Efficiency: The proportional control of the valve ensures that only the necessary amount of hydraulic fluid is used, which can increase overall energy efficiency in the press brake system.

High Performance: The PV50 is suitable for handling higher pressures and flow rates, making it an ideal choice for heavy-duty press brake applications in the specified tonnage range (63T, 110T, 125T–170T, 200T–250T, 300T–320T).

Versatility: This system can be used in a wide range of press brake configurations, offering flexibility for different bending tasks.

Reliability and Durability: The PV50 valve provides long-lasting performance under high loads, ensuring reduced downtime and lower maintenance costs for press brake machines.

Integration: The PV50 system can be integrated with the CNC control system, providing seamless coordination between the hydraulic and electronic components of the press brake for improved overall control and automation.

Product Features:

Fast Positioning: Adopts high-response proportional servo valve with a response frequency of 80–100Hz.

Precision: Positioning accuracy reaches 0.01mm.

Compact Design: Integrated high-pressure filter.

Functionality: Built-in hydraulic deflection compensation function.

Feedback: Equipped with an LVDT displacement sensor for enhanced accuracy control.

Specifications and Configuration Table:

| Configuration | 30T–50T | 63T | 110T | 125T–170T | 200T–250T | 300T–320T |

| Normally Open Valve | PV32 | PV50 | PV50 | PV50 | PV50 | PV50 |

| Normally Closed Valve | SVF–32–21C | SVF–40–21C | SVF–40–21C | SVF–40–21C | SVF–50–21C | SVF–50–21C |

