Laser Cutting and Splitting Integrated Machine for Glass

This Laser Cutting and Splitting Integrated Machine is designed to perform precision cutting and perforation of various materials used in the electronics industry, including sapphire glass windows, smartphone covers, optical glass, and other brittle materials. It combines high-speed, high-precision cutting with an automated system for efficient product processing. The machine features modular design, offering flexibility and ease of expansion.

Key Features:

High Precision and Speed:

The system uses linear motors with a dual-platform structure, providing high precision, speed, and stability for both cutting and splitting operations.

Cutting Head: High-speed cutting with excellent cutting effects.

CCD Positioning System:

User-Friendly Design:

Modular Design:

Material Compatibility:

Ideal for transparent, brittle materials such as sapphire glass (used in camera windows and smartphone covers), optical glass, and other materials used in the electronics industry.

Operating Principle:

Product Loading and Positioning:

Cutting Process:

The CCD system accurately locates the product, and cutting is performed.

After cutting, the product moves to the rear area for splitting.

Post-Processing:

Fixture 2:

Platform and Motion System:

Marble Platform:

Linear Motors (X/Y Axes):

Uses linear motors with optical scales and a dual-position platform for fast, precise movement.

The motion control system utilizes closed-loop control, ensuring high precision without physical contact between the stator and rotor, resulting in no wear over time.

Movement Specifications:

Flatness of Marble Platform: ±0.01mm

Platform Type: Dual-position platform

X/Y Axes Stroke: 1620 x 1410 mm

Maximum Speed: ≤1000mm/s

Acceleration: ≥10000mm/s²

Positioning Accuracy: ≤ ±3μm

Repeat Positioning Accuracy: ≤ ±3μm

Laser Cutting Module:

Pico-second Laser:

Optical Path Module:

Z-Axis Module (Cutting Head, Vision System, Servo Motor):

Cutting Head: Ensures no tapering, minimal debris, and edge collapse, with high strength.

Vision System: Equipped with a CCD camera, lenses, and coaxial light source for precise alignment and high accuracy.

Laser Splitting Module:

CO2 Laser:

Optical Path Module:

Z-Axis Module (Splitting Head, Vision System, Servo Motor):

Splitting Head: Ensures no residue, minimal edge collapse, and high strength.

Vision System: Equipped with a CCD camera, lenses, and coaxial light source for precise positioning.

Laser Cutting and Splitting Integrated Machine

This Laser Cutting and Splitting Integrated Machine combines pico-second laser cutting, CO2 laser splitting, and an automatic loading/unloading system to handle the precision cutting and separation of transparent and brittle materials. The machine utilizes a pico-second laser for focused beam cutting, while the CO2 laser heats the cut lines to separate the product from waste material through thermal expansion and contraction.

Key Features:

Applications:

