Industrial deburring machines for metal finishing or deburring are essential in manufacturing, particularly for metal fabrication processes that involve laser cutting, stamping, shearing, and other methods that leave behind burrs or rough edges.

1. Types of Industrial Deburring Machines

Abrasive Belt Machines: These machines use abrasive belts to remove burrs and achieve a smooth surface finish. They are often adjustable in speed and pressure to handle a variety of metal types and thicknesses.

Rotary Brush Machines: Equipped with rotating brushes, these machines are ideal for edge rounding and finishing. They can remove oxide layers and fine burrs without affecting the underlying surface.

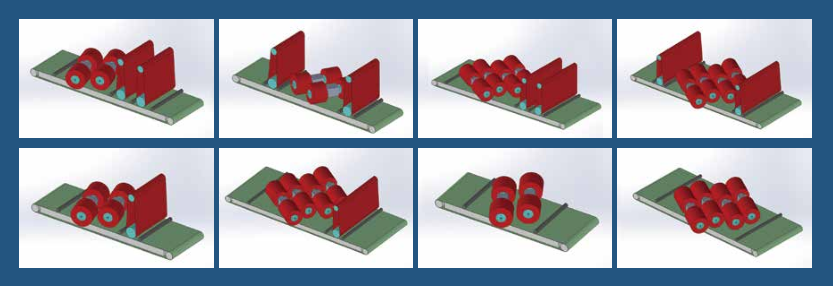

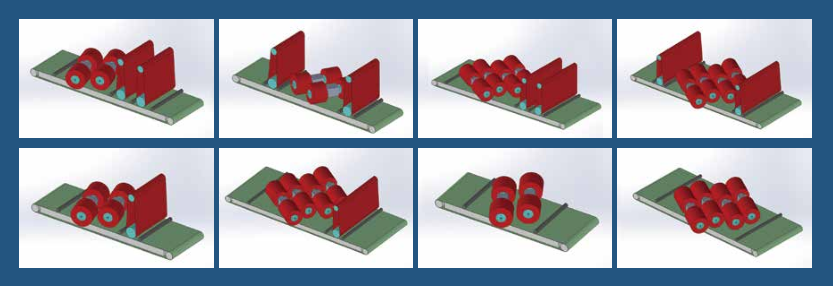

Planetary Head Machines: These machines use multiple heads or brushes that rotate in various directions, making them well-suited for edge rounding and polishing.

Barrel Brush Machines: Common in combination machines, these brushes work alongside abrasive belts for both deburring and finishing in one pass, ideal for laser-cut or punched metal sheets.

Water Grinding and Wet Deburring Machines: For applications where heat generation and dust control are concerns, water grinding systems use wet processes to remove burrs and polish.

2. Common Features

Adjustable Feed Rates and Motor Power: Many machines feature variable feed rates and motor power adjustments for different materials and levels of finishing required. High-power motors increase efficiency on tougher metals.

Dust Extraction and Vacuum Systems: Dust and particle management systems, including integrated dust extraction and vacuum beds, improve air quality and ensure safe operation.

Abrasive Belt and Brush Compatibility: Industrial deburring machines often support a variety of abrasive belts and brushes, from heavy-duty belts for slag removal to softer brushes for edge rounding.

Electronic Control Systems: Many machines use programmable controllers (e.g., Siemens HMI) for precise adjustment of speeds, feed rates, and head positioning, allowing for fine-tuned deburring.

3. Specialized Deburring Processes

Deslagging: Heavy-duty deslagging units are available in some machines, particularly for metal processed by plasma or flame cutting, which leaves substantial slag on the surface.

Edge Rounding: These machines can handle both standard and fine edge rounding, achieving smooth R angles on edges and holes, which is important for safety and quality.

Oxide Removal: Machines equipped with oxide removal heads can eliminate oxide layers, especially for stainless steel and aluminum, to improve weldability and surface quality.

4. Popular Models and Series

LSP Series: Known for a combination of abrasive belt and barrel brush, the LSP series provides both deburring and finishing in one pass with low user costs, available in multiple widths.

