Embedded 1 NM³ Nitrogen Generator for Laser Cutting and Welding – Model ZHN-01

The ZHN-01 Embedded Nitrogen Generator is a compact and efficient device engineered specifically for industrial laser cutting and welding applications. By providing high-purity nitrogen (99.99%) consistently, this generator ensures precise, clean results while optimizing energy efficiency and reliability.

Product Specifications

| Parameter | Details |

| Model | ZHN-01 (Embedded) |

| Nitrogen Flow Rate | 1 NM³/h |

| Nitrogen Purity | 99.99% |

| Inlet Air Pressure | 0.6–0.8 MPA |

| Nitrogen Output Pressure | ≤0.6 MPA |

| Power Consumption | 15 W |

| Supply Voltage | AC220V |

| Dimensions (L×W×H) | 550 × 165 × 690 mm |

| Ports | Air Inlet (8 mm air pipe), Nitrogen Outlet (6 mm air pipe) |

Core Features

High Purity and Stable Nitrogen Output

The generator produces nitrogen with a purity of 99.99%, making it ideal for industrial processes such as laser cutting, where oxidation can negatively impact the cutting surface, and welding, where contamination needs to be minimized.

Compact Embedded Design

With a sleek and space-saving form factor (550 × 165 × 690 mm), the ZHN-01 is perfect for embedding into existing systems or equipment cabinets, saving valuable workspace in industrial environments.

Advanced Pressure Swing Adsorption (PSA) Technology

This nitrogen generator uses PSA technology to separate nitrogen from compressed air. The process alternates between two molecular sieve tanks, Tower A and Tower B, ensuring a continuous flow of nitrogen while one tower regenerates.

Programmable Time Relay

The integrated programmable time relay manages the working order and pressure relief times of the A and B towers. This ensures optimal efficiency and performance. Settings are pre-configured at the factory, requiring no user adjustments under normal circumstances.

Detailed Functional Components

Nitrogen Pressure Gauge:

Displays real-time pressure values in the nitrogen storage tank, allowing operators to monitor the output pressure for consistent performance.

Pressure Gauges for Towers A and B:

These gauges show the real-time pressure values within the A and B molecular sieve tanks. During operation, only one tank is actively working, while the other undergoes pressure relief or is in a low-pressure state to regenerate the sieves.

Air Inlet:

The air inlet is designed for an 8 mm air pipe. To ensure efficient operation, the compressed air source must be filtered to remove moisture and oil before being connected to the nitrogen generator.

Nitrogen Outlet:

The nitrogen outlet uses a 6 mm air pipe, providing a direct connection for clean, high-purity nitrogen to be used in laser cutting or welding applications.

Advantages of the ZHN-01 Nitrogen Generator

Energy Efficiency

The generator operates at just 15W, significantly reducing energy consumption compared to traditional nitrogen supply methods. This ensures lower operational costs over time.

Continuous Operation

With its alternating tower system, the ZHN-01 provides an uninterrupted nitrogen supply, vital for continuous industrial processes like laser cutting and welding.

Ease of Installation and Maintenance

The ZHN-01 is designed for quick setup with minimal maintenance requirements. Clear ports and pre-configured settings simplify installation and daily operation.

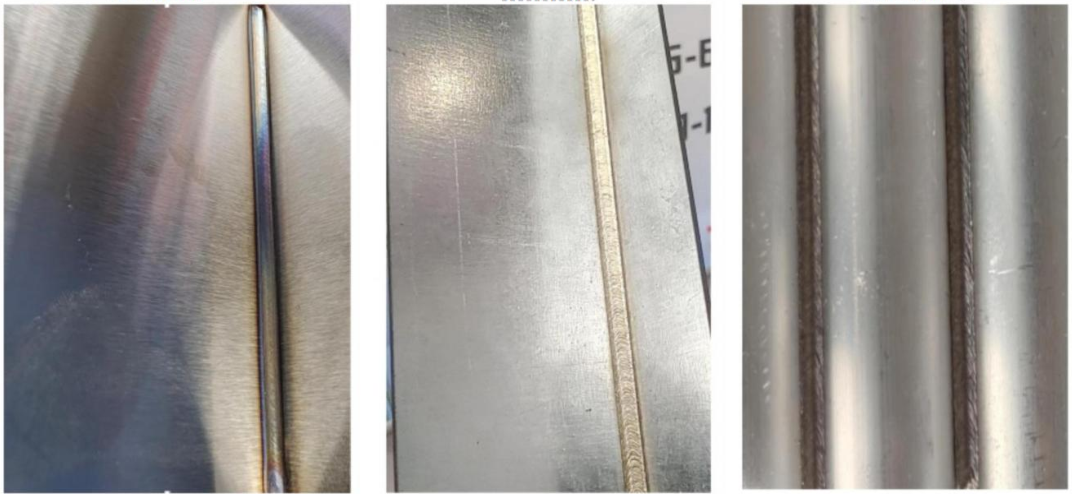

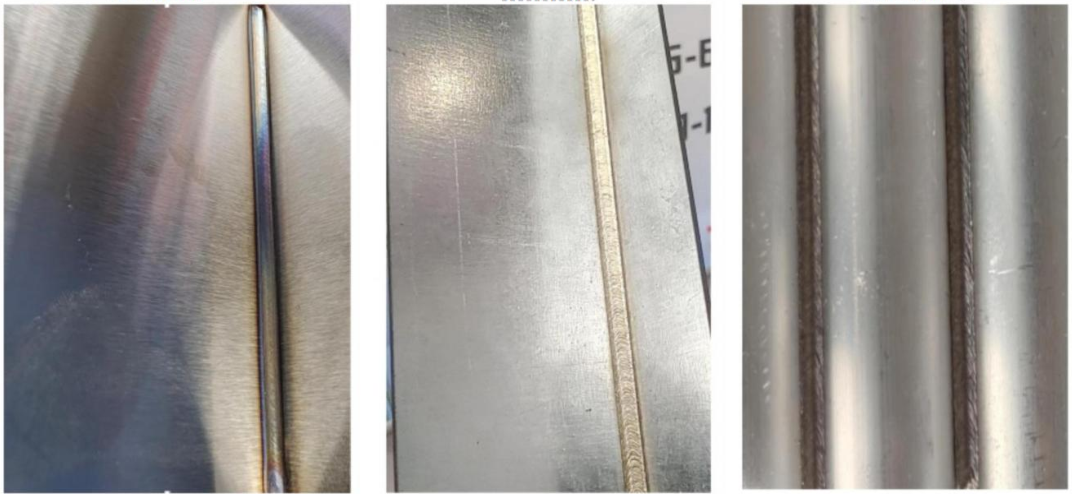

Enhanced Process Quality

By providing high-purity nitrogen, the generator helps to improve cutting precision, ensure cleaner welds, and prevent contamination during manufacturing processes.

Applications

The ZHN-01 Embedded Nitrogen Generator is versatile and applicable across various industries, including:

Laser Cutting: Prevents oxidation, delivering smooth and precise cutting results.

Welding: Provides a protective inert atmosphere for welds, improving quality and durability.

Electronics Manufacturing: Ensures a contamination-free environment for assembling sensitive components.

Food and Beverage Packaging: Extends shelf life by maintaining product freshness through nitrogen flushing.

Pharmaceutical Production: Supports sterile environments essential for manufacturing medical products.

Installation and Connection

Compressed Air Requirements:

Before connecting the air source to the nitrogen generator, ensure it is free of oil and moisture using a suitable filtration system.

Port Connections:

Power Supply:

The generator operates on a standard AC220V power source, ensuring compatibility with most industrial setups.