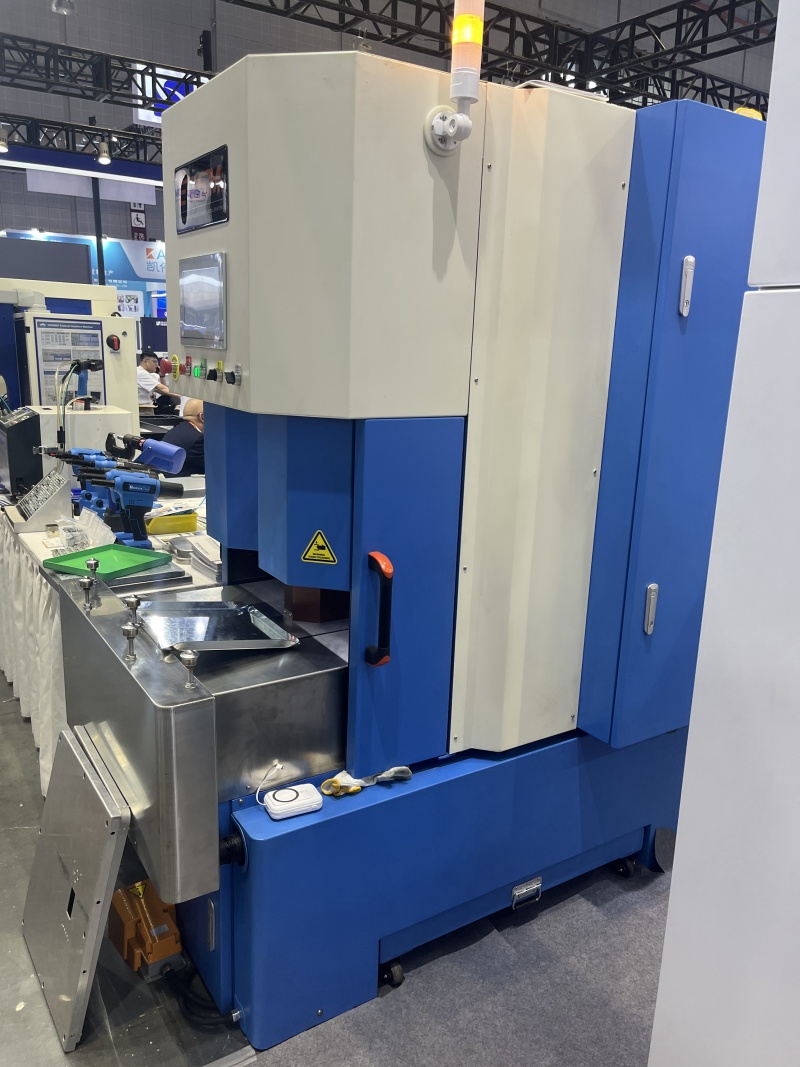

The 3050 Corner Former Machine is an advanced and flexible corner forming device specifically designed for mechanical corner forming in a wide variety of formable materials. This machine is highly efficient, requiring no welding or grinding, making it ideal for both small workshops and large-scale production environments.

Supported Materials:

Mild steel (0.5mm - 5.0mm): Including galvanized, pre-coated, and plastic-covered materials.

Aluminum (1.2mm - 5.0mm).

Stainless steel (0.5mm - 3.0mm).

