Nitrogen Generator for Laser Cutting and Welding – Model ZHN-01

The ZHN-01 Nitrogen Generator is designed to deliver high-purity nitrogen with exceptional efficiency, specifically catering to the needs of laser cutting and welding operations.

Specifications

| Parameter | Details |

| Model | ZHN-01 |

| Nitrogen Flow Rate | 1 NM³/h |

| Nitrogen Purity | 99.99% |

| Inlet Pressure | 0.6–0.8 MPA |

| Nitrogen Output Pressure | ≤0.6 MPA |

| Power Consumption | 15 W |

| Supply Voltage | AC220V |

| Dimensions (L×W×H) | 500 × 450 × 780 mm |

| Ports | Air Inlet, Nitrogen Outlet |

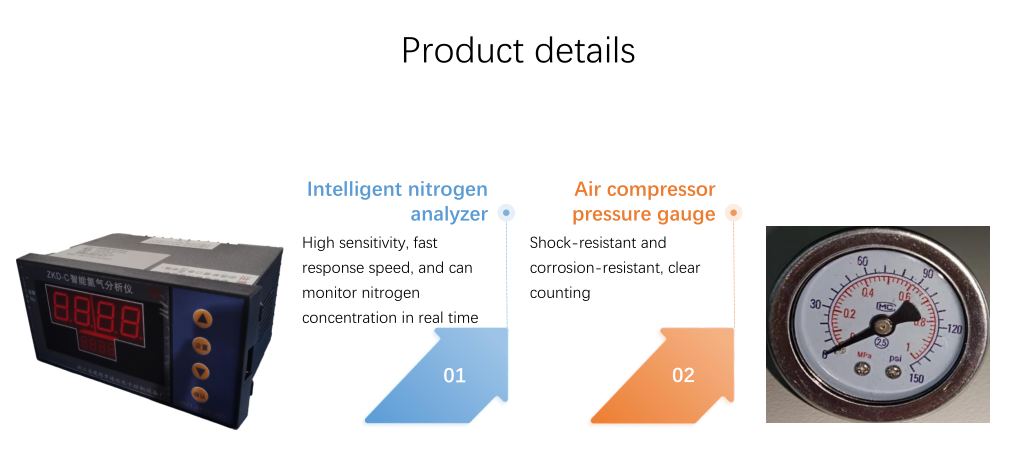

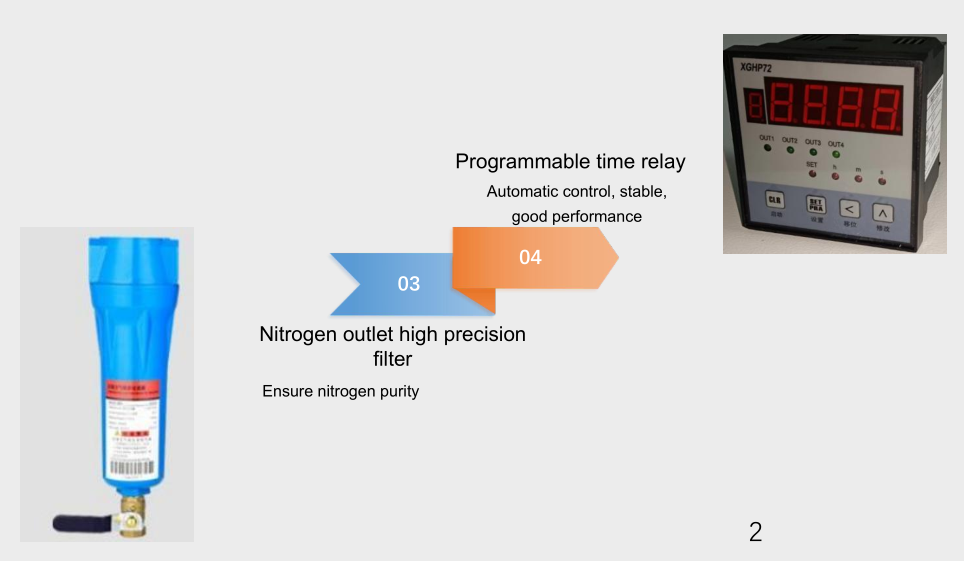

Core Components and Parameters

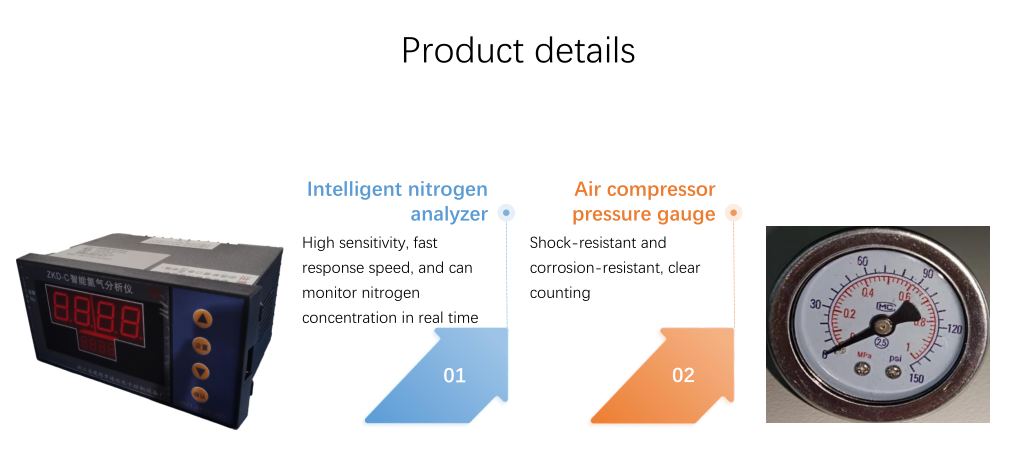

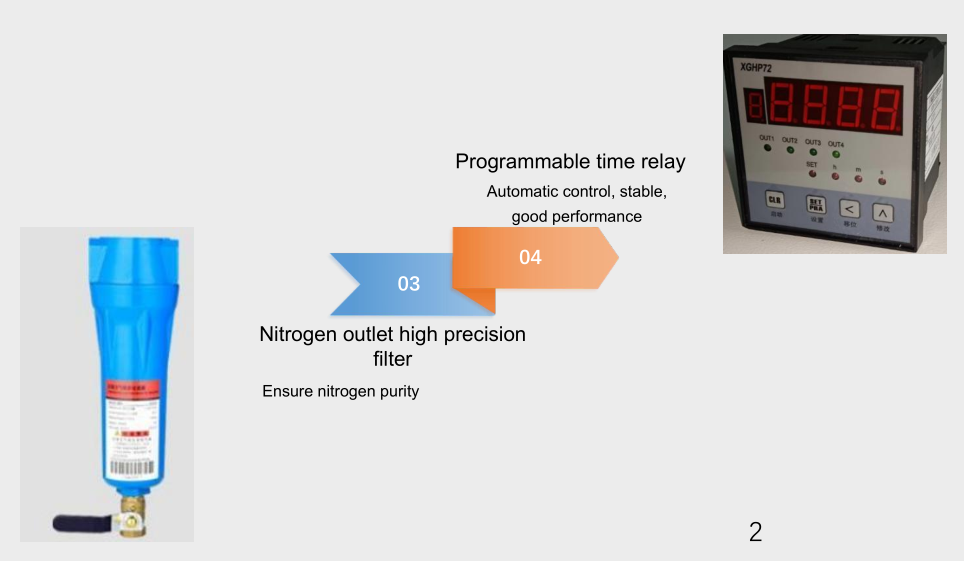

The ZHN-01 Nitrogen Generator incorporates an advanced carbon molecular sieve system to ensure high nitrogen purity. Its compact design houses essential features, making it an ideal choice for industrial environments.

Air Pressure Gauge:

Located on the front panel, the air pressure gauge allows operators to monitor the inlet pressure in real time. The normal operating range for the air pressure is between 0.6 and 0.8 MPA. This ensures that the generator receives adequate pressure for optimal nitrogen production.

Nitrogen Pressure Gauge:

This gauge displays the pressure inside the nitrogen tank, providing a real-time reading to ensure the nitrogen output remains stable and within the specified limit (≤0.6 MPA).

Tower A and Tower B Pressure Gauges:

These gauges monitor the pressure in the two carbon molecular sieve tanks, Tower A and Tower B. During operation, only one tank is active, while the other undergoes pressure relief or operates at a low-pressure state to regenerate the molecular sieves. This alternating process ensures continuous nitrogen production without interruption.

Operational Overview

The ZHN-01 operates on the principle of pressure swing adsorption (PSA). This technology separates nitrogen from compressed air by utilizing the adsorption properties of carbon molecular sieves. Key stages in the operational cycle include:

Air Compression and Purification:

Compressed air enters the generator through the inlet port, where it undergoes initial filtration to remove moisture, oil, and other impurities.

Adsorption in Carbon Molecular Sieves:

The purified air is directed into Tower A or Tower B. The carbon molecular sieves selectively adsorb oxygen, carbon dioxide, and water vapor, allowing high-purity nitrogen to pass through.

Tower Switching and Regeneration:

While one tower is producing nitrogen, the other is in the regeneration phase, releasing adsorbed gases at a lower pressure. This cyclical switching ensures consistent nitrogen output.

Nitrogen Storage and Delivery:

The generated nitrogen is stored in the nitrogen tank and delivered to the outlet at a controlled pressure, ready for use in laser cutting or welding operations.

