Laser Cutting Loading and Unloading systems For sheet metal processing, especially in the laser cutting loading and unloading process, automated equipment has become essential for improving production efficiency and reducing labor costs. Automated systems designed for handling and stacking flat and smooth-surfaced materials like iron sheets, aluminum sheets, stainless steel sheets, and plastic sheets offer the following features and applications:

Main Application Scenarios:

Laser Cutting Loading and Unloading:

Automatic Loading Machine: Used to transport sheets from storage to the laser cutting machine's worktable, with automatic positioning, reducing the need for manual intervention.

Automatic Unloading Machine: After laser cutting, the machine transports the finished parts to designated areas, such as a storage system or downstream processing stations.

Stacking Operations:

Automated stacking robots can precisely stack sheets of various types and sizes, ensuring neat piling of materials, making them easier to transport or process later.

Suitable for materials like iron sheets, aluminum sheets, stainless steel sheets, plastic sheets, and other smooth-surfaced products, minimizing the risk of scratches or deformation.

Equipment Features:

Applicable Materials:

Metal Sheets: Including iron sheets, aluminum sheets, stainless steel sheets, and other metal materials with a wide range of thicknesses.

Non-Metal Sheets: Suitable for flat and smooth materials such as plastic sheets.

Automation Control:

CNC System: The equipment is equipped with an advanced CNC system, which precisely controls the transport, positioning, and stacking of sheets, enabling efficient production.

Multi-Axis Robotic Arm: Typically equipped with a multi-axis robotic arm capable of handling sheets of various sizes and specifications, ensuring that the sheets are not deformed or scratched during handling.

Safety and Efficiency:

Automated handling equipment reduces risks associated with manual operations, such as the heavy weight of sheets or sharp edges that can cause injury to workers.

Significantly improves production efficiency, particularly in factories with batch processing, where automated handling systems ensure continuous production.

Suction System:

Usually equipped with a vacuum suction system or electromagnetic suction cups suitable for handling smooth-surfaced sheets.

Vacuum suction is suitable for materials like aluminum sheets, stainless steel sheets, and plastic sheets, while electromagnetic suction cups are mainly used for iron sheets or other magnetic materials.

Flexible Processing:

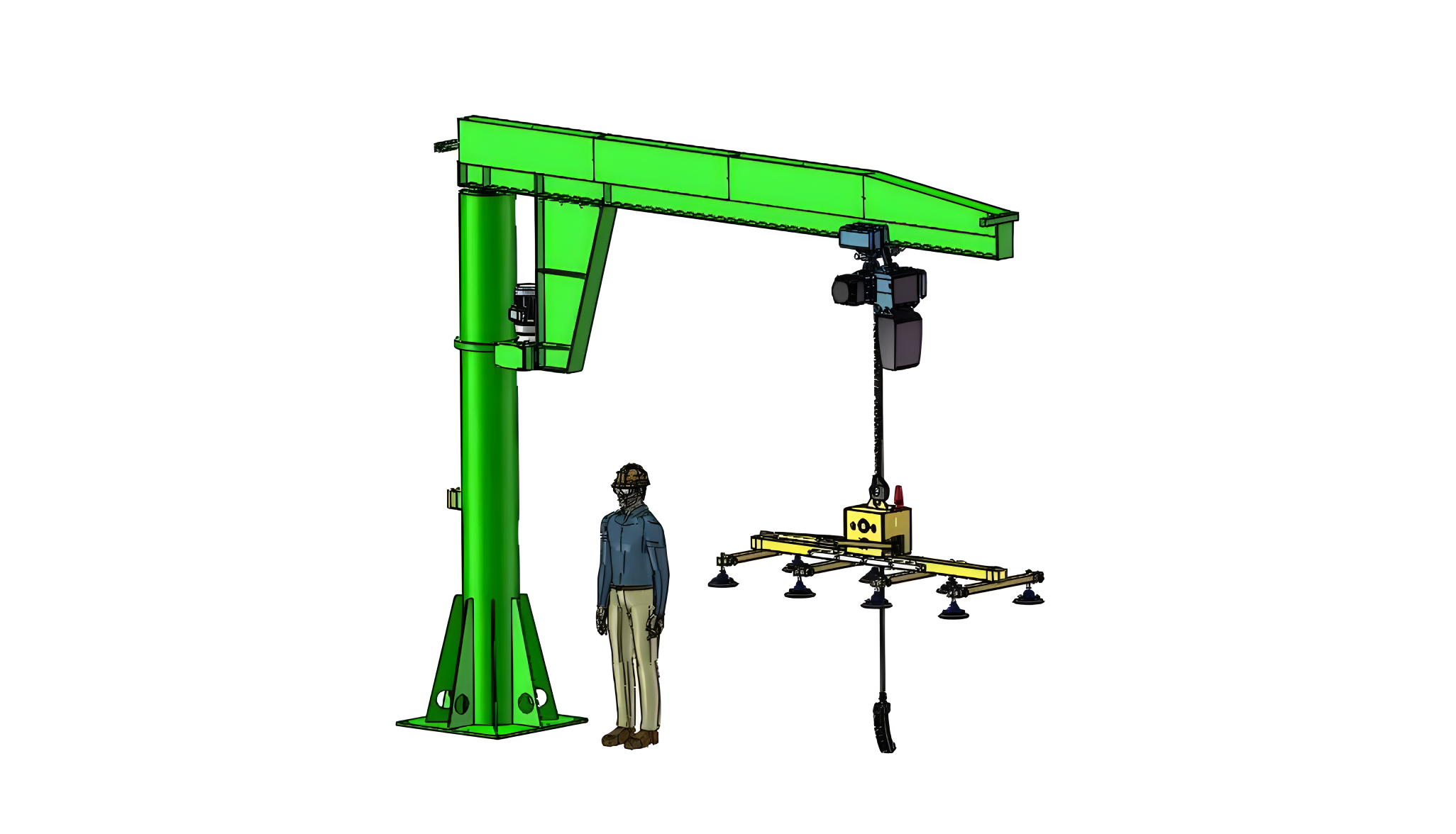

Pneumatic Vacuum Lifter

| Product Model | JS-300-2M/3M |

| Rated Load (kg) | 300 |

| Suction Cup Diameter (mm) | 150 |

| Number of Suction Cups | 8 |

| Outer Dimensions (mm) | 2000×1000, 3000×1000, 3000×1500, 4000×2000 |

| Plate Dimensions (mm) | 3000×1500, 4000×2000 |

| Working Voltage | 0.8 MPa Air Supply |

Battery-Powered Vacuum Lifter

| Product Model | JS-JG300-2M/3M | JS-JG600-2M/3M | JS-JG800-2M/3M |

| Rated Load (kg) | 300 | 600 | 800 |

| Suction Cup Diameter (mm) | 150 | 150 | 150 |

| Number of Suction Cups | 8 | 6 | 6 |

| Outer Dimensions (mm) | 2000×1000, 3000×1000, 3000×1500, 4000×2000 | Same as JS-JG300-2M/3M | Same as JS-JG300-2M/3M |

| Plate Dimensions (mm) | 3000×1500, 4000×2000 | Same as JS-JG300-2M/3M | Same as JS-JG300-2M/3M |

| Working Voltage | DC12V | DC12V | DC12V |

Plug-In Vacuum Lifter

| Product Model | JS-GC300-2M/3M | JS-GC600-2M/3M | JS-GC800-2M/3M |

| Rated Load (kg) | 300 | 600 | 800 |

| Suction Cup Diameter (mm) | 150 | 200 | 200 |

| Number of Suction Cups | 8 | 8 | 8 |

| Outer Dimensions (mm) | 2000×1000, 3000×1000, 3000×1500, 4000×2000 | Same as JS-GC300-2M/3M | Same as JS-GC300-2M/3M |

| Plate Dimensions (mm) | 3000×1500, 4000×2000 | Same as JS-GC300-2M/3M | Same as JS-GC300-2M/3M |

| Working Voltage | AC220V/380V | AC220V/380V | AC220V/380V |

Typical Equipment Applications:

Sheet Metal Processing Industry: Primarily used for loading and unloading sheets in laser cutting, stamping, bending, and other processes.

Metal Processing Plants: Suitable for bulk handling and stacking of metal sheets, especially during long-term, high-frequency operations, where automated equipment can effectively reduce errors and waste.

Home Appliance Manufacturing: Automated handling equipment can be used for transporting materials like refrigerator, washing machine, and air conditioner shells, enhancing the level of automation in production lines.

Automotive Manufacturing: In the processing of automotive body panels, automatic stacking and handling equipment ensures the safe transport of large sheet metal parts.

These devices provide an efficient automated solution for sheet metal processing, significantly reducing labor intensity while improving production efficiency and product quality.