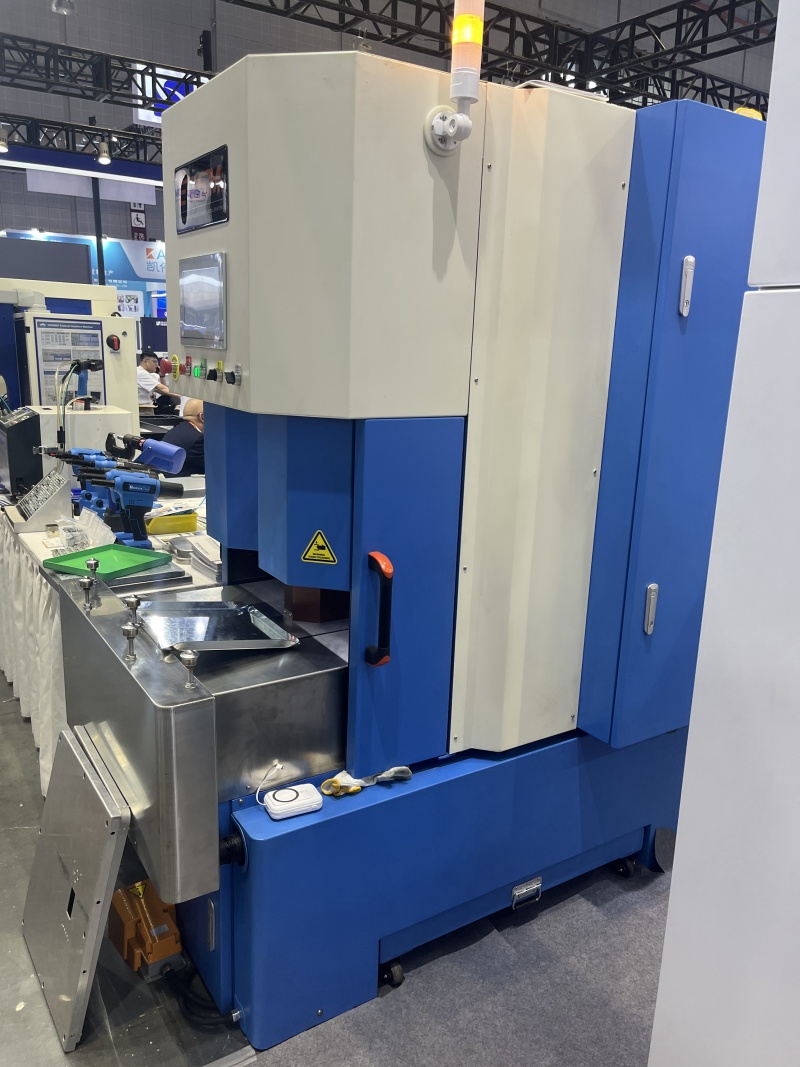

Corner Rounder Machine for Sheet Metal

Overview:The corner rounder machine is an essential tool designed to efficiently round corners on various sheet metal materials, including mild steel, stainless steel, and aluminum. This machine streamlines the fabrication process, enhancing both safety and aesthetics in metalworking projects.

Key Features:

Fast Processing: Quickly rounds corners with cycle times as low as 8 seconds, improving productivity in both small workshops and large-scale production environments.

Versatile Material Handling: Capable of processing materials up to 5 mm thick, the machine can accommodate a range of metal types and thicknesses.

Adjustable Tooling: Features adjustable tools for different flange heights and corner radii, providing flexibility for various applications.

High Precision: Achieves consistent, high-quality rounded corners with minimal material waste.

Applications:

Ideal for a variety of industries, including:

Manufacturing: Perfect for producing doors, panels, and decorative metalwork.

Road Sign Production: Effective for creating road signs in various shapes, such as quadrilaterals, triangles, and octagons.

HVAC: Used for rounding edges of ducts and components to ensure safety and compliance.

