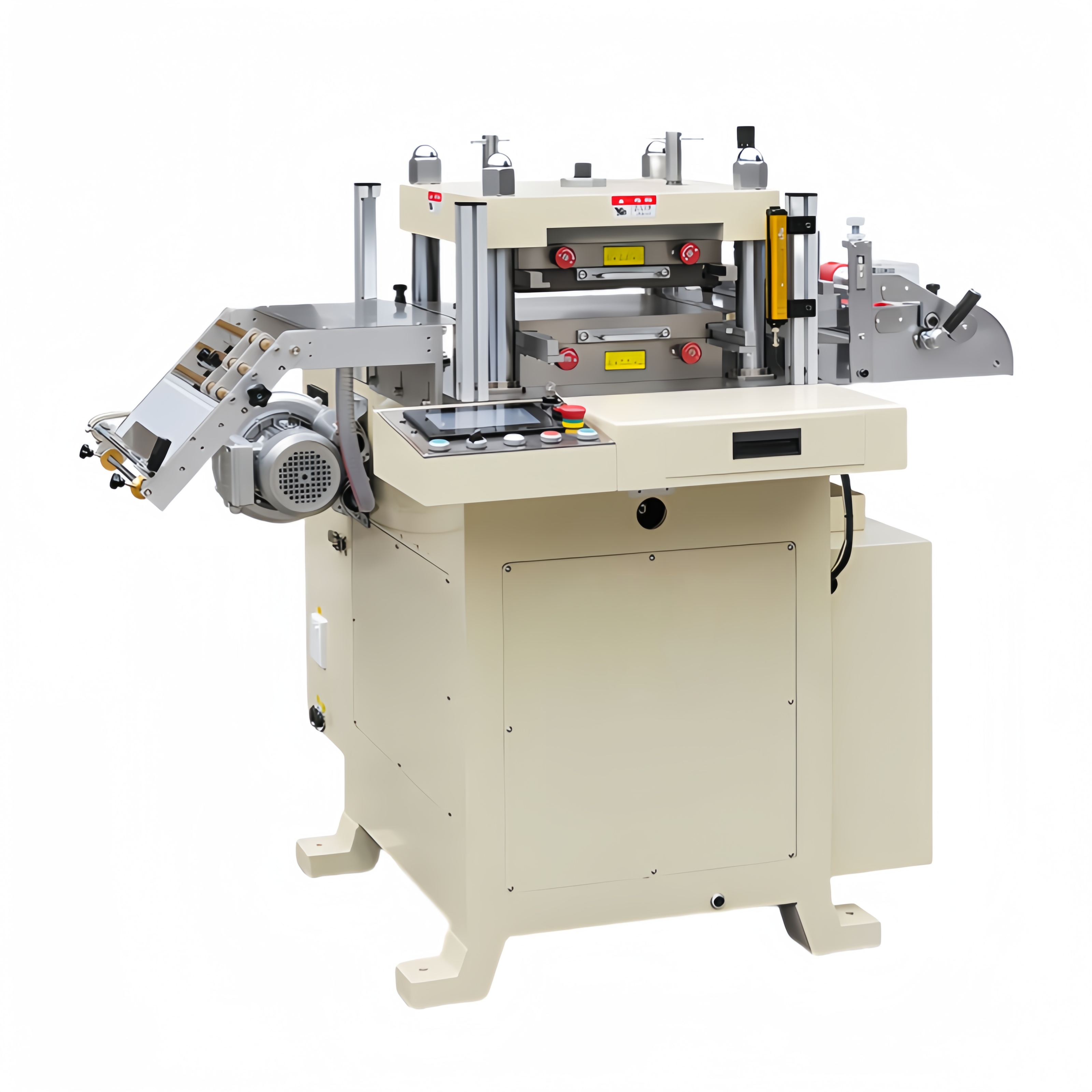

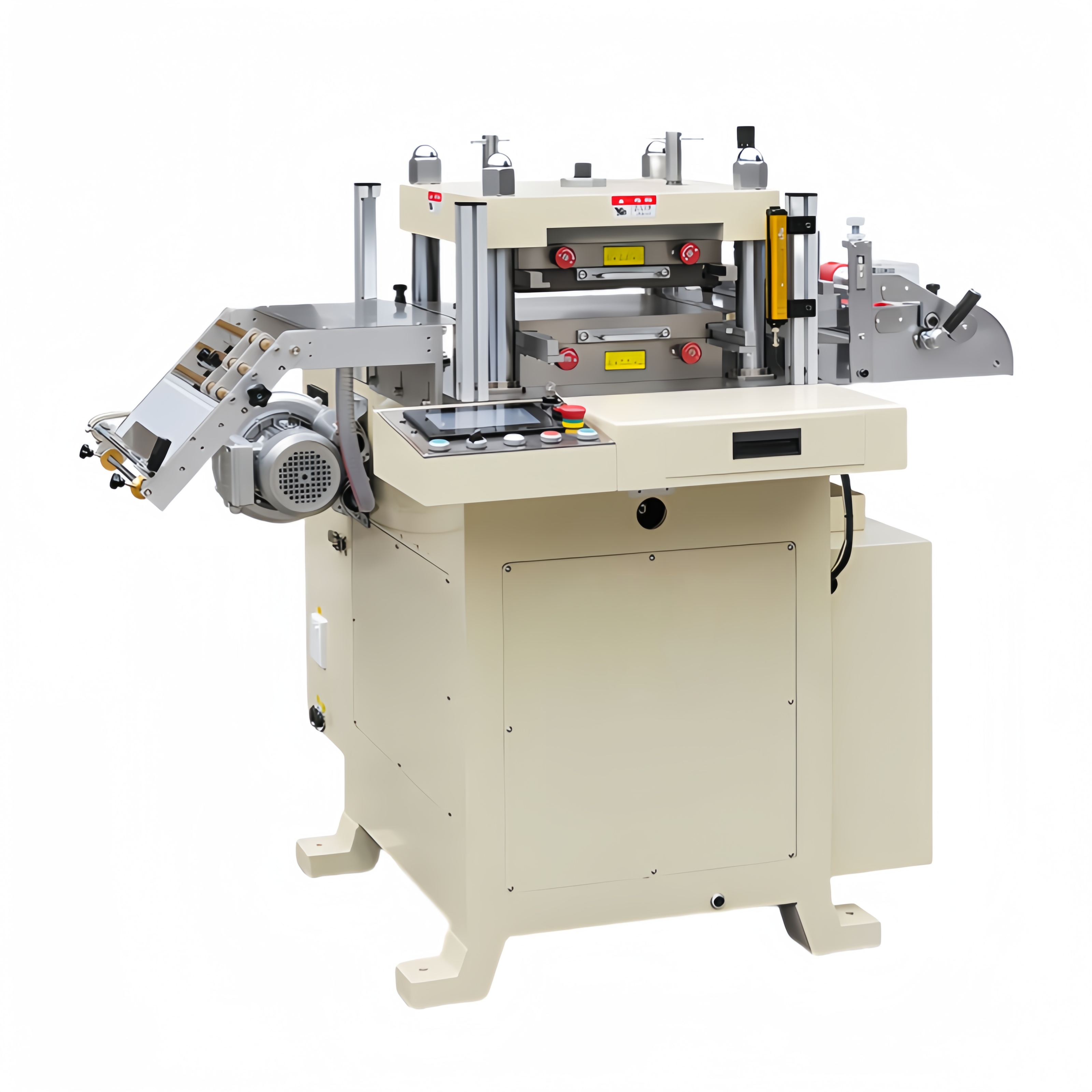

JT-D300/350/450 high precision positioning die cutting machine.

A high precision positioning die cutting machine is specialized equipment used for precise die-cutting applications, typically employed in industries requiring highly accurate die cutting, such as electronics, labels, films, and more. Its key feature is its ability to achieve high precision in positioning, ensuring accurate alignment during multiple die-cutting operations, thereby minimizing errors.

Main Features of the High Precision Positioning Die Cutting Machine:

