Introduction:

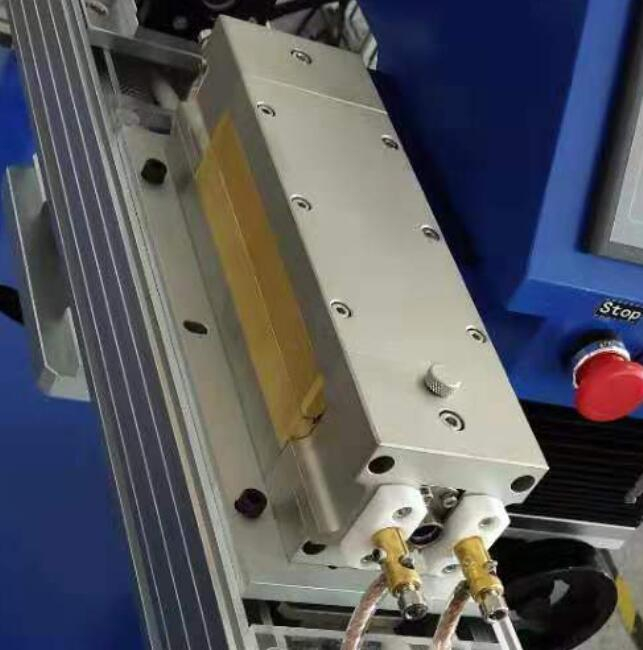

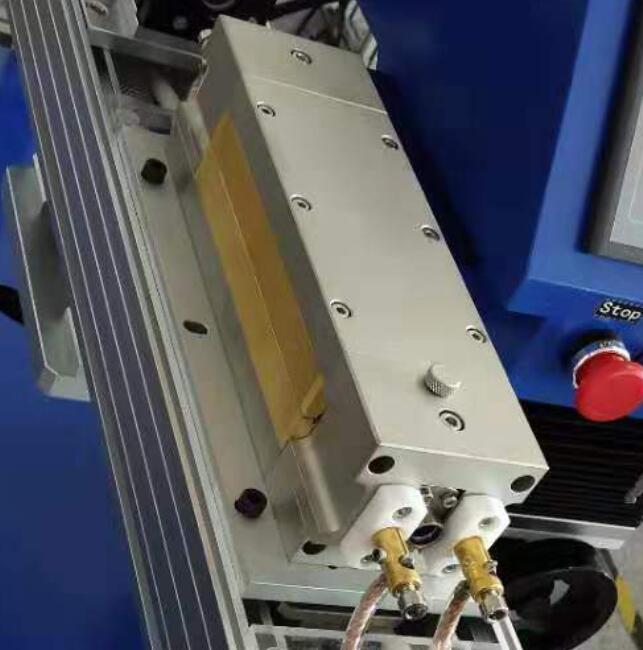

The function of the gold-plated concentrating cavity is to effectively couple the pump source with the working substance, thereby affecting the uniformity, divergence and optical distortion of the output beam. The concentrating cavity has two functions: one is to effectively couple the pump source with the working substance; the other is to determine the distribution of the pumping optical density on the laser material, thereby affecting the uniformity, divergence and optical distortion of the output beam. . Both the working substance and the pump source are installed in the concentrating cavity, so the advantages and disadvantages of the concentrating cavity directly affect the efficiency and working performance of the pump.

Features:

The solid-laser combined concentrating cavity has the advantages of good laser mode, uniform pumping, high concentrating efficiency, good cooling effect, reliability and durability, and long-term use efficiency, and is widely used in the manufacture of medium and small power pulsed and continuous lasers.

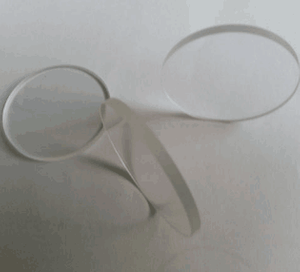

1) The concentrating cavity is composed of two parts of the upper and lower cavities. The upper and lower cavities are each an independent whole, which can be opened and closed freely. Only the upper cavity can be uncovered when the lamp is replaced or replaced. It is possible to carry out lamp installation and lamp replacement without removing the other optical path components of the laser or the entire concentrating cavity, without re-adjusting and debugging the light; uncovering the upper cavity during the installation of the crystal can conveniently observe the installation of the crystal. It is convenient to adjust the position of the crystal. In this case, it is also convenient to observe and debug the visible light source. It has the characteristics of convenient installation, accurate positioning and simple operation.

2) The geometric parameters of the reflecting surface of the concentrating cavity are close to the theoretical value, the mirror gold plating is fine and uniform, the concentrating effect is good, and the conversion efficiency is high.

3) The concentrating cavity cooling is to first cool the crystal and then cool the reflecting cavity and the pump lamp, which can effectively protect the crystal, extend the life of the crystal and have a good cooling effect.