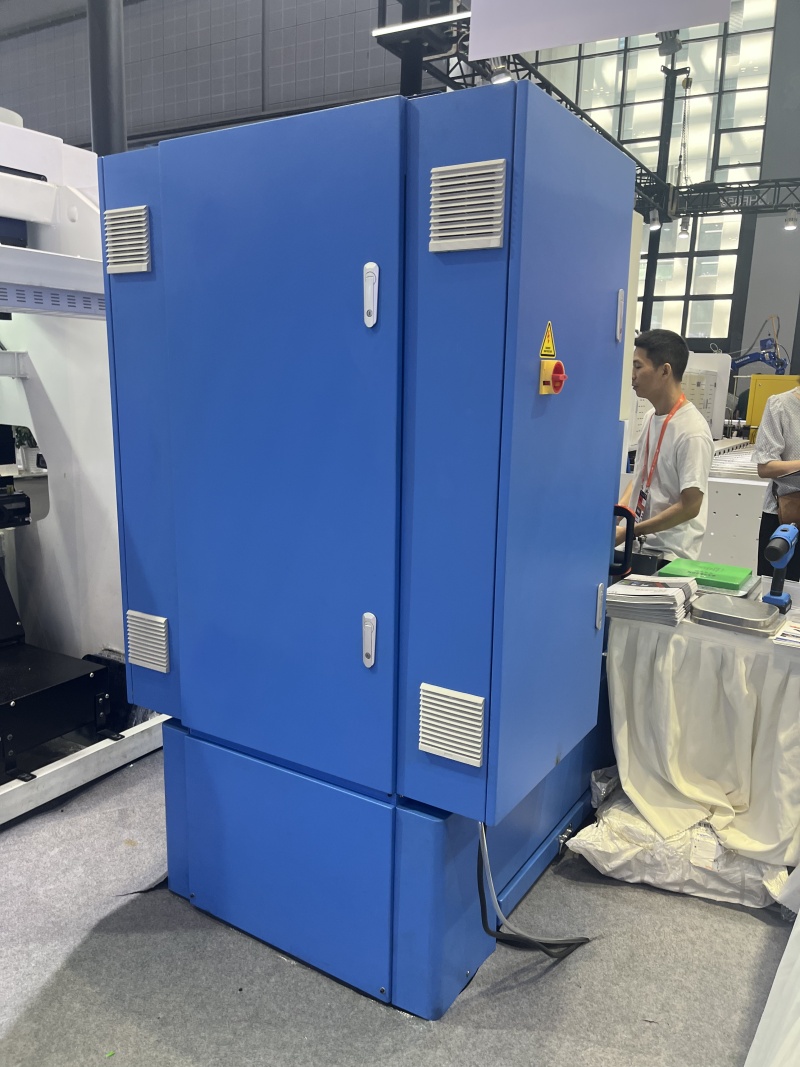

Electrical Cabinets: Rounds corners on cabinet doors for improved aesthetics and safety.

Advantages:

Cost-Effective: Reduces the need for secondary operations such as grinding or welding, lowering overall production costs.

Enhanced Safety: Eliminates sharp edges on finished parts, making them safer to handle.

