Glass Laser Cutting and Splitting Machines

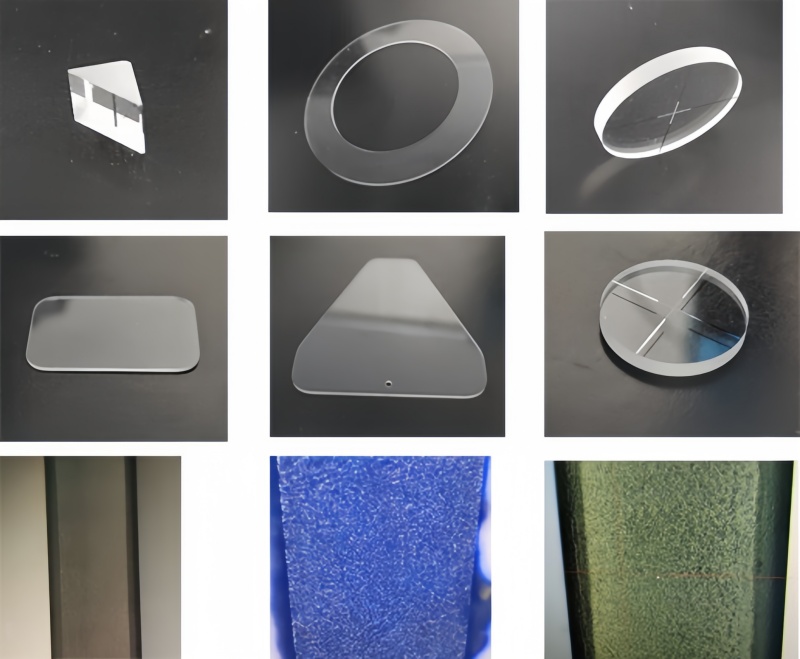

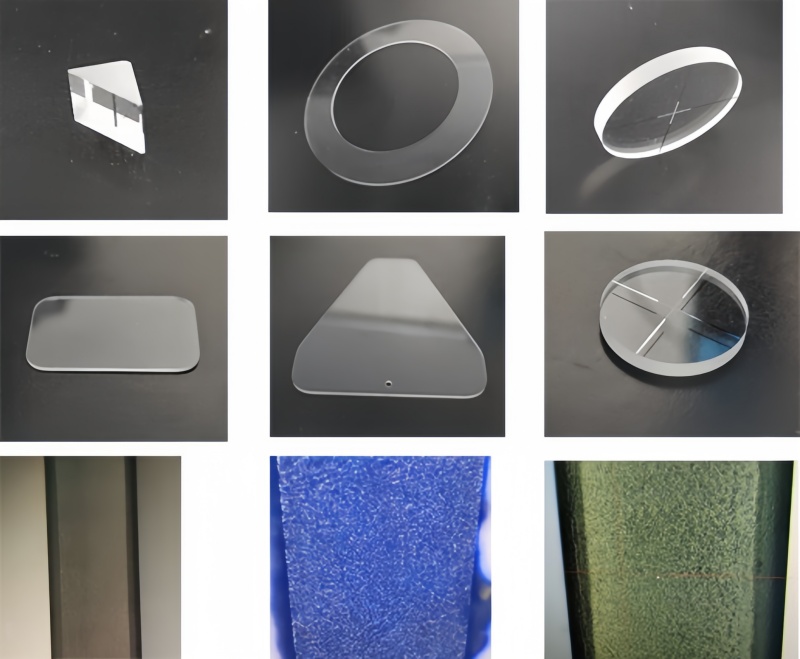

Glass Laser Cutting and Splitting Machines are advanced industrial systems designed to process various types of glass with high precision and efficiency. These machines combine cutting and splitting functions, using laser technology to cut and divide brittle glass materials, such as sapphire, optical glass, smartphone covers, and glass sheets.

These machines are used in industries like electronics, optics, automotive, and packaging, where glass components need to be precisely cut, split, or perforated without causing material damage.

Laser Cutting and Splitting Integrated Machine

| No. | Item | Technical Parameters |

| 1 | Laser Wavelength | 1064nm Picosecond Laser |

| 2 | Minimum Focused Spot Size | 2μm |

| 3 | Cutting Laser Power | 70W |

| 4 | Splitting Laser Power | CO2 |

| 5 | Assembly Laser Power | 100W |

| 6 | Laser Lifetime | ≥20,000 hours |

| 7 | Cutting Method | Cutting Head Type |

| 8 | Platform Motion Range & Speed | 1000mm, Maximum Acceleration 1G |

| 9 | Positioning Accuracy | ≤2μm |

| 10 | Cutting/Splitting Range | 600mm x 700mm |

| 11 | Cutting/Splitting Max Thickness | ≥7.5mm |

| 12 | Machine Control System Software | Laser Studio (Integrated vision, optics, and motion) |

| 13 | Power Requirements | 380V / 50Hz, Approx. 5KVA |

| 14 | Total Machine Weight | 5000kg |

Overview of the Equipment:

This system uses a 1064nm picosecond laser, offering high peak power and fine cutting capability, ideal for brittle materials like glass and sapphire.

The machine utilizes a CO2 laser for the splitting process, ensuring minimal thermal impact and precision for splitting fragile materials.

The maximum cutting/splitting thickness is 7.5mm, suitable for thicker glass or other brittle materials.

Platform motion range reaches 1000mm, with a maximum acceleration of 1G, ensuring high efficiency and precision during operations.

Applications:

This Laser Cutting and Splitting Integrated Machine is widely used in:

Electronics Industry: For cutting and perforating smartphone covers, sapphire glass, optical glass, etc.

Optical Components: For high-precision cutting and splitting of optical elements, lenses, laser windows, etc.

Precision Manufacturing: Suitable for cutting brittle materials like glass, ceramics, sapphire, etc.

Features and Advantages:

High Precision: With picosecond laser technology and a high-precision motion system, the machine achieves an extremely high cutting precision, with a minimum focused spot size of 2μm, ensuring excellent cutting quality.

Long Lifespan: The laser has a long service life of up to 20,000 hours, reducing maintenance and replacement costs.

High-Speed Processing: The platform can reach speeds of up to 1000mm/s and has an acceleration of 1G, significantly boosting productivity.

Automated Control: The system integrates vision technology and laser cutting control, enabling automatic positioning, cutting, and splitting, which simplifies operation and enhances automation.