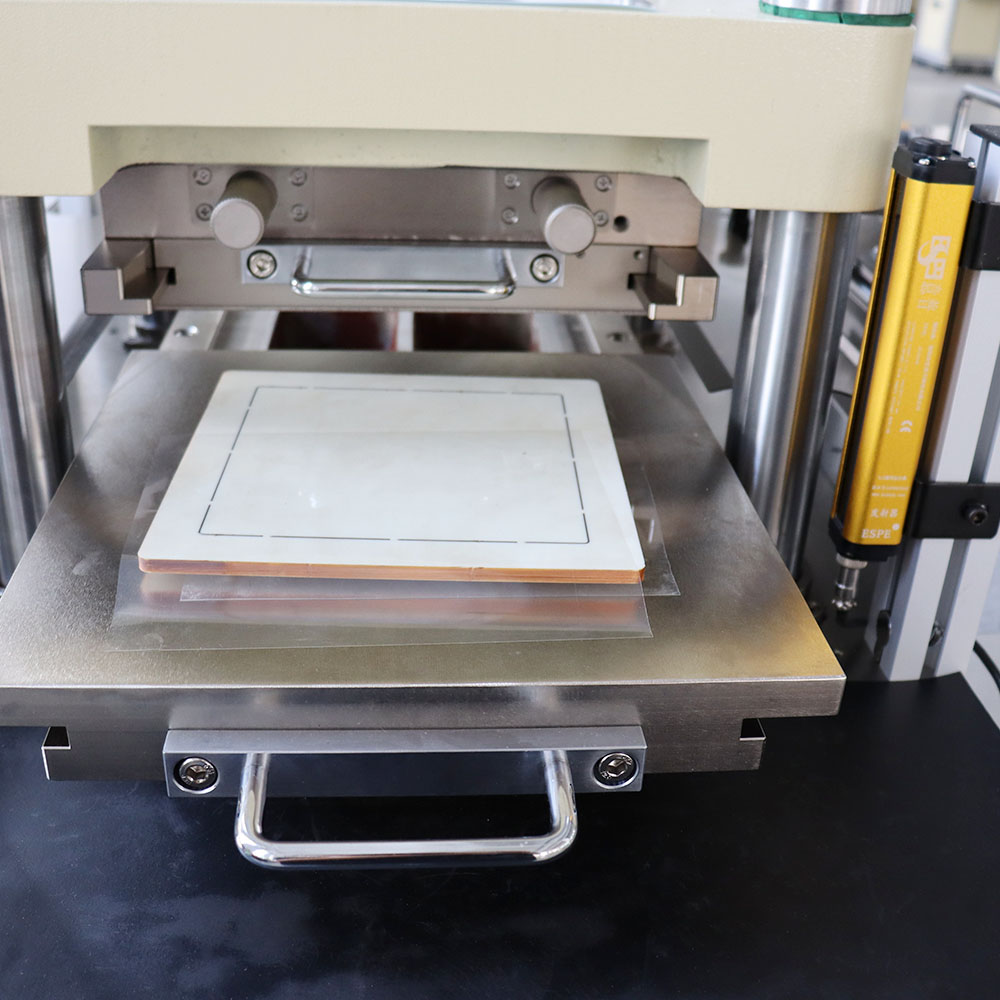

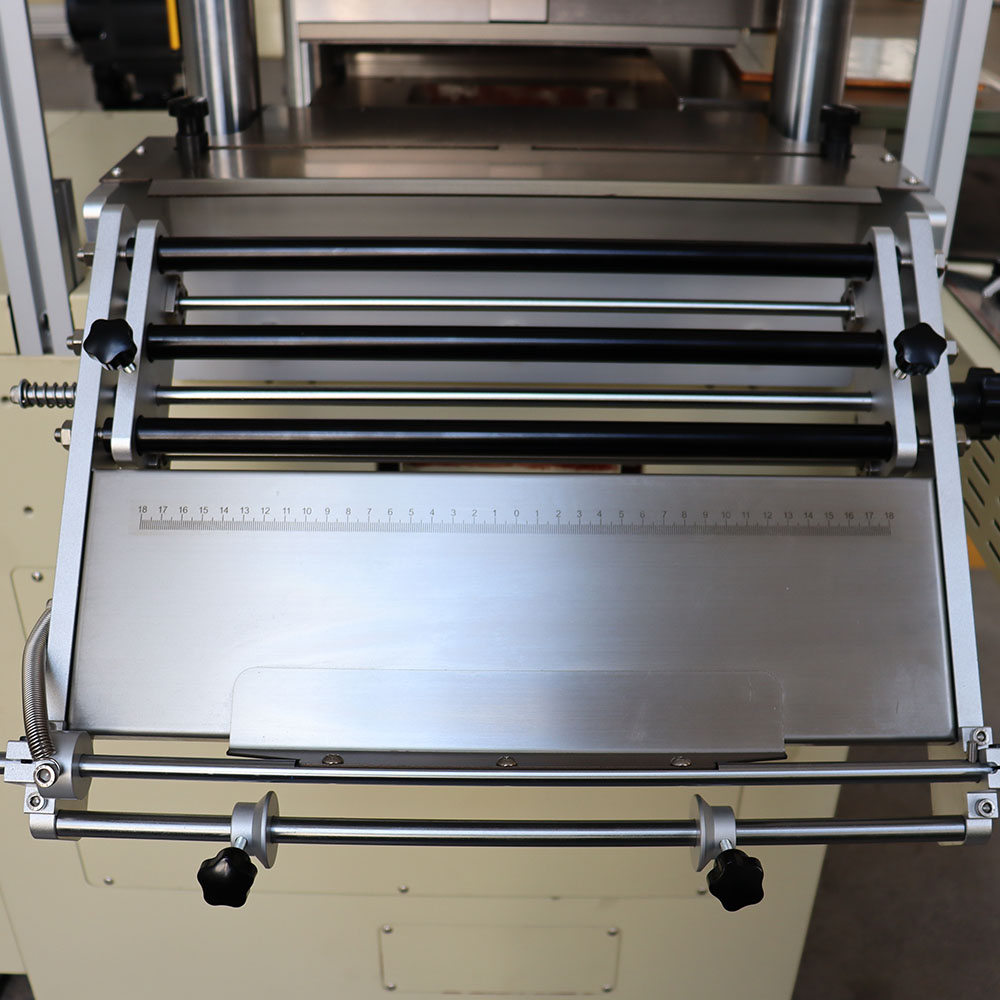

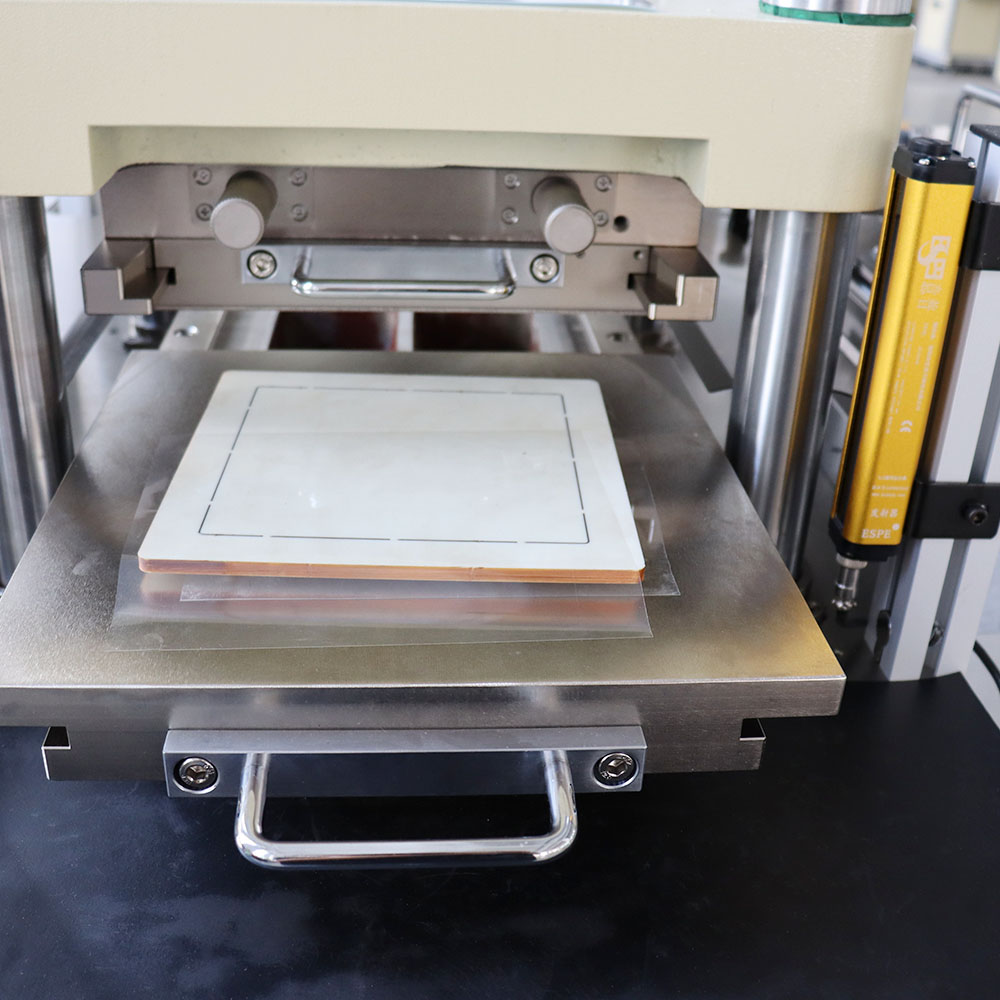

High-Precision Positioning: Utilizes small hole positioning or a vision system to ensure cutting precision for each operation, avoiding misalignment.

Stable Pressure Control: Typically equipped with dual servo drives to provide stable pressure control, ensuring uniform pressure during die-cutting and reducing material damage.

Low Noise Operation: The machine operates with low noise, making it suitable for environments where quiet operation is required.

Quick Adjustment: Parameters like voltage and pressure can be quickly adjusted via a digital display, simplifying the operation process.