| Oil Pump | 10cc | 16cc | 20cc | 25cc | 32cc | 40cc |

| Servo Valve | NG6 | NG6 | NG6 | NG6 | NG6 | NG6 |

Understanding Components of The Press Brake

Understanding Components of a Press Brake

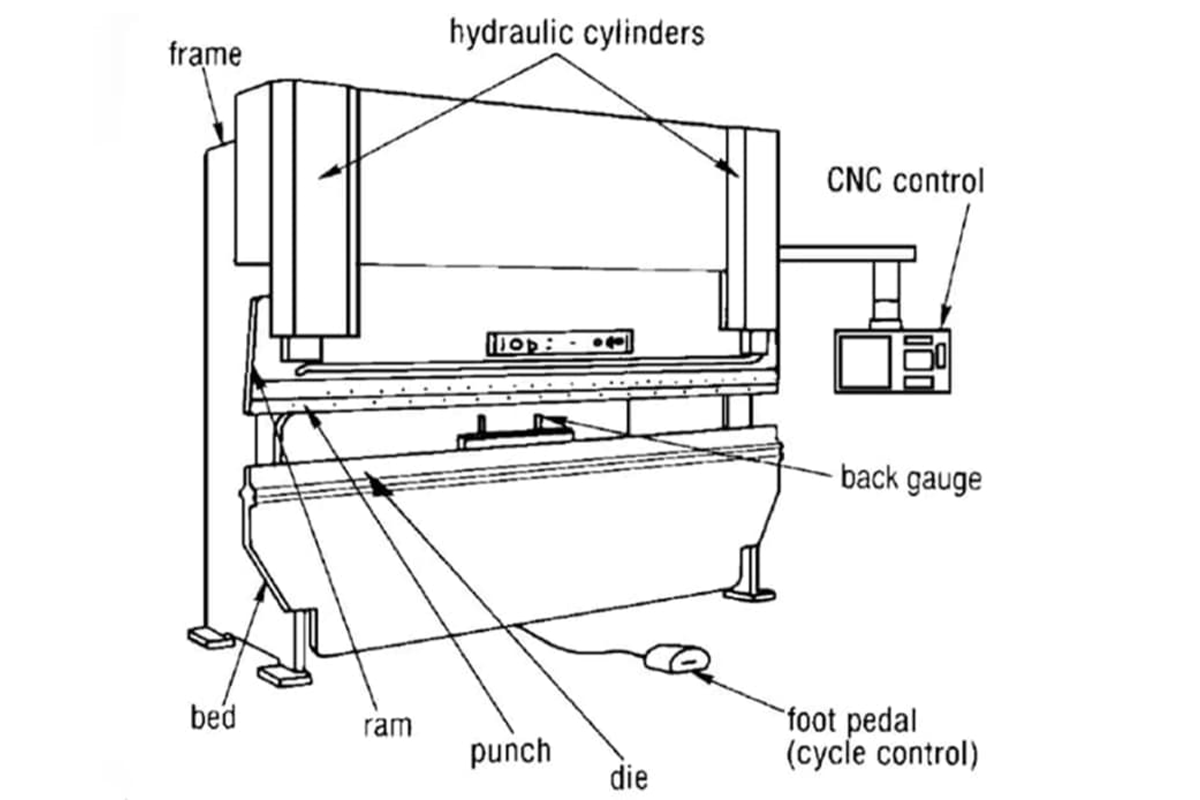

A press brake is a machine tool used for bending sheet metal into various shapes. Below is a detailed explanation of its key components and their functions:

1. Frame

The frame forms the structural foundation of the press brake, providing stability and rigidity during operation. It is crucial for consistent bending results and ensures the machine can withstand the high forces involved without distortion.

Types:

C-Shaped Frame: Compact and suitable for smaller, less powerful machines.

Square Frame: Rigid and designed for heavy-duty operations with larger sheets of metal.

2. Bed

The bed is a flat, stationary surface where the workpiece is placed during bending. It ensures proper alignment of the material and supports the bending process.

3. Ram

The ram is a movable upper component that exerts downward force on the workpiece. It is connected to the punch, directly contacting the metal during the bending process.

4. Punch and Die

Punch: A tool with a specific shape mounted on the upper beam to deform the material during bending.

Die: A complementary tool installed on the lower beam, designed to shape the material into the desired form. Together, the punch and die define the final shape of the bent workpiece.

Understanding Components of a Press Brake

A press brake is a machine tool used for bending sheet metal into various shapes. Below is a detailed explanation of its key components and their functions:

1. Frame

The frame forms the structural foundation of the press brake, providing stability and rigidity during operation. It is crucial for consistent bending results and ensures the machine can withstand the high forces involved without distortion.

Types:

C-Shaped Frame: Compact and suitable for smaller, less powerful machines.

Square Frame: Rigid and designed for heavy-duty operations with larger sheets of metal.

2. Bed

The bed is a flat, stationary surface where the workpiece is placed during bending. It ensures proper alignment of the material and supports the bending process.

3. Ram

The ram is a movable upper component that exerts downward force on the workpiece. It is connected to the punch, directly contacting the metal during the bending process.

4. Punch and Die

Punch: A tool with a specific shape mounted on the upper beam to deform the material during bending.

Die: A complementary tool installed on the lower beam, designed to shape the material into the desired form. Together, the punch and die define the final shape of the bent workpiece.

5. Back Gauge

The back gauge is a precision positioning system located at the rear of the press brake.

6. Control Panel

The control panel is the user interface for operating the press brake.

On CNC press brakes, it allows programming of bending angles, material thickness, and complex sequences, improving precision and efficiency.

7. CNC System

The CNC (Computer Numerical Control) system automates press brake movements, including:

This system ensures high precision and simplifies multi-step operations.

8. Upper and Lower Beams

9. Axes

X-Axis: Controls the back gauge's horizontal movement along the press brake length for flange adjustment.

Y-Axis: Controls the vertical movement of the ram or punch for bending operations.

Z-Axis: Adjusts the back gauge's horizontal positioning along the left and right directions.

R-Axis: Controls the back gauge fingers’ vertical movement for complex or multiple bends.

10. Sheet Support Arms

Mounted at the machine's front, these arms support the workpiece during bending, ensuring alignment and reducing operator strain.

11. Housing Brace

A structural component that connects the two driving cylinders on the upper beam, maintaining machine stability.

12. Foot Pedal

Used by the operator to engage the machine's clutch or initiate bending operations.

13. Crank Shaft

In mechanical press brakes, this component transfers the flywheel's energy to the ram, ensuring efficient energy conversion.