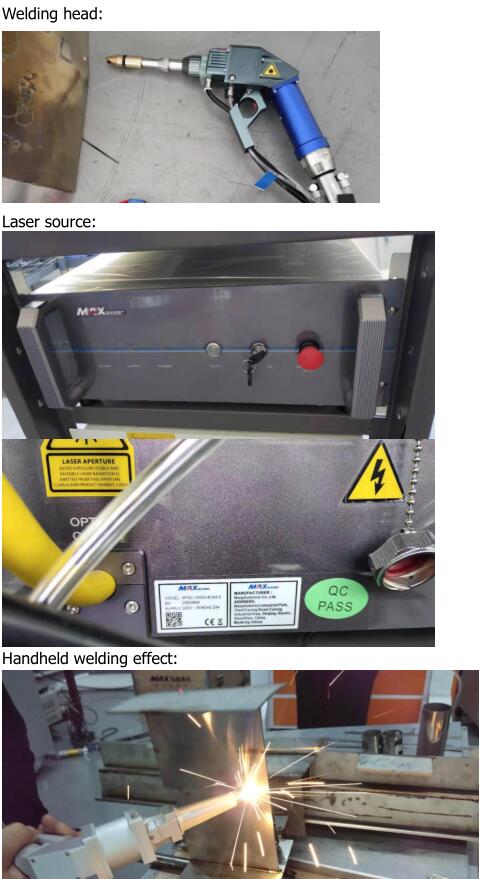

1.The weld seam is smooth and beautiful,

the welding workpiece has no deformation, the welding is firm, and no subsequent grinding process is required, which saves time and cost.

Fast welding speed, 2~10 times faster than traditional welding.

2.Easy operating need no training

welding seam beautiful smooth and beautiful, don’t need polish, save your time

No deformation or welding scar, firm welding of the workpiece.

3.Easy Maintance

Laser welding has less consumables and long service life.Safer, more environmentally friendly.

Application Industries:

Machine shell sheet metal welding,Kitchen cabinets,staircase elevator,Food Machinery,shelf, oven,stainless steel door,window guardrail,distribution box,medical equipment,communications equipment,craft gifts,household and other industries.

Application Materials:

Stainless steel, copper, aluminum, gold, chromium, silver, titanium, nickel and other metals or alloys, it can also be used for a variety of welding between different materials.

Handheld laser welding machine in customer workshop https://youtu.be/cGhemuw8Pe8