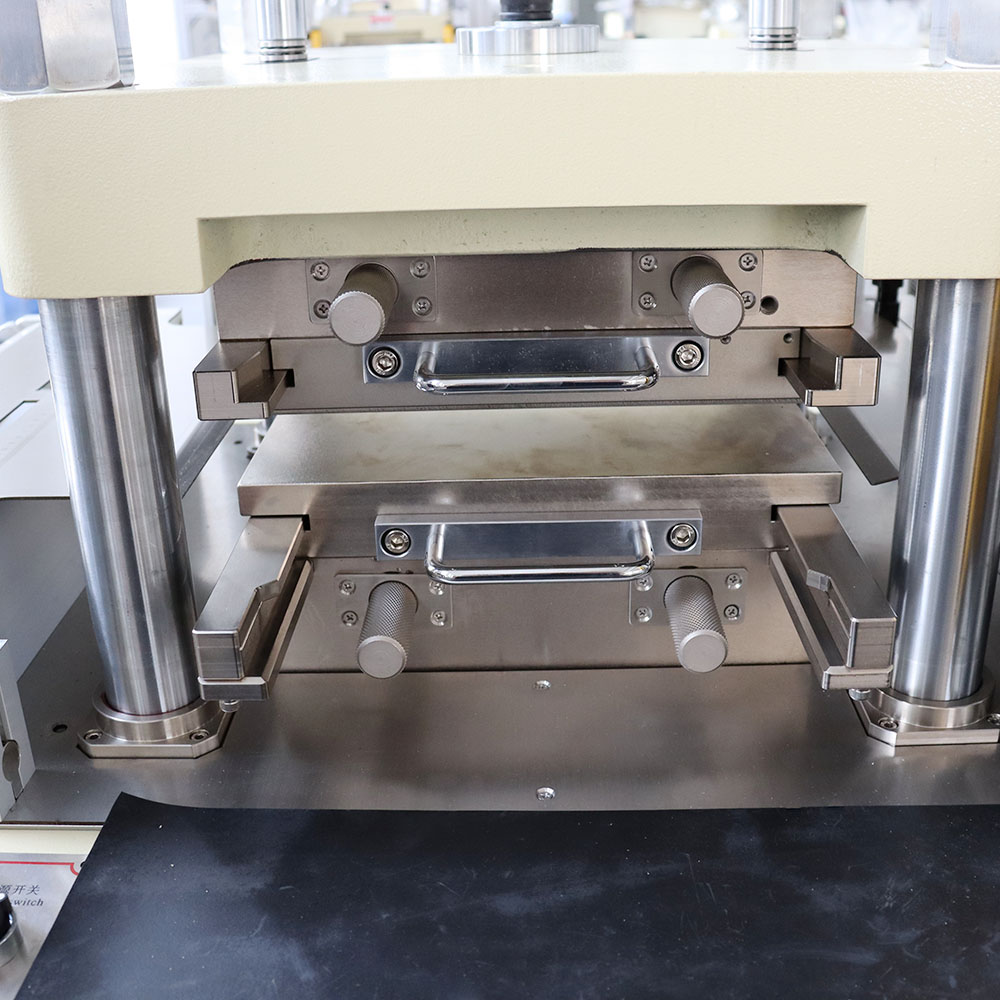

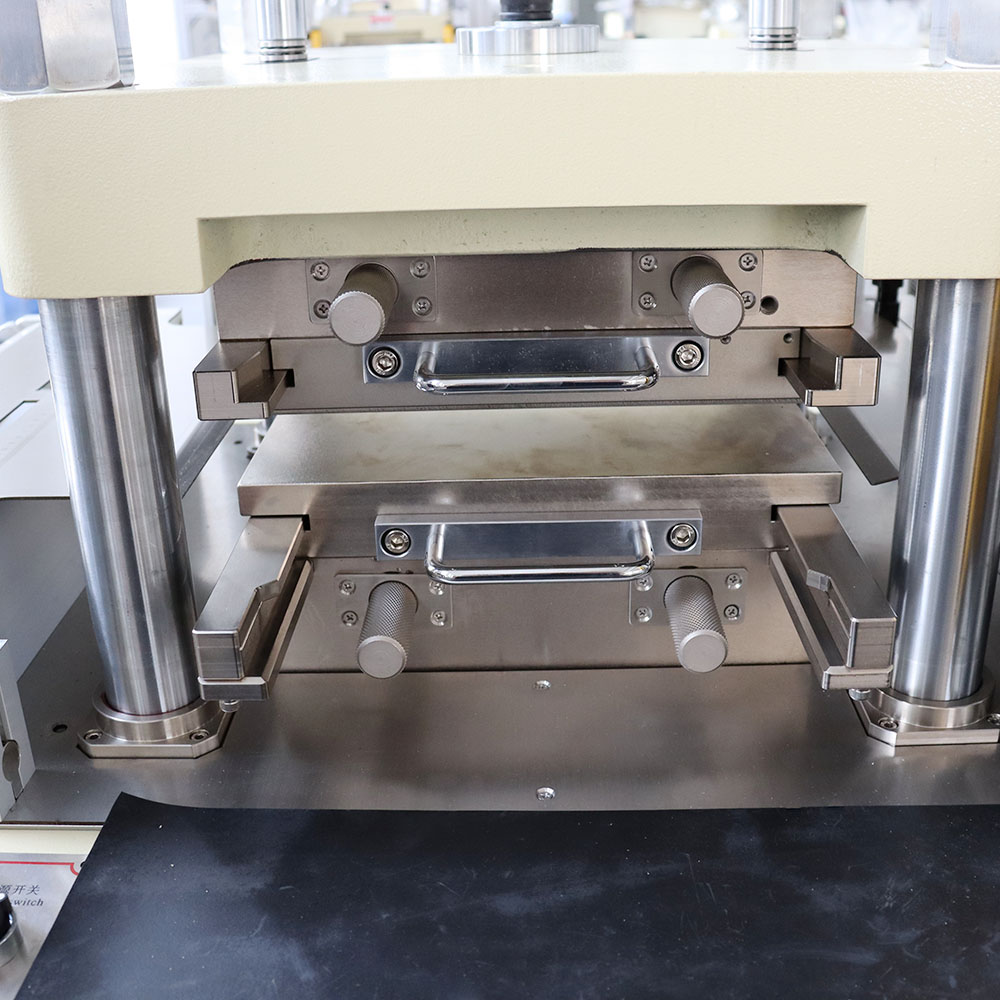

Quick Die Change Function: Some high precision die-cutting machines are equipped with a Quick Die Change (QDC) system, allowing for fast switching between multiple dies, enhancing production efficiency.

Wide Range of Applications: It can accommodate various types of dies, including hardware molds, engraving molds, corrosion molds, plywood molds, and wooden molds.

Application Scenarios:

Electronics: For applications requiring high-precision die-cutting, such as smartphone films and electronic labels.

Packaging Industry: For accurate cutting of labels, stickers, and similar products.

Other High-Precision Processing Needs: Such as decorative materials, films, tapes, and more.

The high precision positioning die cutting machine offers the advantage of efficient operation and stable processing quality, meeting modern industrial demands for precision machining and high productivity.

Key Performance Characteristics:

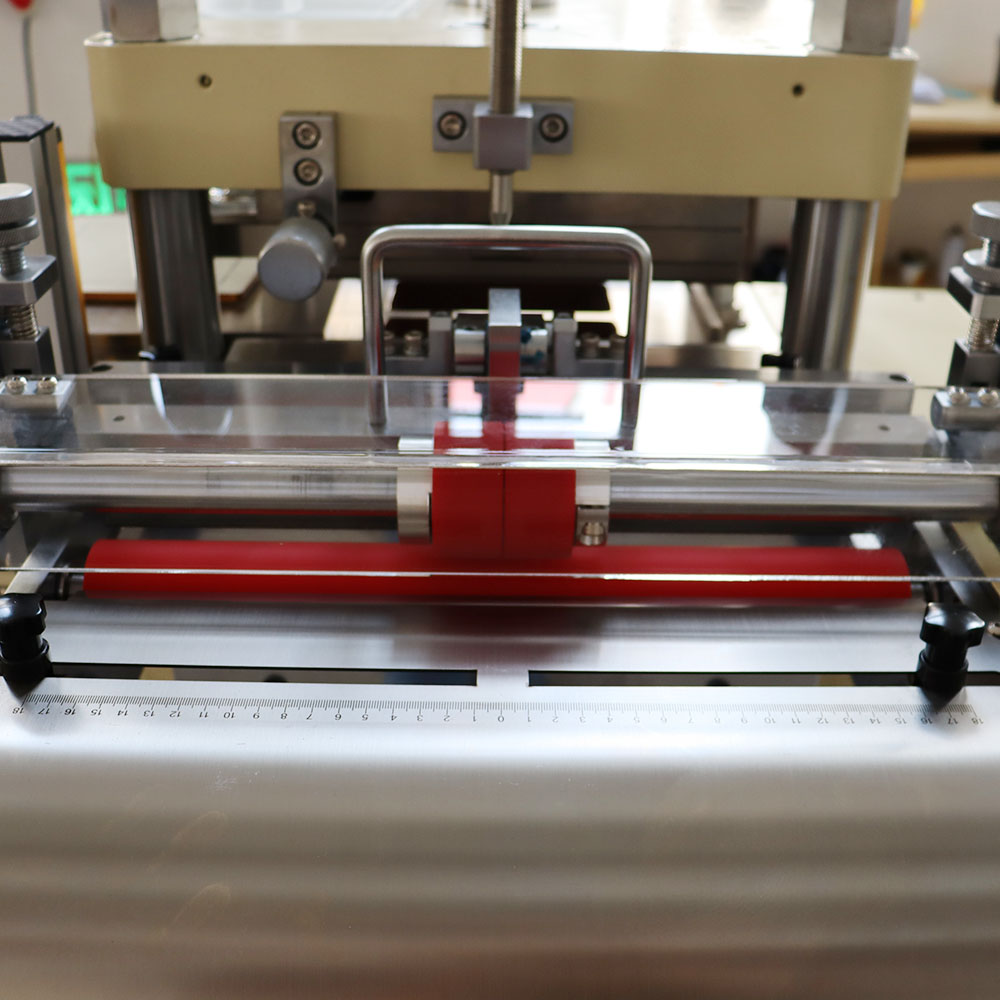

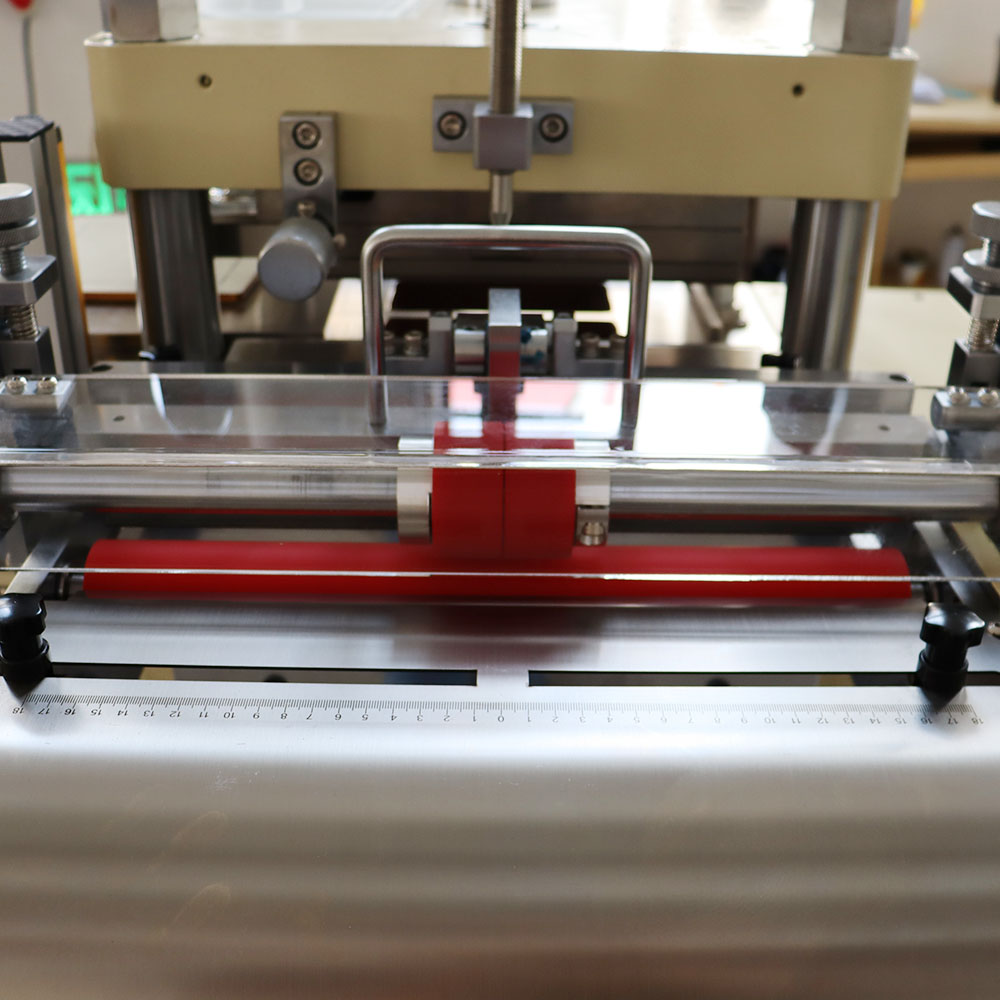

Instant Correction Device: Small hole positioning for immediate correction.

Stable Pressure: Double servo drive, ensures no noise and precise control.

Easy Voltage Adjustment: Electric digital display for quick voltage adjustment.

Strong Punching Force: Offers stable die-cutting pressure.

QDC Mold Compatibility: Supports multi-high precision nesting die cutting.

