Sheet Metal Forming Machine

Universal Forming Machine for Cold Forming of Sheet Metal and Profiles

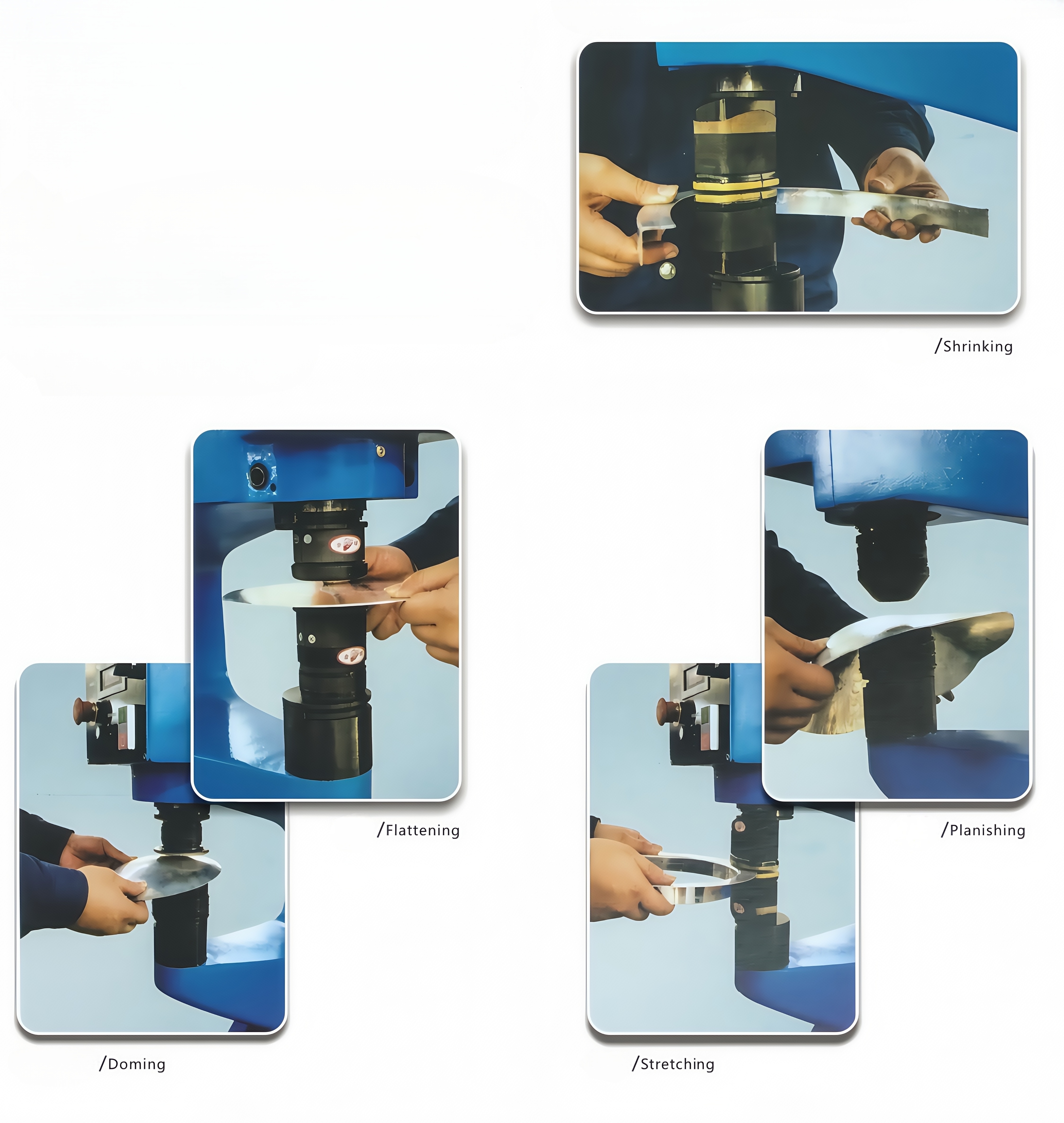

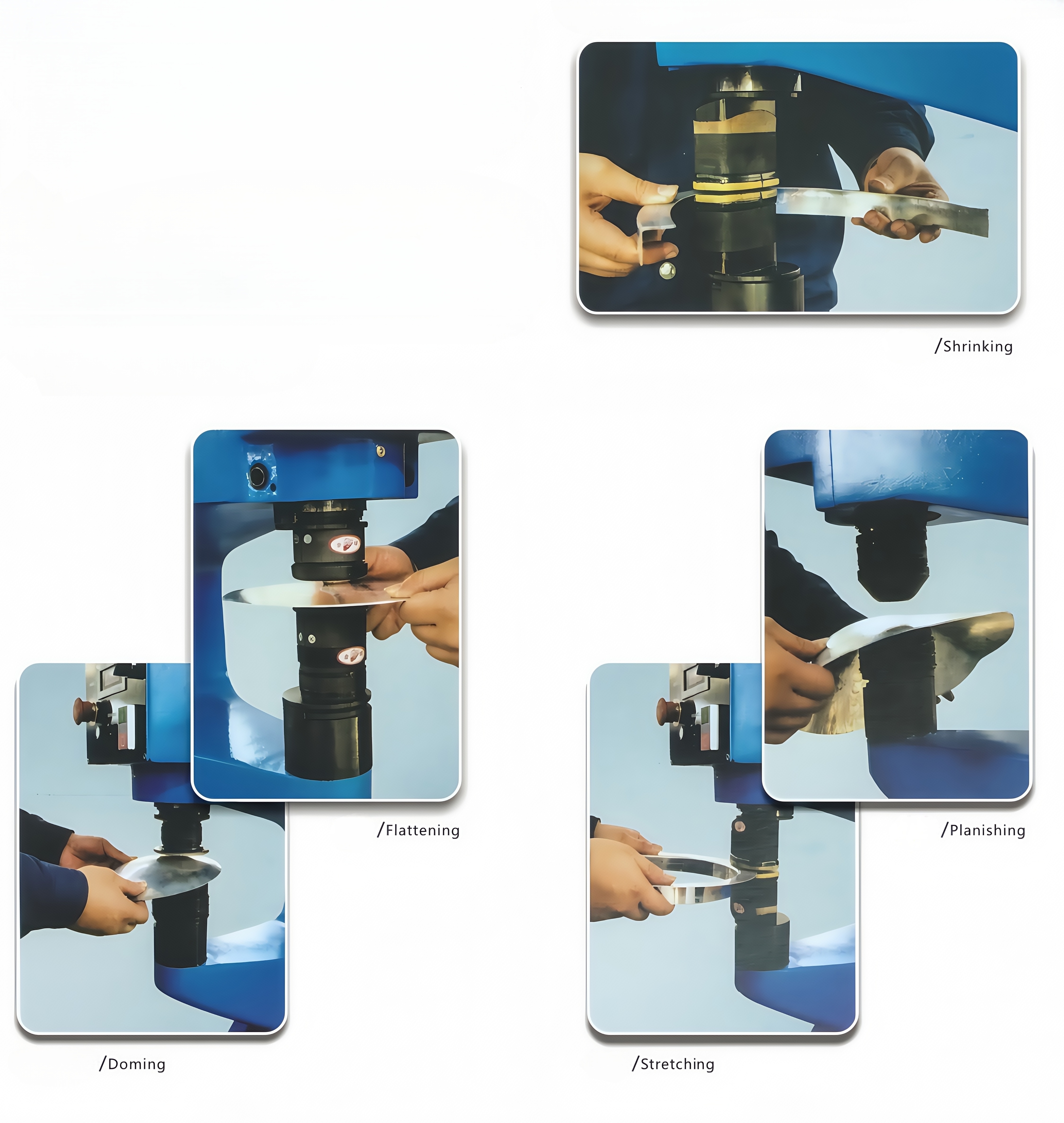

This universal forming machine is specifically designed for cold forming operations on sheet metal and profiles. It performs a wide range of processes including stretching, shrinking, curving, flattening, doming, planishing, straightening, and reforming. Motor-driven and equipped with a steplessly adjustable lifting speed, it ensures precise and efficient forming across different materials and thicknesses.

The CX08×350 is an advanced sheet metal forming machine and the most powerful model in the KF series. The series includes two different configurations, but our focus is on this largest model. In addition to its size, this machine features an eye-level control panel with an easy-to-read LCD display, indicating its multifunctional capabilities and powerful programmability.

What is the CX08×350?

It is a high-precision, controlled sheet metal forming system, a cutting-edge piece of technology designed to shape flat metal panels into various complex forms. Whether it’s a workshop restoring vintage vehicles or a machine shop crafting beautifully detailed metal components, they all share the same need: a large-scale metalworking tool like this. Without it, those classic cars would be stuck with flat, unshaped panels, and shops would be limited to two-dimensional metal sheets.

Going Beyond Two-Dimensional Fabrication

To expand on that, the CX08×350 adds contours and three-dimensional depth to sheet metal parts. While cutting and shearing tools can produce good-looking components, the results are inherently flat. The CX08×350, on the other hand, bends and forms material into shape. With a horizontal throat depth of 160–198 mm, it can handle larger workpieces and allows them to be rotated without creating wrinkles or creases. Most importantly, this is a multifunctional machine. There’s no need to switch between planishing and doming tools—this unit integrates planishing, doming, flattening, shrinking, and stretching into one machine.

