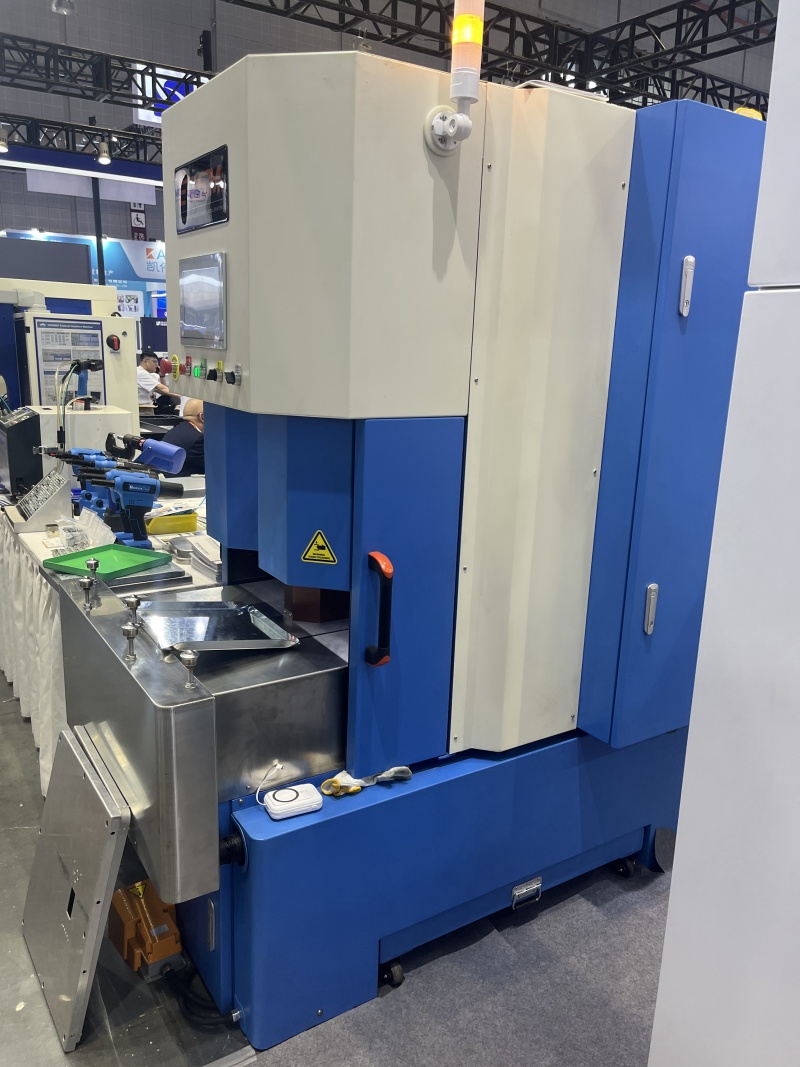

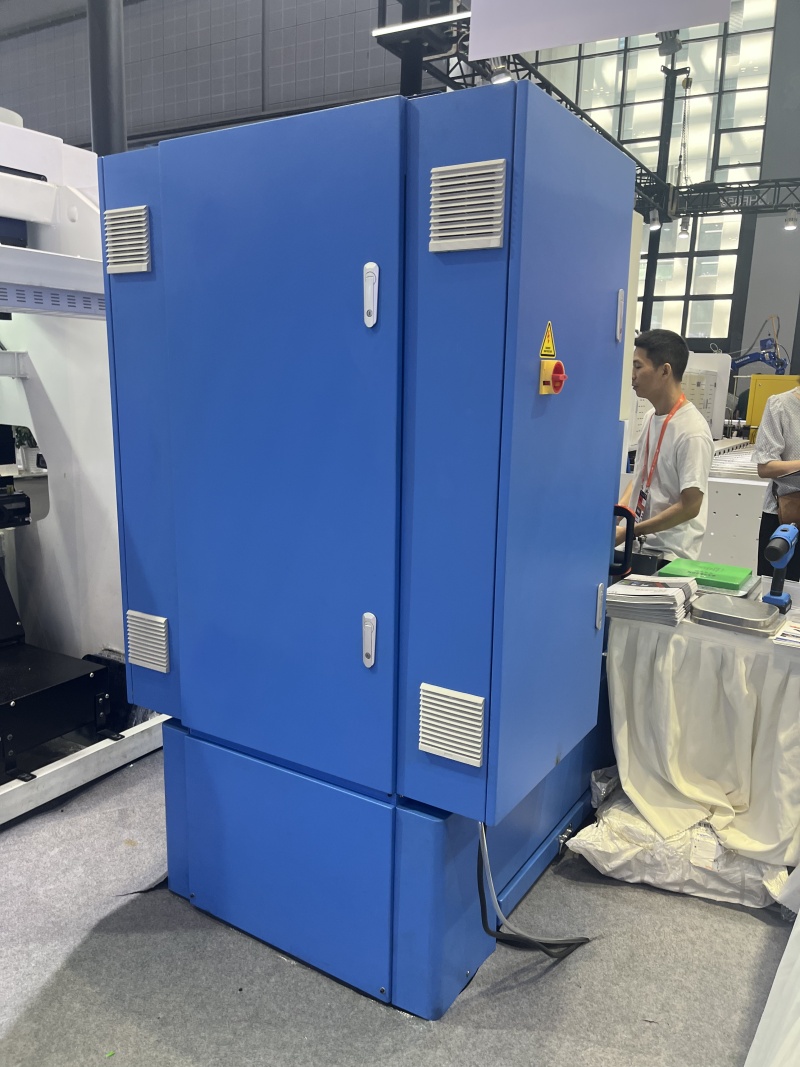

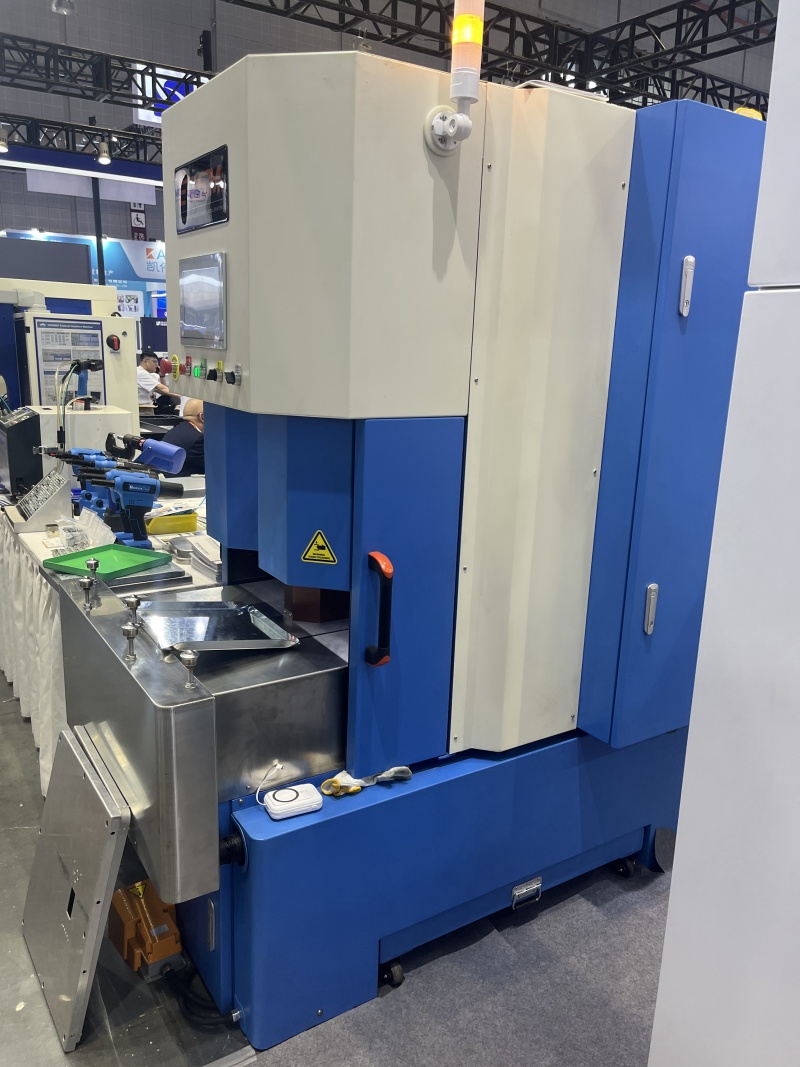

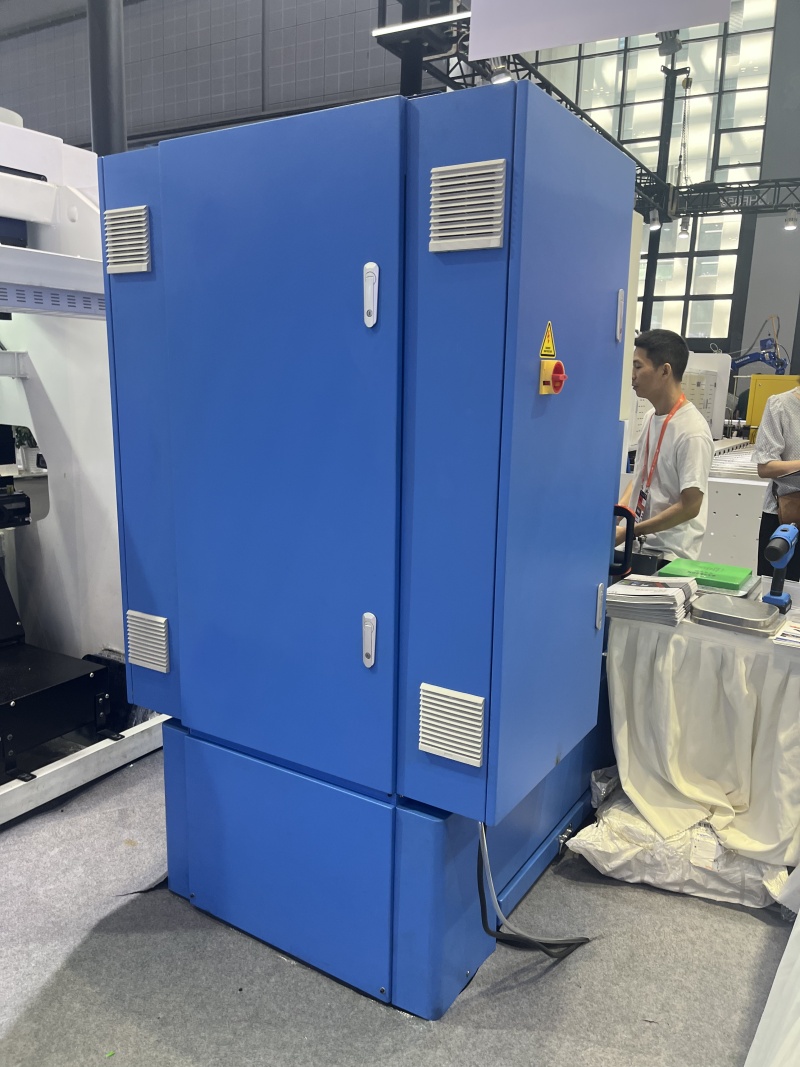

The 3050 Corner Former Machine is an advanced and flexible corner forming device specifically designed for mechanical corner forming in a wide variety of formable materials. This machine is highly efficient, requiring no welding or grinding, making it ideal for both small workshops and large-scale production environments.

Key Features and Advantages:

Flexible and Efficient Corner Forming:

Corner forming cycle time: The device can complete corner rounding and cutting in approximately 8 seconds.

Processing time for door frames (500mm x 500mm): From corner forming to ready-for-painting takes around 52 seconds.

Ideal for flexible production environments with frequent changes in production demands, suitable for both workshops and large-scale production.

Strong Adaptability:

Adjustable tool design: Enables quick and easy corner forming on doors and panels of various sizes. This versatility is highly beneficial for manufacturers with frequently changing production specifications.

Suitable for road sign manufacturers, enabling corner rounding on rectangular, square, triangular, and octagonal signs.

Supported Materials:

Mild steel (0.5mm - 5.0mm): Including galvanized, pre-coated, and plastic-covered materials.

Aluminum (1.2mm - 5.0mm).

Stainless steel (0.5mm - 3.0mm).