Specifications for JT-D300/350/450:

| ITEM | Unit | JT-D300 | JT-D350 | JT-D450 |

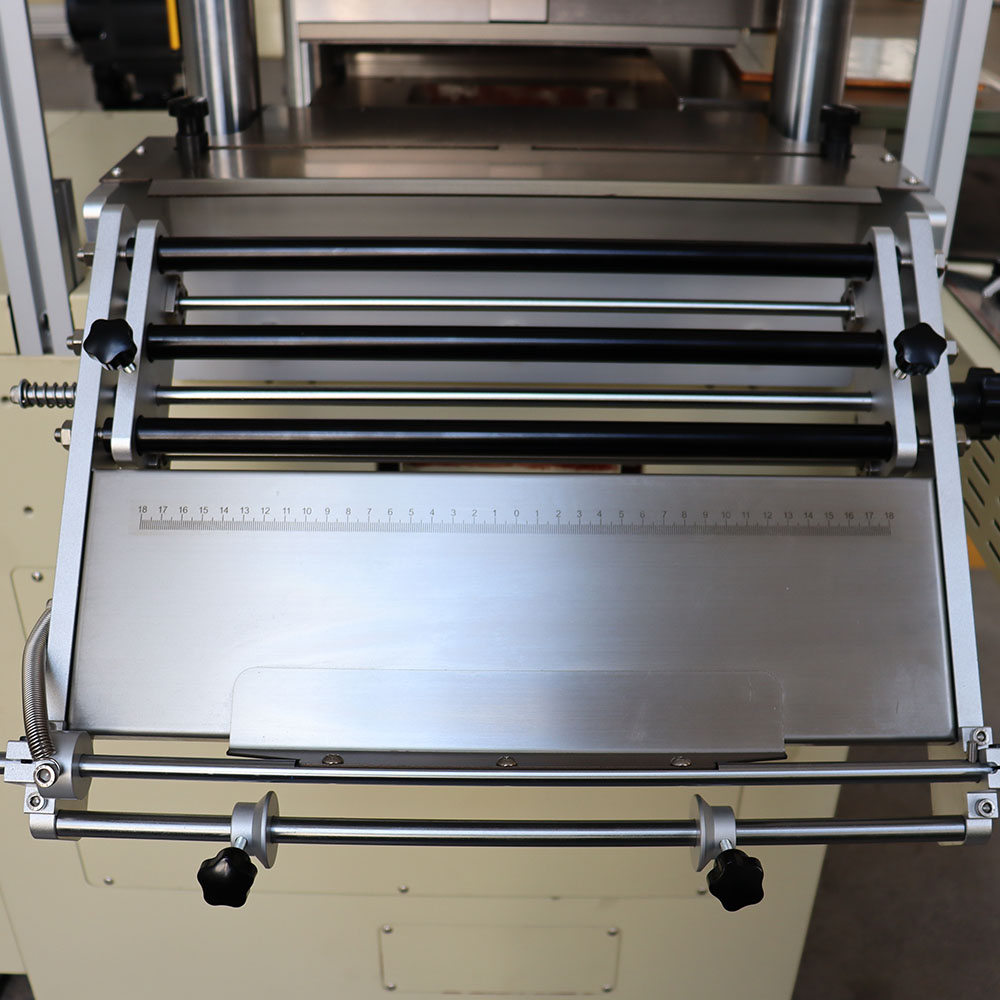

| Feed width | mm | 310 | 370 | 470 |

| Max. die cutting area (L × W) | mm | 300 × 310 | 350 × 370 | 450 × 470 |

| Max. operating speed | times/hr | 18000 | 18000 | 18000 |

| Max. blanking size (L × W) | mm | 180 × 180 | 200 × 200 | 107 × 280 |

| Punching stroke | mm | 30 | 28 | 28 |

| Pressure regulation | mm | 30 | 30 | 30 |

| Voltage regulation accuracy | mm | ±0.05 | ±0.05 | ±0.05 |

| Drawing accuracy | mm | ±0.05 | ±0.05 | ±0.05 |

| Upper form size (L × W × H) | mm | 300 × 310 × 37 | 350 × 370 × 37 | 450 × 470 × 37 |

| Lower template size (L × W) | mm | 300 × 310 × 45 | 350 × 370 × 45 | 450 × 470 × 45 |

| Overall dimension (L × W × H) | mm | 1500 × 1350 × 1350 | 1550 × 1400 × 1400 | 1700 × 1450 × 1450 |

| Machine weight | Kg | 700 | 900 | 1000 |

| Air source specification | Mpa | 0.5~0.7 | 0.5~0.7 | 0.5~0.7 |

| Total power | KW | 5 | 7.5 | 7.5 |

| Lubrication mode |

| Automatic lubrication | Automatic lubrication | Automatic lubrication |

| Applicable die |

| Hardware mold, carving mold, corrosion mold, plywood mold, wood mold |

|

|

This machine is particularly suitable for cutting various molds and ensures high accuracy in pressure and voltage regulation for precise die-cutting applications.