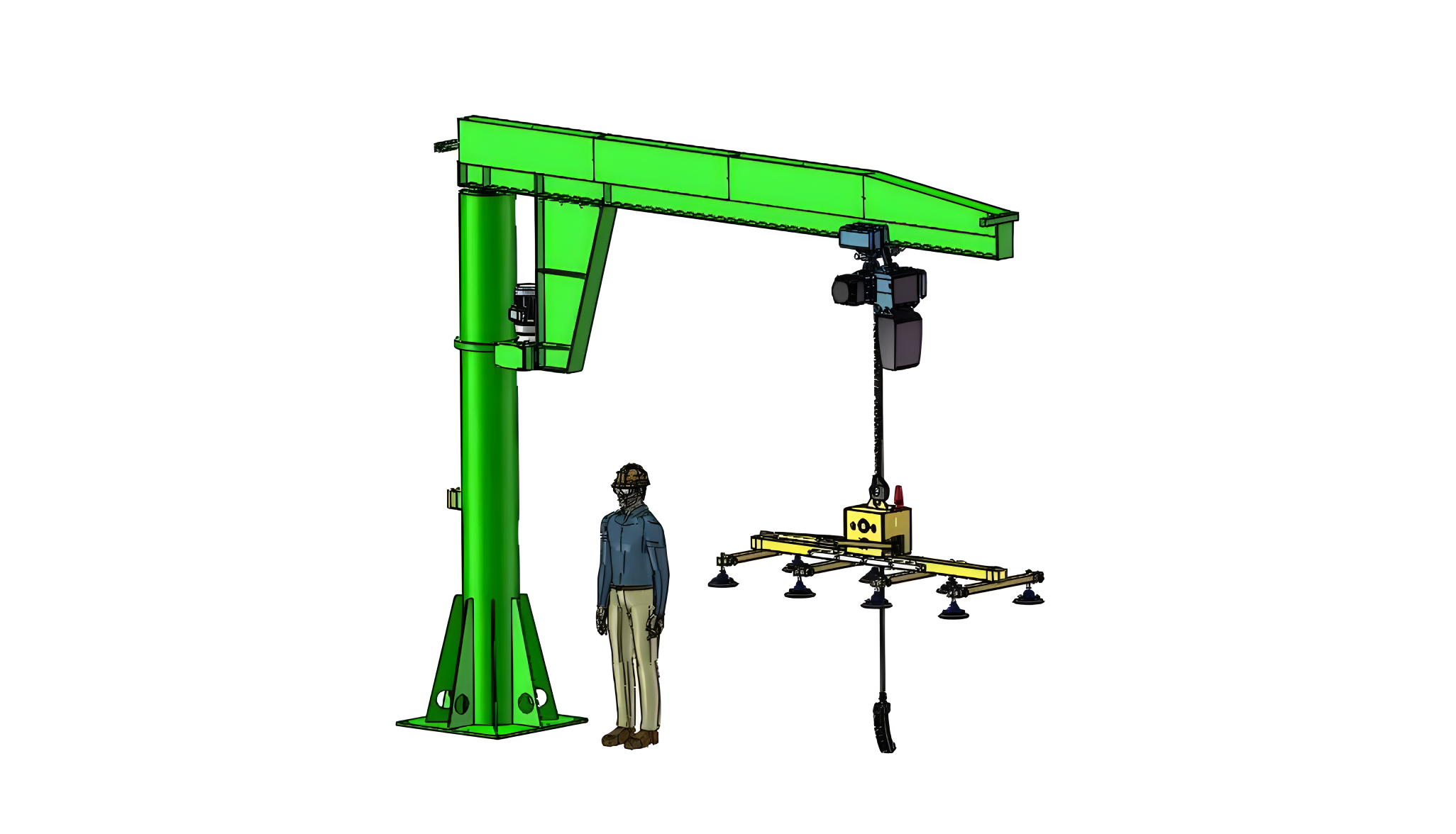

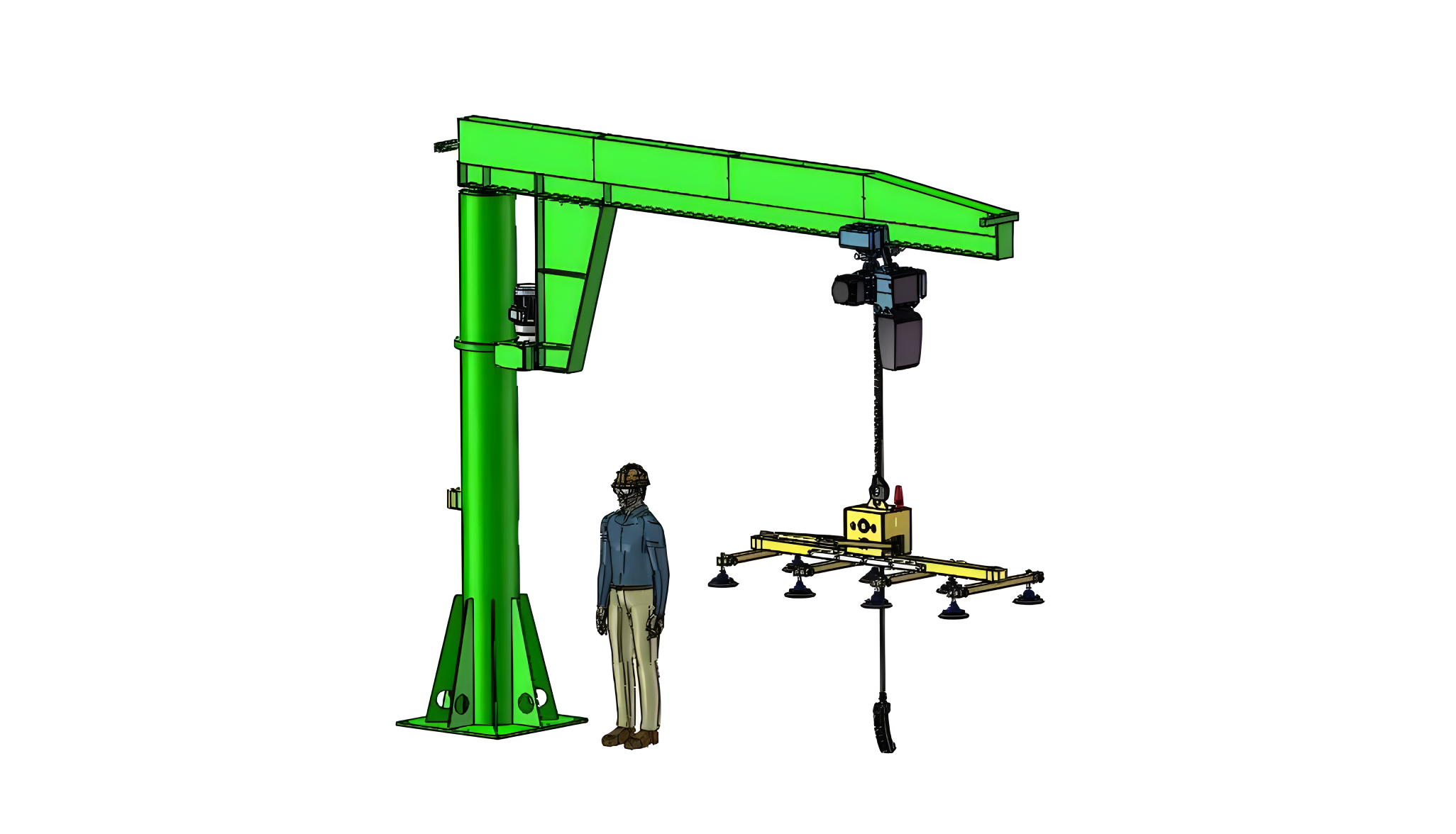

A vacuum lifter for sheet metal is a lifting device specifically designed for handling, lifting, and transporting metal sheets using vacuum suction. These lifters use suction cups to grip the surface of the metal sheet securely without causing damage, making them ideal for handling flat and smooth materials such as steel, aluminum, and stainless steel sheets.

Key Features of Vacuum Lifters for Sheet Metal:

Suction Technology:

The lifter employs vacuum suction cups that attach to the metal sheet's surface, allowing for easy, secure lifting and transport. It can handle various sheet materials like steel, aluminum, and stainless steel.

Material Compatibility:

Suitable for iron sheets, aluminum sheets, stainless steel sheets, and non-metallic smooth sheets like plastic. Magnetic vacuum cups are used for ferrous materials, while traditional vacuum cups handle non-ferrous metals and other materials.

Rated Load Capacity:

Suction Cup Configuration:

Automation Options:

Operation Types:

Pneumatic Vacuum Lifters: These require a compressed air source to create the vacuum suction. They are used in industries where compressed air is readily available.

Battery-Powered Vacuum Lifters: Portable and convenient for locations without a permanent power supply, they operate using rechargeable batteries.

Electric Plug-In Vacuum Lifters: These use electricity (AC 220V/380V) to power the vacuum pump and are suitable for long-term operations where continuous power is needed.

Applications:

Sheet Metal Processing:

Ideal for loading and unloading metal sheets during laser cutting, stamping, bending, or CNC processing operations.

Metal Fabrication:

Construction:

Manufacturing:

Advantages:

Damage-Free Handling:

Increased Efficiency:

They speed up the loading, unloading, and transport processes, especially when integrated into automated systems.

Enhanced Safety:

Flexibility:

Versatility:

Typical Specifications:

Rated Load: 300-800 kg

Suction Cup Diameter: 150mm – 200mm

Number of Suction Cups: 6-8 suction cups

Power Source: Pneumatic, battery-powered, or plug-in electric

Sheet Size Range: From small (2000×1000mm) to large sheets (4000×2000mm)

Pneumatic Vacuum Lifter

| Product Model | JS-300-2M/3M |

| Rated Load (kg) | 300 |

| Suction Cup Diameter (mm) | 150 |

| Number of Suction Cups | 8 |

| Outer Dimensions (mm) | 2000×1000, 3000×1000, 3000×1500, 4000×2000 |

| Plate Dimensions (mm) | 3000×1500, 4000×2000 |

| Working Voltage | 0.8 MPa Air Supply |

Battery-Powered Vacuum Lifter

| Product Model | JS-JG300-2M/3M | JS-JG600-2M/3M | JS-JG800-2M/3M |

| Rated Load (kg) | 300 | 600 | 800 |

| Suction Cup Diameter (mm) | 150 | 150 | 150 |

| Number of Suction Cups | 8 | 6 | 6 |

| Outer Dimensions (mm) | 2000×1000, 3000×1000, 3000×1500, 4000×2000 | Same as JS-JG300-2M/3M | Same as JS-JG300-2M/3M |

| Plate Dimensions (mm) | 3000×1500, 4000×2000 | Same as JS-JG300-2M/3M | Same as JS-JG300-2M/3M |

| Working Voltage | DC12V | DC12V | DC12V |

Plug-In Vacuum Lifter

| Product Model | JS-GC300-2M/3M | JS-GC600-2M/3M | JS-GC800-2M/3M |

| Rated Load (kg) | 300 | 600 | 800 |

| Suction Cup Diameter (mm) | 150 | 200 | 200 |

| Number of Suction Cups | 8 | 8 | 8 |

| Outer Dimensions (mm) | 2000×1000, 3000×1000, 3000×1500, 4000×2000 | Same as JS-GC300-2M/3M | Same as JS-GC300-2M/3M |

| Plate Dimensions (mm) | 3000×1500, 4000×2000 | Same as JS-GC300-2M/3M | Same as JS-GC300-2M/3M |

| Working Voltage | AC220V/380V | AC220V/380V | AC220V/380V |