Gold silver copper optical glass frame electricity Jewelry Laser Welding Machine--DP-ND200W Large Microscope

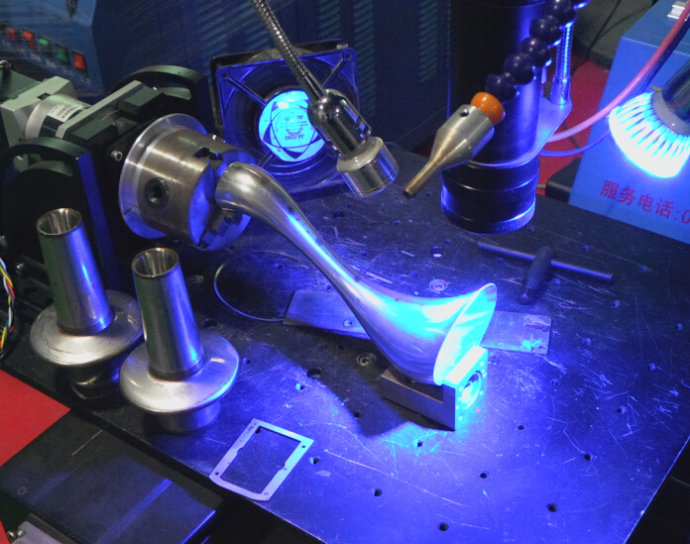

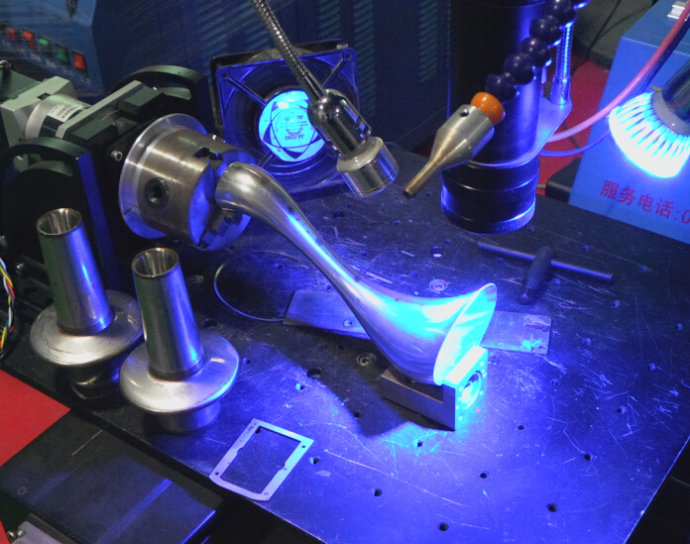

Jewelry laser spot welding machine is suitable for gold jewelry laser welding, silver jewelry laser welding, titanium alloy jewelry laser spot welding processing, stainless steel jewelry laser welding, various jewelry laser spot welding, and manual laser welding of small metal parts.

Machine parameters:

Machine model | DP-ND200W |

Max laser power | 200w |

Laser wavelength | 1064nm |

Max power of single impulse | 80J |

Welding depth | 0.1-2.5mm |

Pulse width | 0.1-20ms |

Laser welding frequency | 0-50Hz |

Adjustable scope of laser spot | 0.1-2.0mm |

Power Consumption | ≤6KW |

Cooling system dimensions | Water cooling |

Observation system | 10X Microscope or HD CCD |

Power required | 220V±10%/50Hz |

Consumable | Xenon lamp,Filter element,Protective lens,Argon |

Working temperature | 55°F(13°C)-82°F(28°C) |

Working Humidity | 5%-75%

|

Machine Features:

1. The ergonomic design of the whole machine is suitable for the jewelry laser welding industry, professional appearance design, the core components are imported with original packaging, and the performance is stable, suitable for the needs of long-term continuous work;

2. Since the operator needs to observe the microscope all the time and is always in one position, this laser spot welding machine specially adds head cushion and arm support, so that there is no arm and neck pain during long-term operation;

3. The internal space is large, which is convenient for the placement of laser spot welding tools and fixtures;

4. The working area is equipped with an electric focusing device, and the laser spot welding parameters are adjusted and turned on, making it easier to use;

5. Adjustable and high-brightness LED ring shadowless lamp can observe the workpiece without shadows. With the high-definition type parallel light path microscope, the laser welding position can be observed more clearly;

6. High magnification beam expansion system to obtain finer light spots and meet the needs of fine laser spot welding;

7. Energy, pulse width, frequency, spot size, etc. can be adjusted in a wide range, and various welding effects can be achieved. The parameters are adjusted by the control rod in the closed cavity, which is simple and efficient;