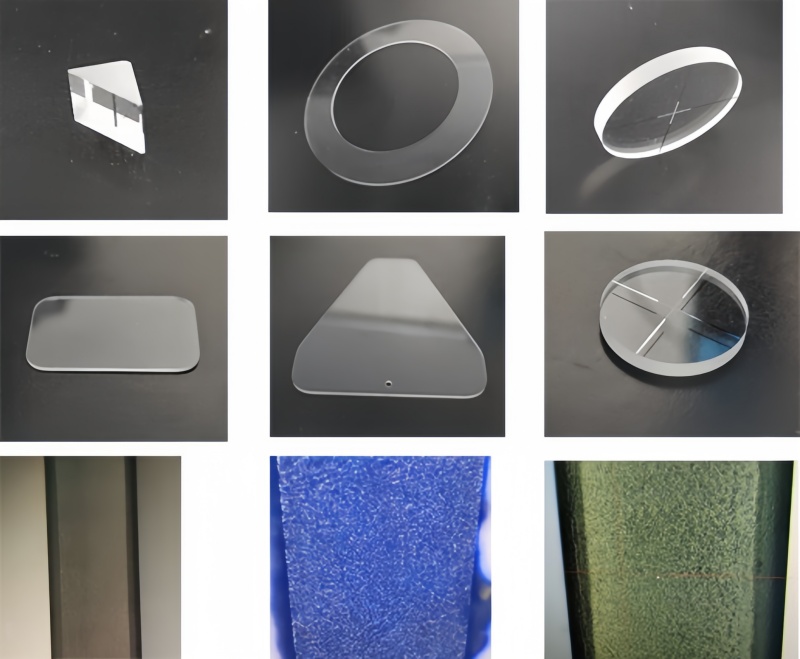

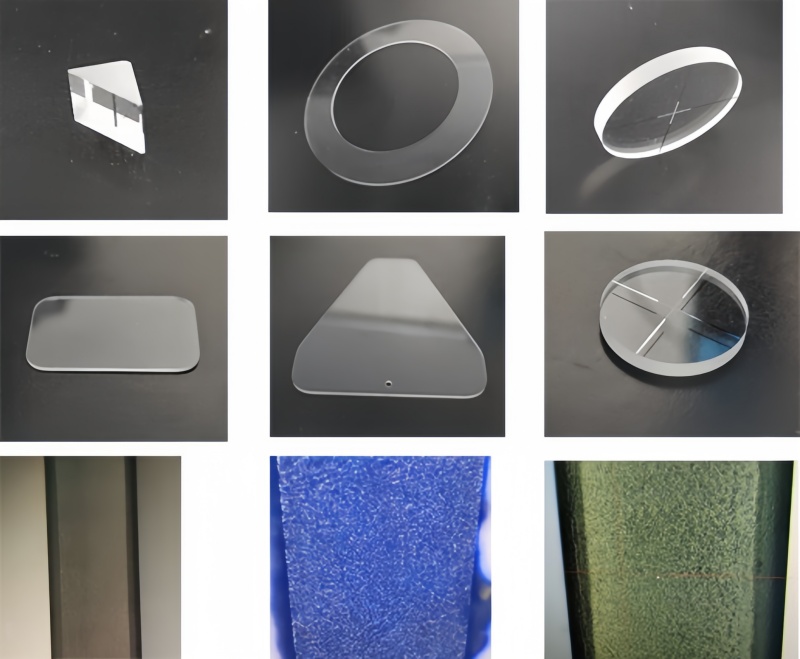

Sample Display:

Sample parts processed by this machine typically include high-precision glass and ceramic components, such as those used in optical lenses, electronic components, or automotive parts.

Machine Specifications:

| Item | Technical Parameters |

| Model | C Series |

| Laser Power | 20W / 30W / 60W |

| Laser Wavelength | Infrared / Green / Ultraviolet (Optional) |

| Pulse Width | Nanosecond / Picosecond / Femtosecond (Optional) |

| Laser Lifetime | ≥ 20,000 hours |

| Repeat Positioning Accuracy | ≤ ±2μm |

| Minimum Line Width | 20μm |

| Edge Collapse | < 5μm |

| Maximum Platform Speed | 1200mm/s |

| Maximum Platform Acceleration | 12,000mm/s |

| Control System Software | Laser Studio 8 (Integrated vision, laser, and motion) |

| Supported File Formats | DXF, Gerber, G-code, and other common formats |

| Environmental Requirements | Temperature: 22°C~25°C, Humidity: < 55% |

| Power Requirement | 380V 50Hz, about 6KVA |

Advantages:

Precision Cutting: With minimal thermal influence, the laser ensures clean edges and accurate cuts, even on delicate materials.

Fast and Efficient: The high-speed, high-precision linear motors, along with the automatic loading and unloading system, allow for rapid production and reduced downtime.

Long Machine Life: The laser has a long operational lifetime of over 20,000 hours, offering durability and reliability for continuous production.

Versatility: The machine can process different types of glass and brittle materials, making it versatile for use in various industries.

Applications in Various Industries:

Electronics:

Cutting optical glass, lens covers, and camera lenses used in smartphones, cameras, and displays.

Automotive:

Medical Devices:

Optical Industry: