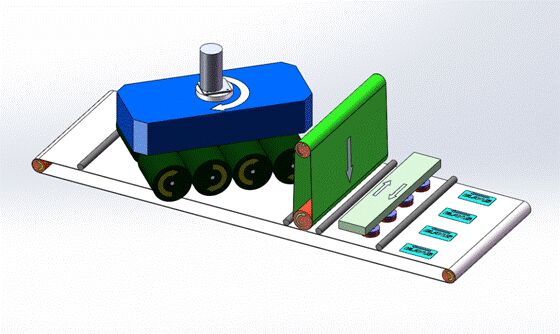

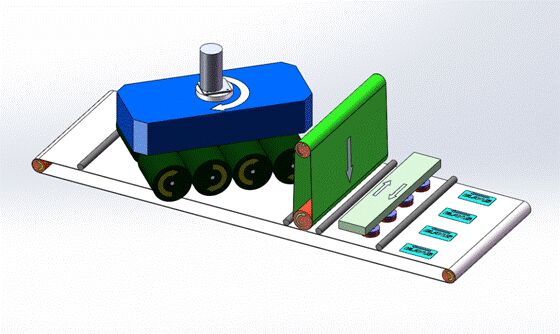

Sheet Metal Deburring Machine for Edge Rounding and Heavy Slag Removal of Support Structures for Various Equipment

This deburring machine is specially designed for sheet metal deburring, edge rounding, and heavy slag removal, making it ideal for use in the fabrication of support structures for various equipment, including steel pipeline support systems, platforms, catwalks, lattice towers, and other steel-based structures. The machine is engineered to provide high-quality finishing, removing burrs, slag, and ensuring smooth edges for steel plates, profiles, and fabricated metal components used in heavy equipment and structural applications.

Working Principle:

The machine employs a multi-stage process utilizing three key components that combine abrasive disc brushing, sanding belts, and omni-directional roller brushes. This design ensures thorough and precise deburring, rounding, and slag removal from the edges, holes, and surfaces of the workpieces. It is particularly effective for removing burrs caused by common industrial processes such as drilling, punching, laser cutting, plasma cutting, and flame cutting.

Technical Parameters:

| Parameter | Value |

| Processing Width | ≤ 800mm |

| Processing Thickness | 0.5 - 80mm |

| Minimum Processing Size | 50mm x 50mm (Carbon Steel) |

| Overall Power | 20.25 KW |

| Hammer Disc Brush Size | Φ 162mm |

| Sanding Belt Size | Φ 3530mm x 80mm (60# Zirconia Alumina) |

| Omni-Directional Brush Size | Φ 300mm x 300mm (120# Brush, German Künzeb) |

| Conveyor Speed | 0.5 - 6 m/min (Variable Frequency) |

| Sanding Belt Speed | 12 m/s |

| Roller Brush Rotation Speed | 8 - 26 m/s (Variable Frequency) |

| Roller Brush Planetary Speed | 1 - 15 rpm (Variable Frequency) |

| Roller Brush Axle Heads (Planetary) | 1 (Planetary Rotation) |

| Roller Brush Axle Heads (Self-Rotation) | 4 (Self-Rotation) |

| Thickness Adjustment Precision | 0.01mm |

| Roller Brush Compensation Precision | 0.01mm |

| Grinding Consumables | Hammer Disc Brush + Sanding Belt + Roller Brush |

| Work Table Load Capacity | ≤ 400kg |

| Dust Extraction Flow | 5000 m³/h |

| Machine Dimensions | Length: 4100mm, Width: 1900mm, Height: 2200mm |

| Machine Weight | Approx. 3T |

Processing Flow:

Hammer Disc Brush Station:

The hammer disc brush strikes the surface of the workpiece to remove slag and debris from edges and holes.

This station removes coarse burrs and larger particles that may be attached to the metal surface during fabrication processes.

Sanding Belt Station:

The sanding belt smooths out the residual burrs and finishes the metal surface.

The belt is composed of high-performance abrasive materials such as Zirconia Alumina, which ensures efficient deburring and fine surface polishing.

Omni-Directional Brush Station:

The omni-directional brush station is composed of four sets of rotating brush discs that perform high-speed centrifugal polishing.

The omni-directional brushes ensure uniform deburring of edges and holes, providing consistent R-edges without affecting the dimensions of the metal components.

Key Features:

Edge Rounding and Burr Removal: Effectively removes burrs, sharp edges, and slag, creating smooth, rounded edges with a controlled R-curve radius, which is customizable based on the material and the desired finish.

No Damage to Workpiece Dimensions: The machine is designed not to affect the dimensional accuracy of the workpiece. It only focuses on deburring and edge finishing, ensuring that precise measurements are maintained.

Independent Station Operation: Each of the stations (Hammer Disc Brush, Sanding Belt, and Omni-Directional Brush) can operate independently for specific tasks, such as:

Hammer Disc Brush for slag removal from edges

Sanding Belt for surface finishing and deburring

Omni-Directional Brushes for 360° deburring of edges and holes, ensuring thorough cleaning, especially for laser-cut and CNC-punched parts.

High Flexibility for Custom Parts: The system is highly flexible and capable of handling different types of steel, aluminum, and non-ferrous materials. It is particularly useful for processing complex-shaped components, including profiled structures and support beams.

Benefits for Support Structure Manufacturing:

High-Volume Processing: Continuous-feed operation ensures that bulk orders for steel components, platform supports, and other structures can be processed efficiently without compromising quality.

Enhanced Surface Finish: The system guarantees superior surface treatment compared to manual methods, ensuring that each piece has a uniform finish and smooth edges.

Cost-Efficiency: The machine reduces the need for manual labor, which significantly lowers processing costs, making it a cost-effective solution for large-scale fabrication and assembly operations.

Improved Safety: The dust extraction system ensures a clean and safe work environment, which is crucial in the fabrication of heavy structures where metal dust can pose safety risks.

Special Applications:

Support Structures for Equipment: Suitable for processing steel pipe racks, lattice towers, gantries, catwalks, and platform supports, which require high-quality deburring and edge finishing.

Customized Workpieces: The system is ideal for processing non-standard, custom-designed, or complex-shaped parts, such as mounting brackets, beam supports, and other steel components used in large machinery or structural applications.

Laser-Cut and Punching Parts: Particularly useful for laser-cut parts and CNC-punched metal sheets, where accurate burr removal and uniform edge rounding are critical for assembly and welding.

Dust Control and Environmental Benefits:

The machine includes a wet dust extraction system that collects metal dust during processing. The system uses high-pressure fans and a water mist filtration process to capture and absorb the dust, ensuring a safe and environmentally friendly workspace.

The filtration system also helps recycle metal dust, contributing to a more eco-friendly production process.