Laser Cut Sheet Metal Deburring and Finishing Machine

For metal deburring, edge conditioning, finishing, and laser oxide removal, a specialized machine can achieve all these processes in a single pass. This type of machine is designed to handle multiple tasks efficiently, particularly with materials processed by laser cutting, which often leave sharp edges, oxide layers, and require smooth finishing.

Main Technical Parameters of the Equipment

| Main Technical Parameters of the Equipment | Specifications |

| Processing Width | ≤800mm |

| Processing Thickness | 0.5~80mm |

| Minimum Processing Size | 50mm × 50mm (without holes) |

| Total Power | 30.25KW (excluding dust collection) |

| Sanding Belt Size | Φ1910mm × 800mm |

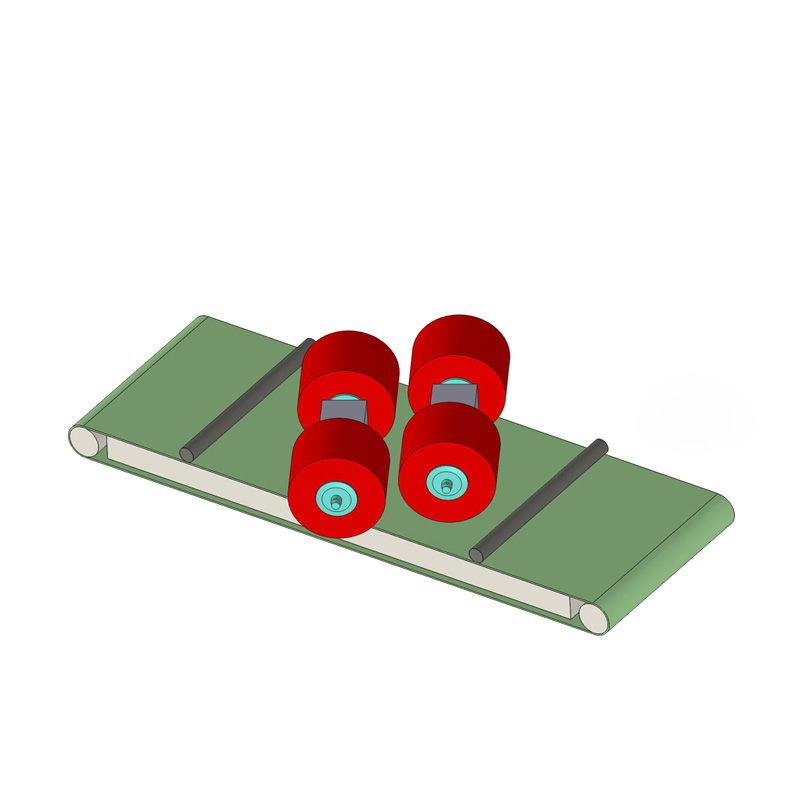

| Sanding Disc Roller Brush Size | Φ300mm × 300mm |

| Conveyor Speed | 0.5~6m/min (variable frequency adjustable) |

| Sanding Belt Linear Speed | Approximately 18m/s |

| Roll Brush Self-Rotation Speed | 8~26m/s (variable frequency adjustable) |

| Roll Brush Orbit Speed | 1~15r/min (variable frequency adjustable) |

| Number of Roll Brush Planetary Rotation Axes | 1 |

| Number of Roll Brush Planetary Self-Rotation Axes | 4 |

| Processing Thickness Servo Adjustment Precision | 0.01mm |

| Roll Brush Compensation Servo Adjustment Precision | 0.01mm |

| Grinding Consumables | Roller brush |

| Dust Collection Air Volume | 4000m³/h |

| Equipment Dimensions | Length 2650mm × Width 1650mm × Height 2150mm |

| Total Weight | Approximately 2.2T |

Metal Deburring and Finishing Machine

This high-performance machine is engineered to process metal sheets and parts through deburring, edge conditioning, finishing, and laser oxide removal in a streamlined, single-pass operation.

Core Features

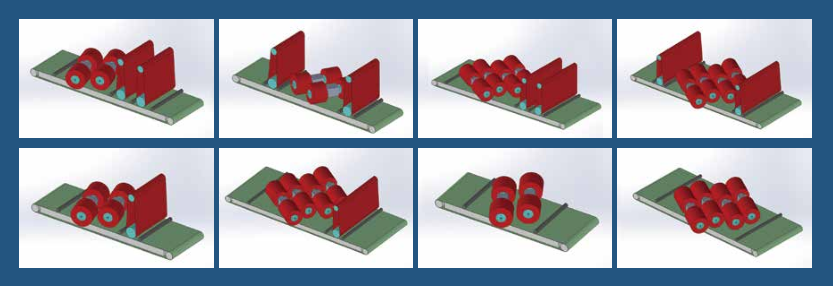

Multi-Head System:

2-3 Head Configurations: Common head setups include Drum/Top Brush/Drum or Drum/Top Brush to allow flexibility based on finishing requirements.

Abrasive Belt and Barrel Brush Combination: Equipped with an abrasive belt for initial deburring, followed by a brush head to smooth edges, condition the surface, and remove oxide layers.

Oxide Removal:

Designed specifically for laser oxide removal, which ensures a clean edge and surface free from oxidation—a key requirement for preparing parts for welding, coating, or painting.

Edge Rounding: Achieves smooth, rounded edges on cut metal parts, which enhances safety, durability, and aesthetic quality.

Precision Tracking System:

Electronic Photo-Eye Belt Tracking: Maintains precise belt alignment to extend belt life and ensure consistent finishing across parts.

Dust Extraction System: An integrated dust extraction system removes particulates, including metal dust and oxide particles, for a clean work environment.

Compact and Space-Efficient:

Small Footprint Design: Optimized for facilities with limited space, ensuring that high production capacity is achievable without requiring extensive floor space.

High Production Capacity:

Continuous Operation: Allows for multi-shift operation, increasing throughput and reducing downtime.

Reduced Operating Costs: Efficient deburring and finishing processes contribute to reduced costs, with faster processing and fewer consumables needed.

Dry Operation:

Dry Process eliminates the need for coolant or water, reducing maintenance and operational expenses while making it more environmentally friendly.

Versatile Applications:

Processes a range of cut and stamped parts, including laser, plasma, and water-jet cut materials, allowing flexibility in application across metal fabrication processes.

Deburring:

Abrasive Belt Head: Removes heavy burrs and slag left from cutting processes like laser, plasma, stamping, and punching.

Rotary Brush Heads: Smooth out smaller burrs and refine edges for a safer, cleaner finish, which is especially useful for complex geometries or parts with internal cutouts.

Finishing:

Barrel Brush or Polishing Brush: Provides a uniform finish across the entire metal surface, enhancing appearance and creating a smooth texture.

Adjustable settings allow for varying degrees of surface roughness, from satin finishes to high polish, to meet different finishing requirements.

Edge Rounding:

Rotary or Planetary Brushes: Achieve smooth, rounded edges (small R arc effect) to enhance safety, corrosion resistance, and paint adhesion.

Ideal for parts where rounded edges are required, such as in automotive or appliance components.

Edge Breaking:

Drum or Brush Configurations: Specialized heads for breaking sharp edges, making them slightly beveled or chamfered to prevent injury and improve part durability.

Ensures consistent edge breaking without compromising part dimensions.

Oxide Skin Removal:

Oxide Removal Brushes or Scotch-Brite Heads: Remove oxide layers formed during laser cutting, crucial for weld-prep and paint-ready surfaces.

Ensures that metal parts have a clean, oxide-free surface for improved welding and coating quality.