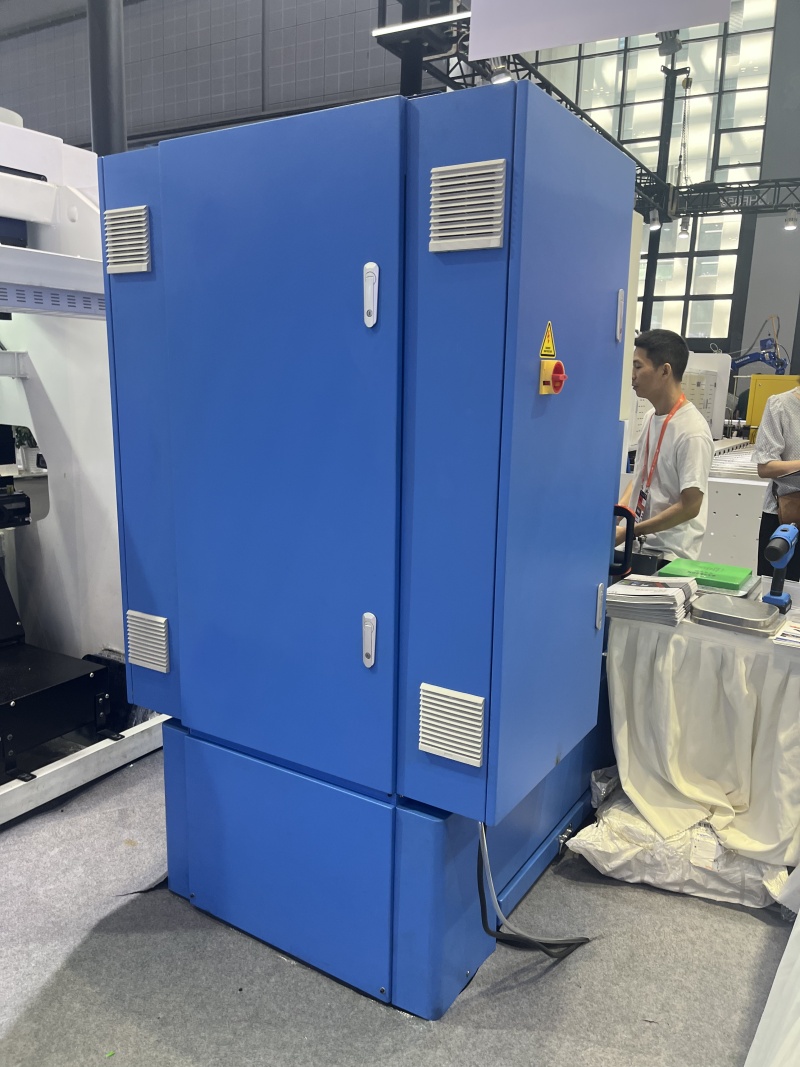

Durability: Built to withstand heavy use, ensuring long-lasting performance in demanding environments.

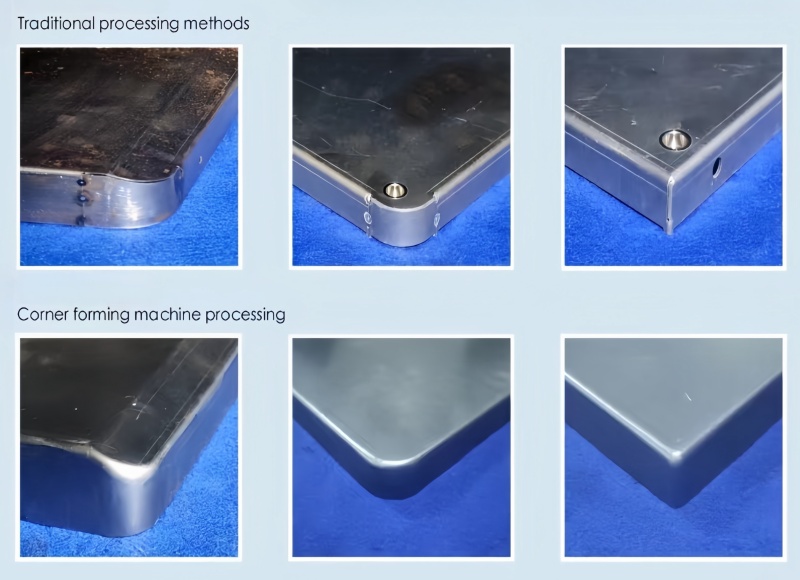

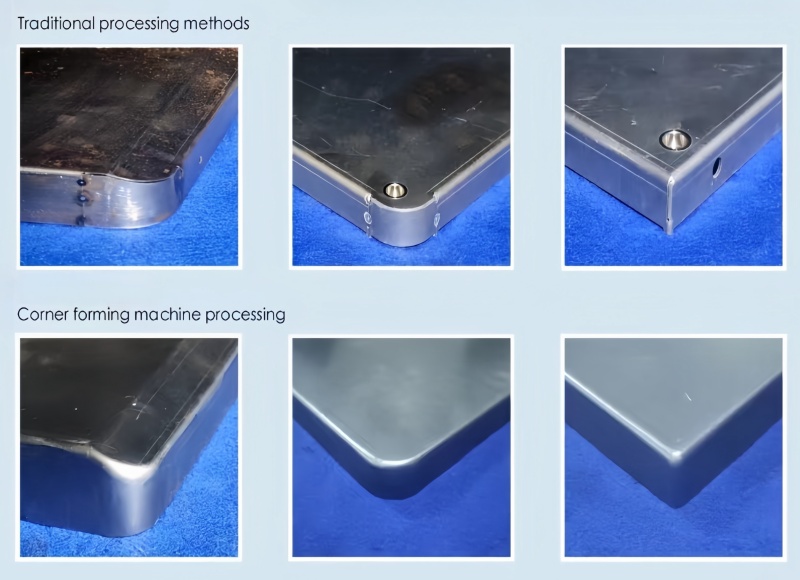

Why Choose Corner Forming?

Precision and Cost-Efficiency: Achieve perfect corners in any sheet metal at the lowest cost.

Perfect for Road Signs: Bead forming and corner rounding are done seamlessly in one step, reducing tooling costs.

Long Tool Life: Our flexible tools provide a long lifespan, making cold-forming corners more efficient than welding.