Advantages of the ZHN-01

High Purity Nitrogen:

With a purity level of 99.99%, the ZHN-01 meets the stringent requirements for industrial applications, ensuring clean and precise operations.

Energy Efficiency:

Consuming only 15 W, the generator is designed to minimize energy usage, reducing operational costs.

Compact and Durable Design:

With dimensions of 500 × 450 × 780 mm, the ZHN-01 fits seamlessly into workshop environments while maintaining robust performance.

Easy Monitoring and Maintenance:

The clearly labeled gauges and intuitive layout make it simple for operators to monitor system performance and perform routine maintenance.

Applications

The ZHN-01 Nitrogen Generator is tailored for use in industries that demand high-quality nitrogen, including:

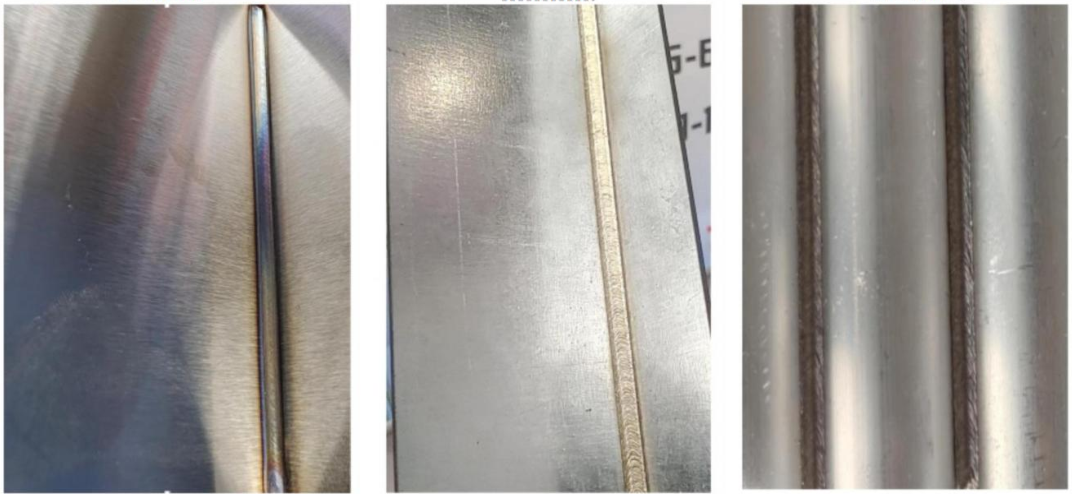

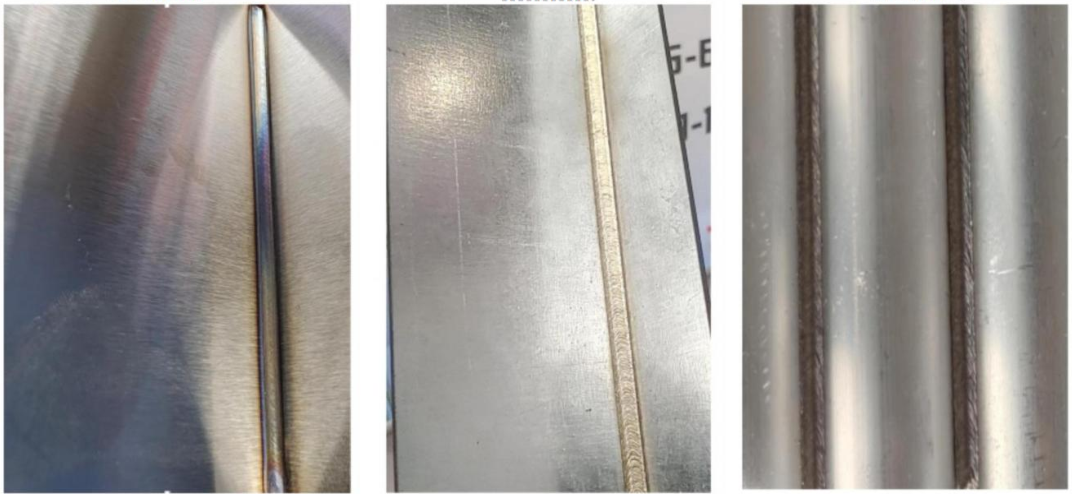

Laser Cutting: Ensures smooth cutting edges and prevents oxidation during the process.

Welding: Protects welds from contamination, enhancing durability and finish quality.

Electronics Manufacturing: Provides an inert environment to safeguard sensitive components.

Pharmaceuticals: Maintains sterility during production processes.

Panel and Back Port Diagram Description

The front panel of the ZHN-01 houses the air pressure gauge, nitrogen pressure gauge, and tower pressure gauges for easy access and visibility. The air inlet and nitrogen outlet ports are strategically located at the back, along with clearly marked connectors for streamlined installation and operation.