Versatility in Material Processing

To enhance its utility, this sheet metal forming machine has been carefully engineered to accommodate a variety of materials. Its extended throat depth and forming tools can process material as thick as 7-gauge steel (approximately 4.5 mm). Controlled by 25 preset programs, it offers a semi-automated workflow while maintaining full manual control for the operator. All programming functions are clearly displayed on a large, easy-to-read LCD screen, ensuring user-friendly operation.

Though compact in structure, this C-frame machine is large enough to handle demanding jobs. It stands about as tall as the average person, positioning the display at eye level for comfortable use. A foot pedal is also included, allowing the operator to adjust stroke speed on the fly without letting go of the workpiece. With a stroke rate ranging from 150 to 400 strokes per minute, the CX08×350 can easily take on tasks that would otherwise require multiple single-function machines.

Technical Parameters

| Item | CX08×350 |

| Open Height (Distance between upper and lower tool connection surfaces) | 160–198 mm |

| Vibration Range (Up and down stroke) | 8 mm |

| Adjustable Range (Feeding stroke) | 30 mm |

| Vibration Frequency | 400 strokes/min |

| Adjustable Angle of Machine Body | 15° |

| Max. Formable Thickness |

|

| — Steel (σ<sub>s</sub> = 450 MPa) | ≤ 2.0 mm |

| — Aluminum (σ<sub>s</sub> = 250 MPa) | ≤ 2.5 mm |

| — Copper (σ<sub>s</sub> = 250 MPa) | ≤ 2.0 mm |

| — Stainless Steel (σ<sub>s</sub> = 450 MPa) | ≤ 1.5 mm |

| Weight | 500 kg |

| Dimensions (L×W×H) | 1720 × 1040 × 1666 mm |