MK-400PLUS

High-Precision 5-Axis CNC Grinding Center for Indexable Insert Periphery Grinding

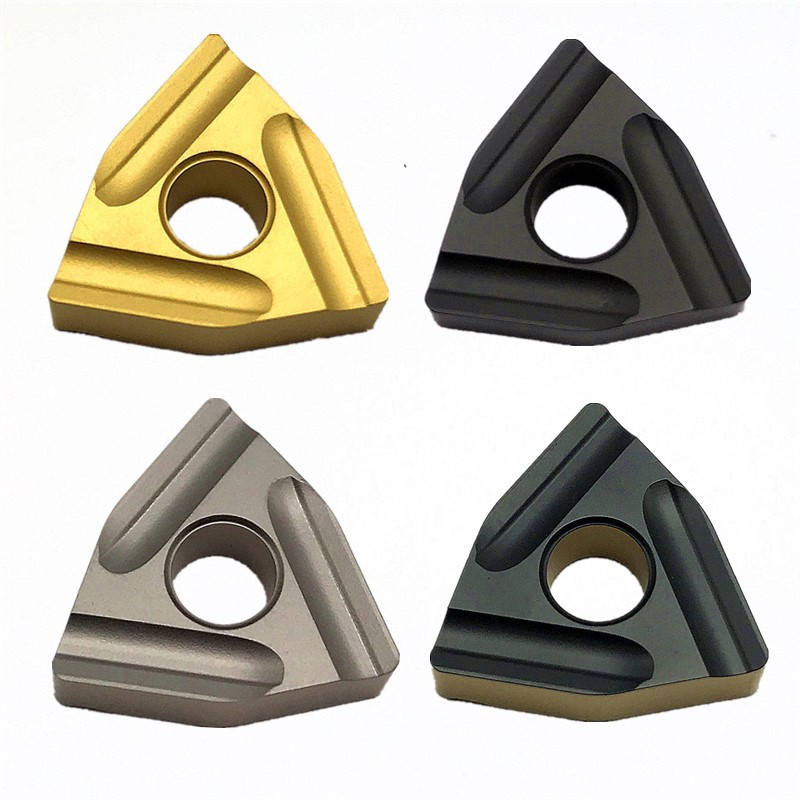

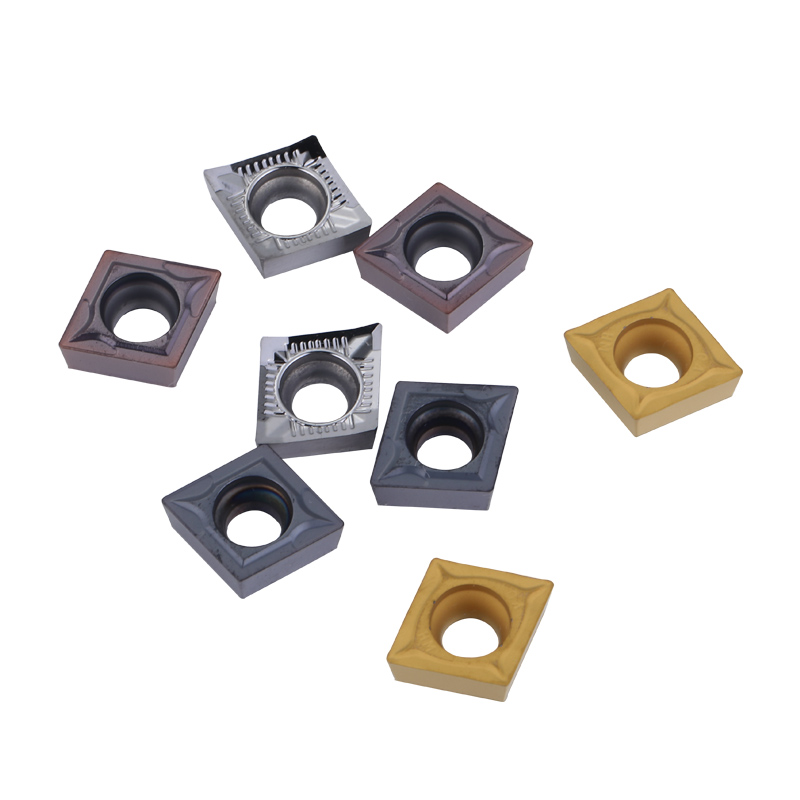

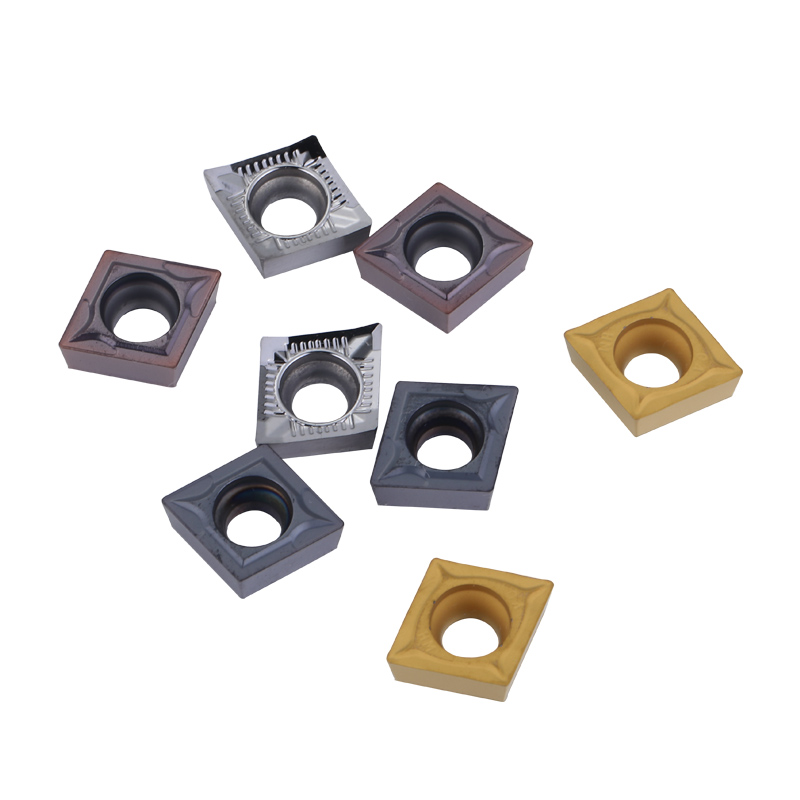

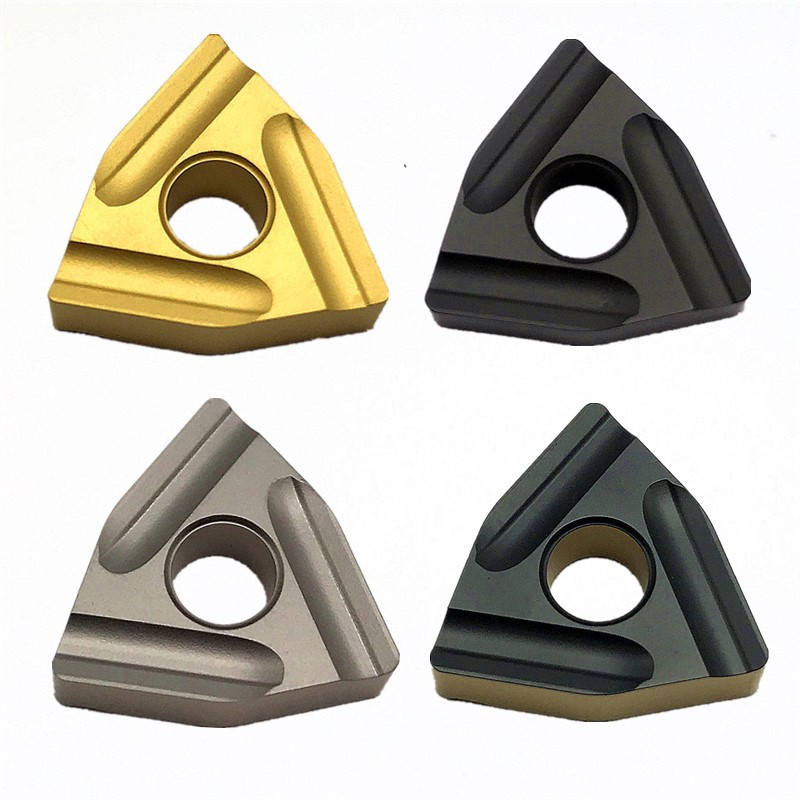

Designed for: Carbide, Cermet, Ceramic, CBN, PCD Inserts

Grinding Wheel Diameter: Ø 400 mm

✅ Product Overview

The MK-400PLUS is a state-of-the-art 5-axis CNC grinding machine engineered specifically for high-precision peripheral grinding and double chamfering of indexable inserts. With a robust and rigid mechanical design, advanced automation features, and user-friendly CNC interface, the MK-400PLUS sets a new standard for efficient, consistent, and flexible grinding of various cutting tool materials including carbide, cermet, ceramics, CBN, and even PCD.

It supports processing of standard, small-diameter, and large-diameter inserts with high accuracy and short changeover time, making it ideal for both mass production and complex tool geometries.

️ Applications

Periphery grinding of indexable inserts with tight tolerance

