Precision Laser Cutting Services for Stainless Steel SMT Stencils

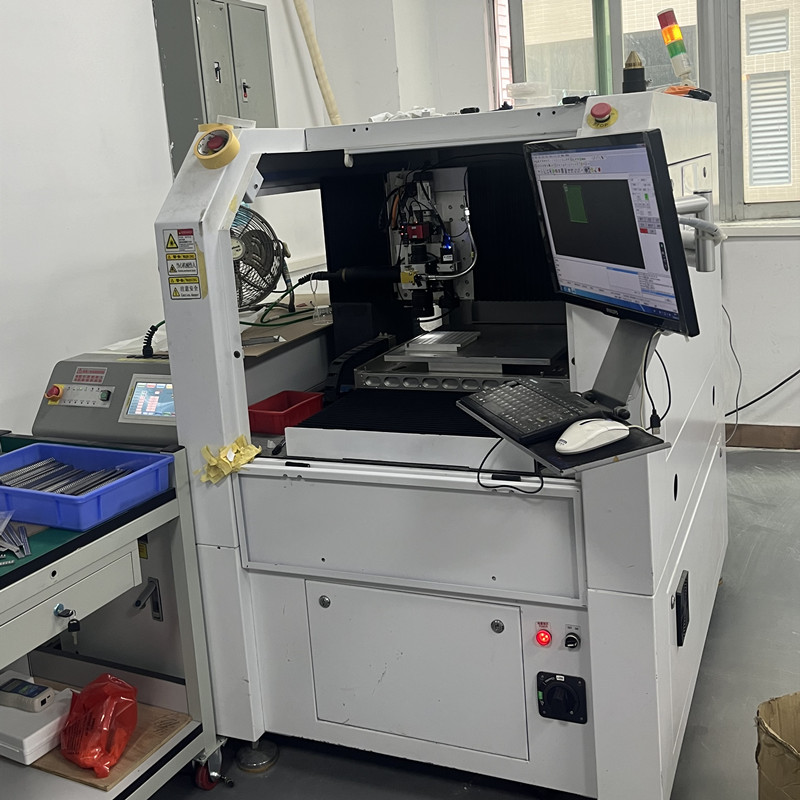

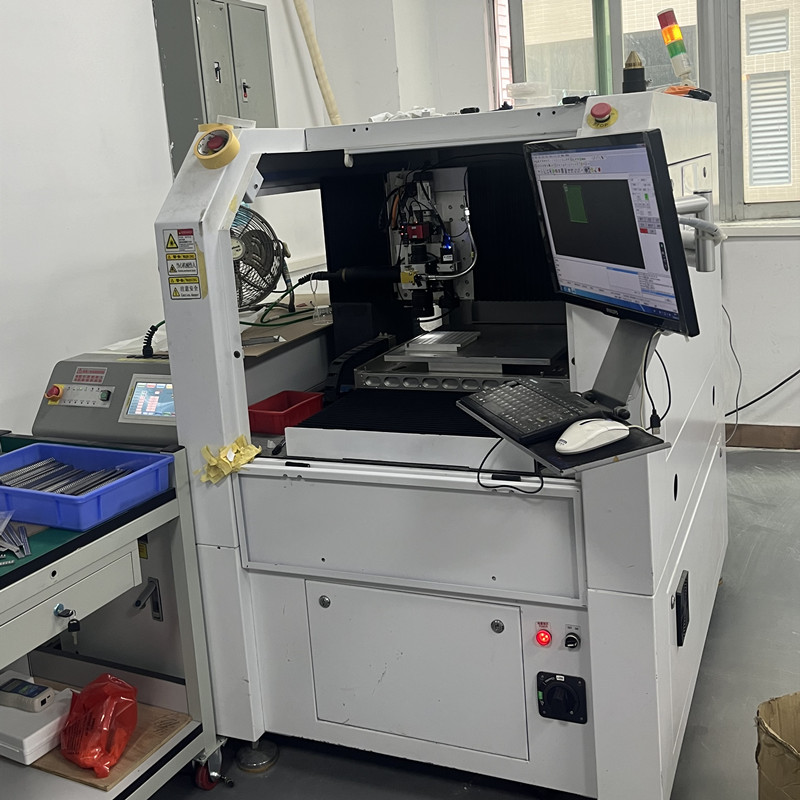

Technology Used: 100% Laser Cut (using advanced laser cutting services)

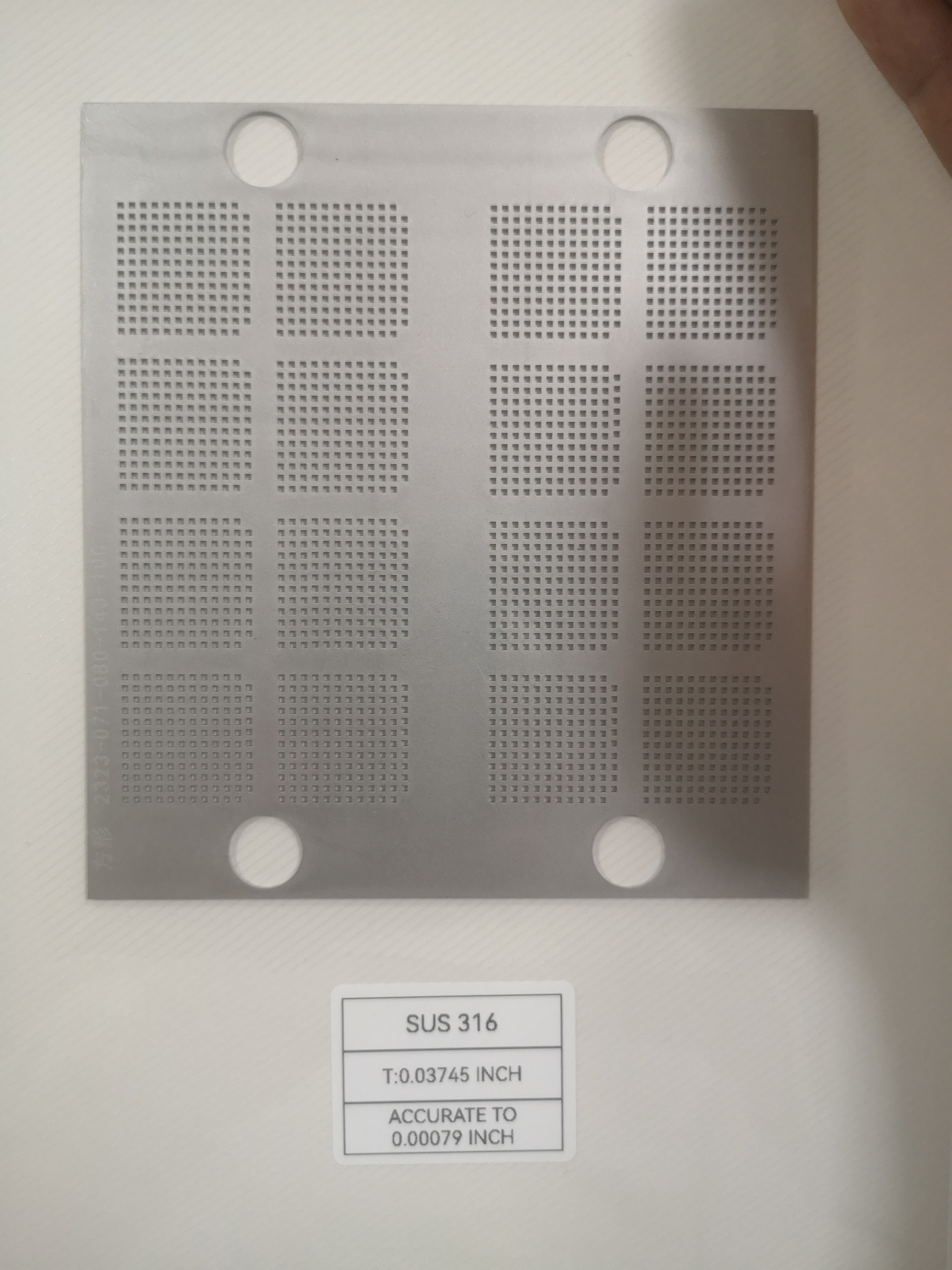

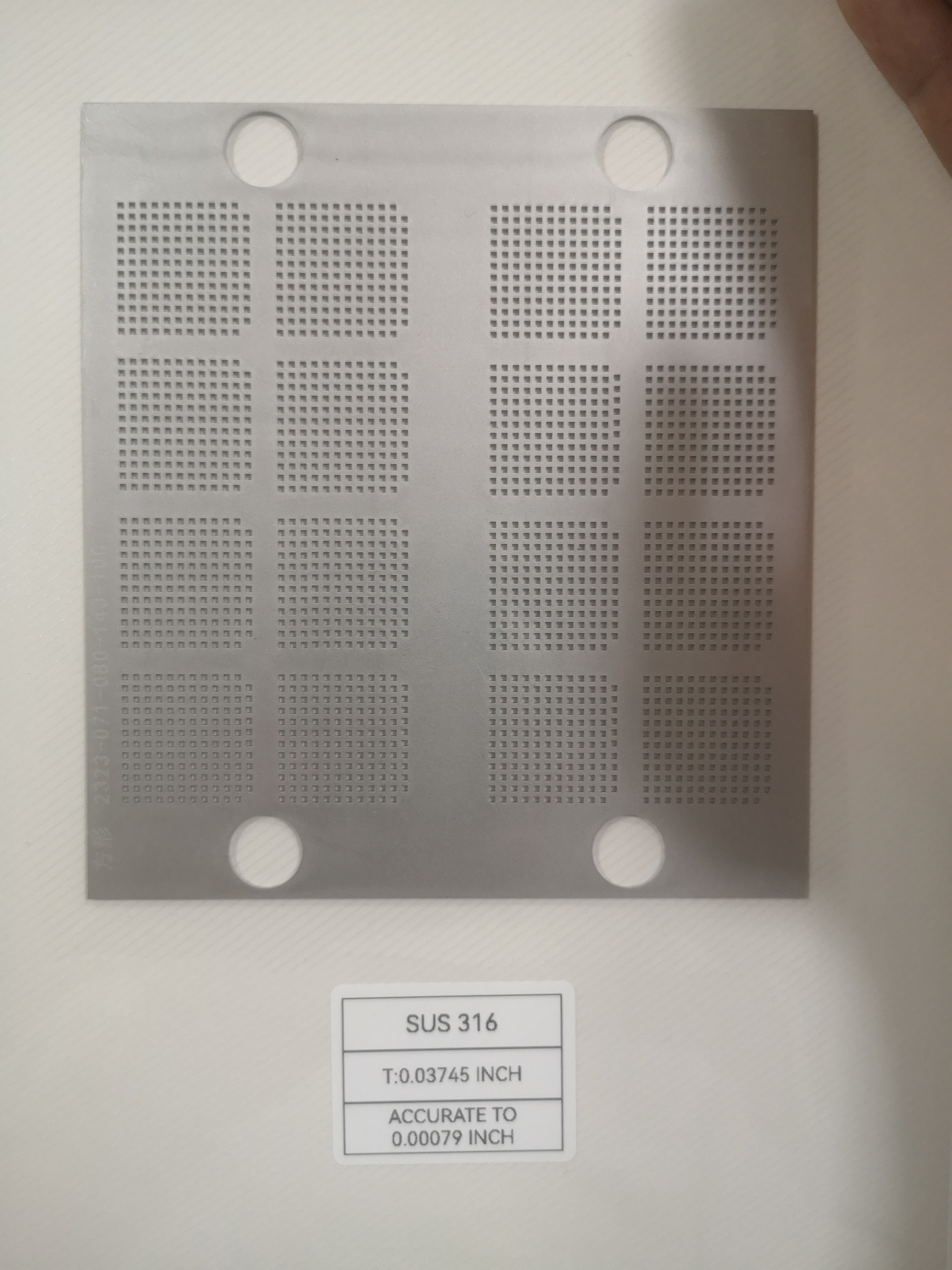

Material: High-quality Stainless Steel

Stencil Thickness: Available in 0.004 inches and 0.005 inches

Minimum Cut Width: As fine as 0.0025 inches

Maximum Size: Up to 10" x 10"

Aperture Tolerance: Within 0.00025 inches for high precision

Function and Application of Precision Laser Cutting Stainless Steel SMT Stencils

Laser cutting technology is widely used in Surface Mount Technology (SMT), particularly in the manufacturing of high-precision SMT stencils. Below is an introduction to the functions and applications of precision laser cutting stainless steel SMT stencils:

Key Features

High Precision Cutting:

Laser cutting provides aperture tolerances of up to 0.00025 inches, ensuring precise hole positions and cutting edges for accurate solder paste printing on PCBs.

Burr-Free and Stress-Free Finishing:

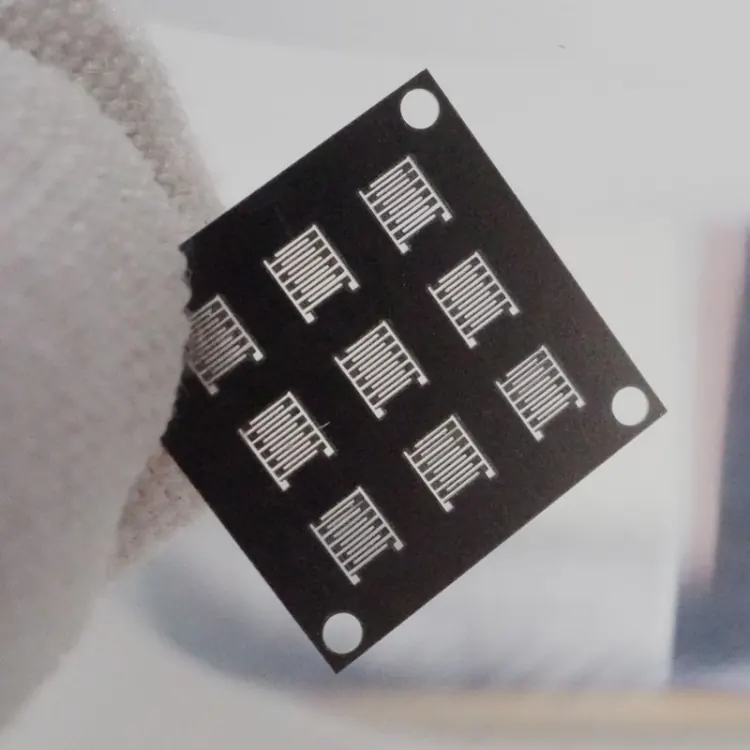

The laser cutting process ensures smooth, burr-free edges and stress-free cutting, enhancing the stencil's durability and stability.

Various Thickness Options:

Available in 0.004 inches and 0.005 inches thicknesses, these stencils meet the soldering needs of different PCB types.

Minimum Cut Width:

Laser cutting can achieve a minimum cut width of 0.0025 inches, suitable for small, precise pad designs, ideal for micro-components and high-density circuit boards.

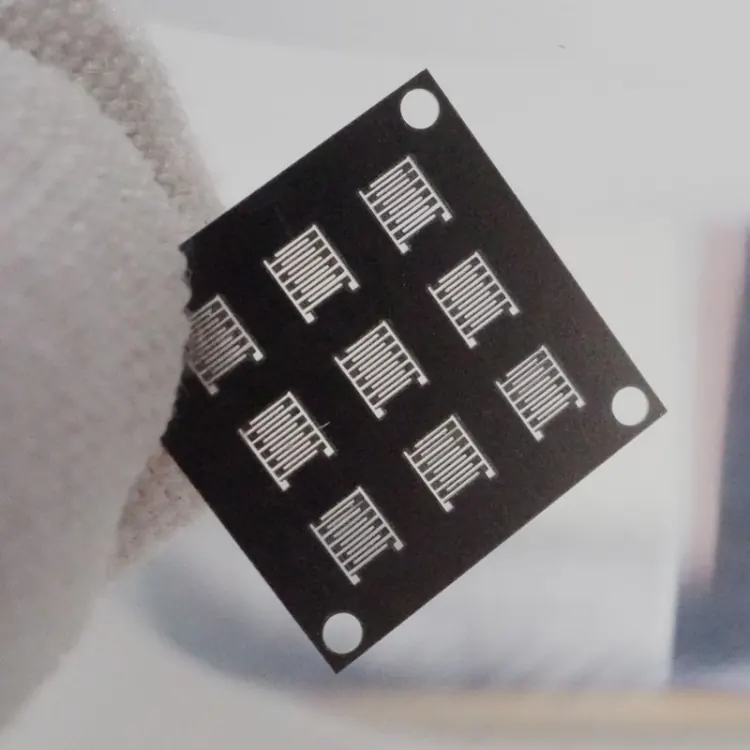

Custom Design:

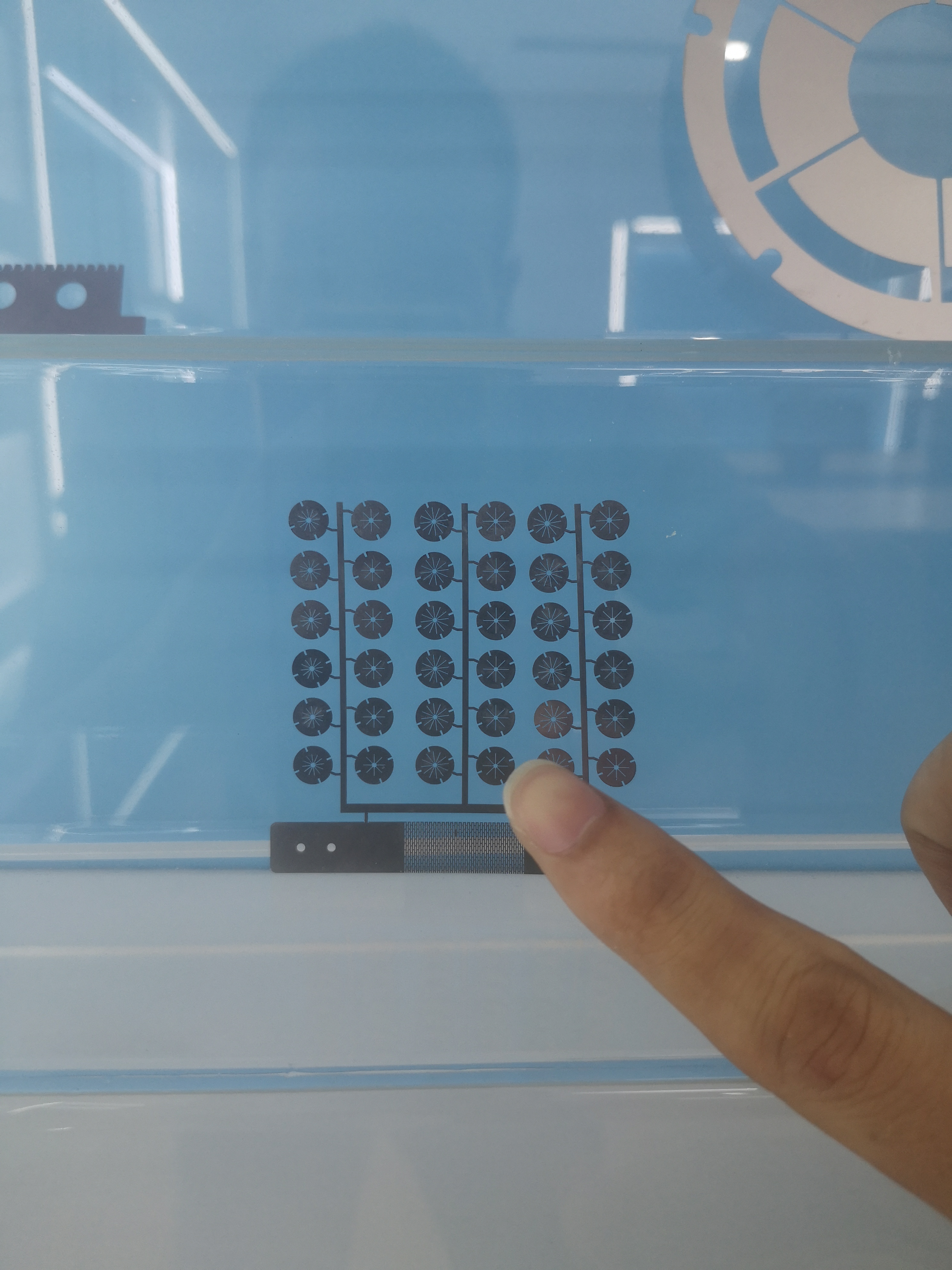

Stencils can be custom-made according to the customer's Gerber files or CAD designs, ensuring that every PCB's soldering requirements are fully met.

Applications

Prototype PCB Manufacturing:

Laser-cut SMT stencils are ideal for prototype PCB soldering, allowing for fast and precise stencil production in prototype design and small batch production, saving time and cost.

Double-Sided SMT Assembly:

Laser-cut stencils support double-sided SMT assembly. Whether for single-sided or double-sided assembly, these stencils ensure accurate solder paste printing for high-quality solder joints.