High-Speed Production:

For large-scale production, the 3050 Corner Former Machine offers high-speed corner forming, equipped with customer-specific fixed tool designs, optimizing cycle times and increasing throughput.

Robot Integration: The machine can connect to linear or robotic arm systems, ensuring seamless integration with automated production lines.

Special Features:

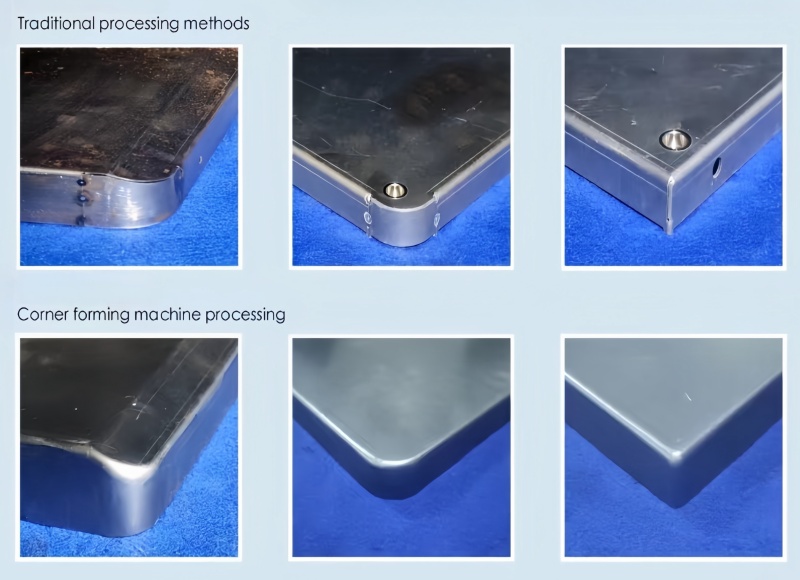

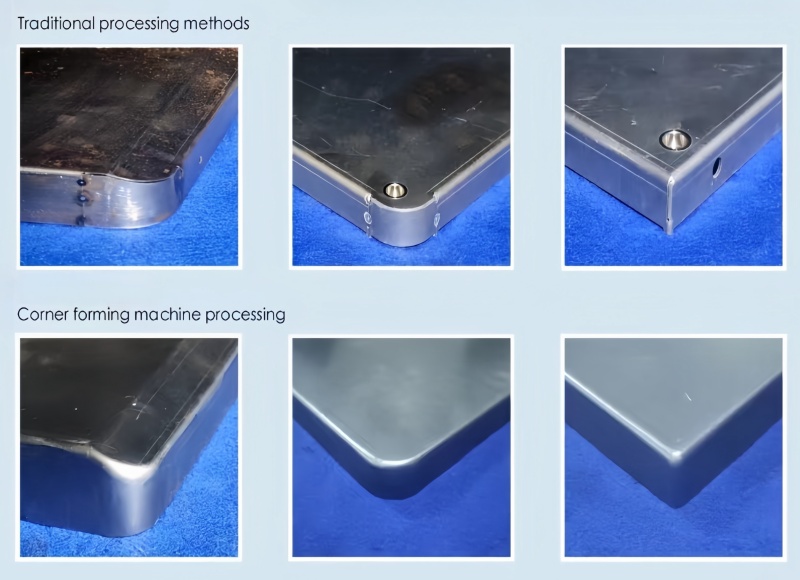

No welding or grinding required: The corner forming process eliminates the need for welding and grinding, simplifying the production process and enhancing production efficiency.

Tool versatility: With quick manual tool changes, the machine can efficiently handle various corner thicknesses and flange heights.

Adaptable to different part sizes: The machine supports various part sizes, providing nearly unlimited production possibilities without the need for expensive press tools.

Special Models:

Application Areas:

Suitable for corner forming in both workshops and large-scale sheet metal production.

Ideal for road sign manufacturers for corner rounding on various shaped signs.

Well-suited for large-scale door and panel production, particularly in scenarios requiring high-speed, repetitive production.

The 3050 Corner Former Machine series offers a fast and flexible corner forming solution in sheet metal processing, capable of replacing traditional welding and grinding processes, greatly improving production efficiency.