MHT Series CNC Precision Levelers: These machines provide high-precision leveling with integrated deburring and finishing options for thicker metals, ideal for heavy-duty applications.

RRP5340 Machine: A versatile deburring and polishing system with multiple belt and brush options, suitable for narrower workpieces.

Main technical parameters:

| Parameter | Specification |

| Processing Width | ≤800mm |

| Processing Thickness | 0.5~80mm |

| Minimum Processing Size | 50mm×50mm (Carbon steel) |

| Total Power | 20.25KW |

| Steel Hammerhead Brush Size | Φ162mm |

| Sanding Belt Size | Φ3530mm×80mm (60# Zirconium Corundum) |

| Rotary Brush Size | Φ300mm×300mm (120# from Germany’s Kisterbo) |

| Conveyor Feed Speed | 0.5~6m/min (frequency adjustable) |

| Sanding Belt Line Speed | 12m/s |

| Brush Rotation Speed | 8~26m/s (frequency adjustable) |

| Planetary Brush Revolution Speed | 1~15r/min (frequency adjustable) |

| Number of Planetary Brush Revolution Shafts | 1 |

| Number of Planetary Brush Rotation Shafts | 4 |

| Servo Precision for Thickness Adjustment | 0.01mm |

| Servo Precision for Brush Compensation | 0.01mm |

| Abrasives Used | sanding belt + rotary brush |

| Worktable Load Capacity | ≤400kg |

| Dust Extraction Air Volume | 5000m³/h |

| Machine Dimensions (L×W×H) | 4100mm×1900mm×2200mm |

| Machine Weight | Approx. 3 tons |

Advantages of the Machine:

Increased Production Efficiency: Continuous feed-through processing meets high production demands.

Improved Product Quality: Consistent surface treatment, exceeding manual results.

Cost Savings: Lower processing costs per unit area compared to manual handling.

Safety and Environmental Protection: Effective dust extraction improves worker safety and the working environment.

Specifications:

Key Components and Functions

Drum Unit:

The drum unit is used for heavy-duty grinding, ensuring efficient removal of slag, burrs, and other imperfections caused by processes like laser cutting, plasma cutting, or flame cutting.

It provides aggressive material removal, preparing the workpiece for more delicate finishing processes.

Rotary Brush Unit:

The rotary brush provides excellent edge rounding and deburring. It rotates to ensure that edges and internal holes are smooth and evenly processed, creating consistent results.

Effective for creating an edge radius up to 2.0 mm, ensuring all sharp corners are smooth and safe for handling.

Hammerhead Rotary Brush:

The Hammerhead Rotary Brush offers a more intense brushing action, capable of handling tougher tasks like laser oxide removal and heavy slag removal.

This unique brush configuration allows for deep cleaning and polishing, especially for parts with challenging geometries or coatings.

Applications

Deburring: Removes burrs from various cutting processes such as laser cutting, stamping, and plasma cutting, ensuring a clean and smooth part surface.

Edge Radiusing: Smooths sharp edges and produces a consistent radius on part edges, preventing injury and improving safety.

Finishing: Achieves a superior surface finish, ready for further coating or painting processes.

Laser Oxide Removal: Effectively removes oxide layers that form on metal surfaces during laser cutting, improving adhesion for paint and coatings.

Heavy Slag Removal: Ideal for thicker materials where heavy slag forms, the drum and hammerhead rotary brush efficiently remove excess material without damaging the base part.

Machine Benefits

Versatile Processing: Capable of handling a wide range of metals, including stainless steel, carbon steel, aluminum, and other non-ferrous metals.

Multiple Functions: Combines grinding, deburring, and finishing into one machine, reducing the need for multiple processing steps.

Efficiency: The dry processing system allows for high-speed material removal and finishing, while reducing downtime and consumable costs.

Adjustable: Variable speed controls and adjustable pressure settings allow operators to fine-tune the process for specific material needs.

Consistent Results: Ensures uniform deburring, edge rounding, and finishing across large batches of parts, maintaining high quality and consistency.