Single and double chamfer grinding

Complex edge geometries for turning, milling, and grooving inserts

Automatic correction and regrinding

Applicable to insert materials including:

Technical Specifications

| Feature | Details |

| Processing Object | Standard indexable insert periphery grinding, double chamfering |

| Materials | Carbide, Cermet, Ceramic, CBN, PCD |

| Min. Inscribed Circle | Equilateral Triangle: 3.5 mm; Other Shapes: 4.7 mm |

| Max. Circumscribed Circle | 45 mm |

| Max. Thickness | 15 mm (up to 3 pcs x 4.76 mm at once) |

⚙️ Axis System & Motion Control

| Axis | Function |

| X-Axis | Left-right oscillation (direct-drive, auto lubrication) |

| Y-Axis | In-feed (direct-drive, auto lubrication) |

| A-Axis | Workpiece rotation, blade seat projection: 36 mm |

| C-Axis | Workpiece table angle adjustment (-90° to +90°) |

| V-Axis | Online wheel cleaning |

| W-Axis | Manual core positioning |

Spindle & Dressing

| Component | Specification |

| Main Spindle | 7.5 kW flange-type 3-phase induction motor (V3 grade) |

| Dressing Spindle | 1.5 kW electric spindle for wheel dressing |

Positioning & Detection System

Core Positioning: Center hole alignment (insert left side)

Fine Positioning: Manual front/back, automatic up/down

Measuring System:

Positioning Capacity: 1 block

Automation & Handling

| Feature | Details |

| Robotic Arm | 3-axis linear coordinate arm |

| Axis Control | B1: Tray left-right; B2: Tray in/out; B3: Up/down |

| Tray System | 2 × Standard Trays (350 × 350 mm), 2 × T-Type Trays (190 × 370 mm) |

| Gripper | 1 gripper (supply/unload) |

CNC Control System

Control Unit: Built-in CNC (No external PC required)

Controlled Axes: X, Y, A, C, V, W

Simultaneous Axis Control: Up to 9 axes

Programming: Dialog-based intuitive programming interface for easy setup and fast changeover

⚡ Utility Requirements & Dimensions

| Item | Specification |

| Power Supply | 25 kVA, AC 380V, 50–60 Hz |

| Compressed Air | ≥ 0.5 MPa, 250 N/min |

| Hydraulic Pressure | Max. 7 MPa |

| Machine Dimensions | 2,475 mm (W) × 2,250 mm (D) × 2,160 mm (H) |

| Net Weight | 5,500 kg |