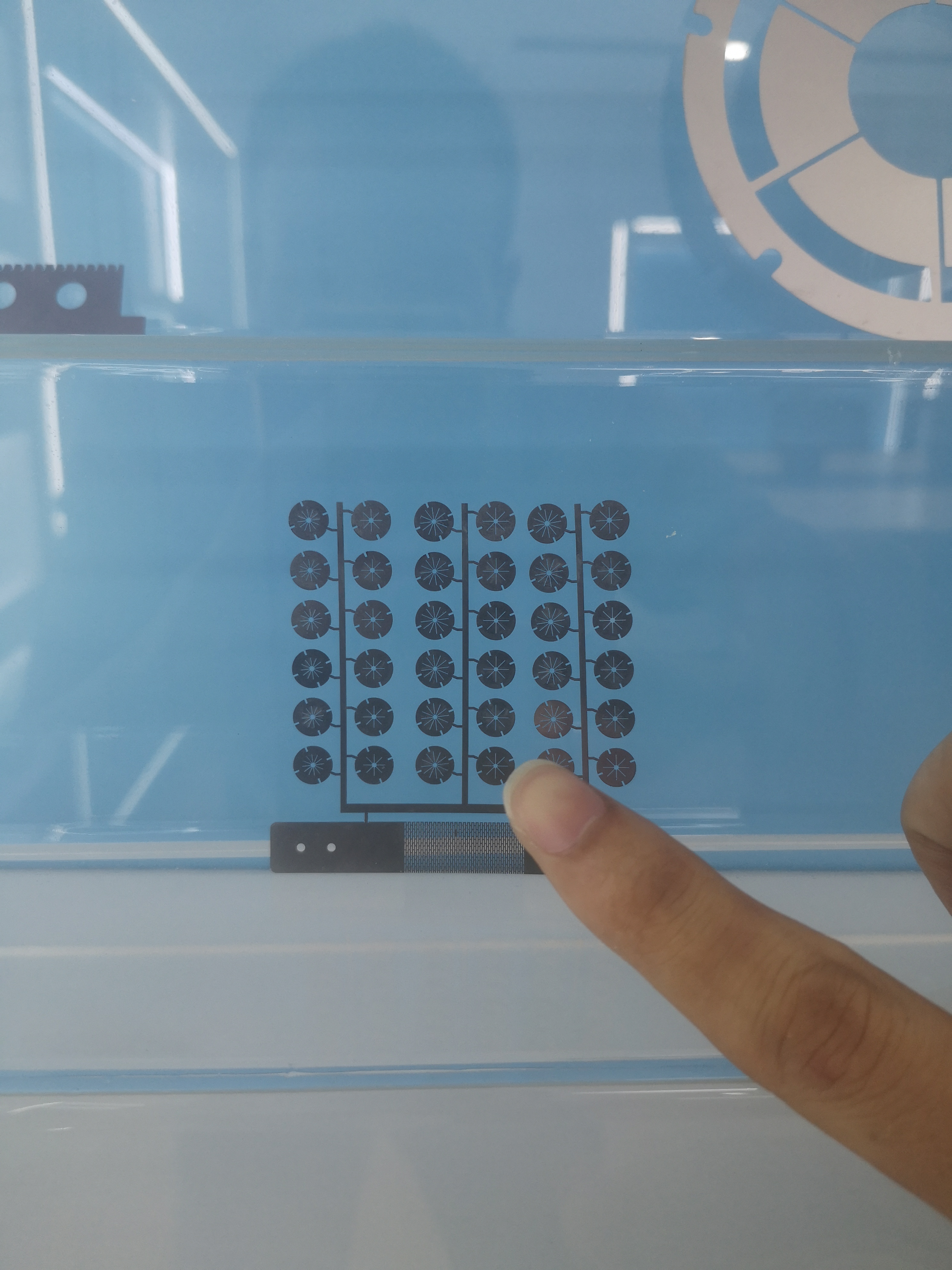

High-Density and Micro-Component Assembly:

Laser cutting supports precise cutting and features for small pads and high-density soldering applications, ensuring accurate soldering of micro-components and BGA (Ball Grid Array) packages.

Precise Solder Paste Printing:

Laser-cut SMT stencils guarantee accurate solder paste printing, reducing the risk of solder defects and improving the overall quality of PCB assemblies.

High-Frequency and High-Power Applications:

In RF (Radio Frequency) and high-power applications, precise soldering is crucial. Laser-cut stencils meet the soldering demands of these high-precision applications, ensuring component stability and performance.

Automated Production Lines:

For large-scale automated production on SMT assembly lines, laser-cut stencils can be produced quickly and seamlessly integrated with automation equipment (such as pick-and-place machines), improving production efficiency.

Quality Control and Verification:

Each laser-cut stencil undergoes strict quality control to ensure that each hole and pad pattern meets the required standards. Users can also opt to include fiducial marks for further registration accuracy.

Conclusion

Precision laser cutting stainless steel SMT stencils, with their high precision, fast turnaround, and customizable design, are widely used in PCB assembly, prototype development, and high-precision electronic device manufacturing. Their superior processing accuracy and customizability make them an ideal solution for both small batch production and high-density component soldering needs, playing a vital role in modern electronics manufacturing.