Versatile Material Processing: Capable of handling various materials, including steel, stainless steel, and aluminum.

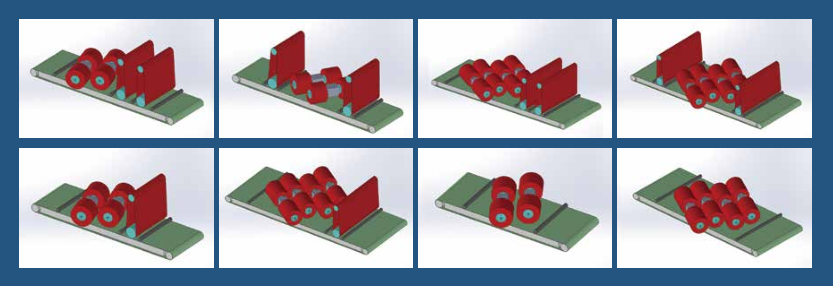

Simultaneous Thickness Processing: Supports the processing of different material thicknesses (E-units).

Customizable Parameters: Individually adjustable processing settings for optimal results.

Even Processing: Thoughtful rotary head design ensures consistent results across the entire working width.

Maximum Tool Contact: Achieves perfect edge rounding up to a 2 mm radius.

Efficient for Small Parts: Processes small parts (down to 50x50 mm) regardless of geometry.

Ergonomic Design: Stationary machine table with constant height for comfortable operation.

User-Friendly Interface: Intuitive touch panel for easy operation.

Energy Efficiency: Processing units can be independently turned on/off for flexibility.

Quick Setup: Automatic positioning of tool axes for fast machine setting.

Program Memory: Ensures automatic settings for reproducible results.

Rapid Tool Change: Fast tool-changing system minimizes setup time.

Accessibility: Optimal machine access for easy cleaning and maintenance.

Monitoring Window: Allows process observation through machine doors.

Customization Options: Tailored features to meet individual customer requirements.

Automation Ready: Possibility for integration into production lines.

Bäumer Group - Known for their innovative deburring and finishing solutions for various industries.

Timesavers - Specializes in surface finishing and deburring machines, offering a wide range of solutions for metal processing.

Glebar Company - Provides advanced grinding solutions, including for deburring applications in different materials.

Apex Machine Group - Offers a variety of deburring and finishing machines tailored for different manufacturing needs.

Dürr Ecoclean - Focuses on cleaning and surface finishing technologies, including grinding and deburring machines.

Suhner Group - Known for their versatile grinding and deburring systems, suitable for a range of applications.

Kuhlmeyer - Specializes in grinding and deburring machines for sheet metal and other materials.

Scantool Group - Offers a range of grinding and deburring machines for industrial use.

Wikus - Known for their band saw blades and associated grinding and deburring equipment.

Lissmac - Provides innovative deburring and edge rounding solutions for various materials.