Introduction to the 1000kg Metal Plate Vacuum Lifter: Electric Vacuum Lifter for Sheet Metal in Laser Cutting and Metal Processing Equipment

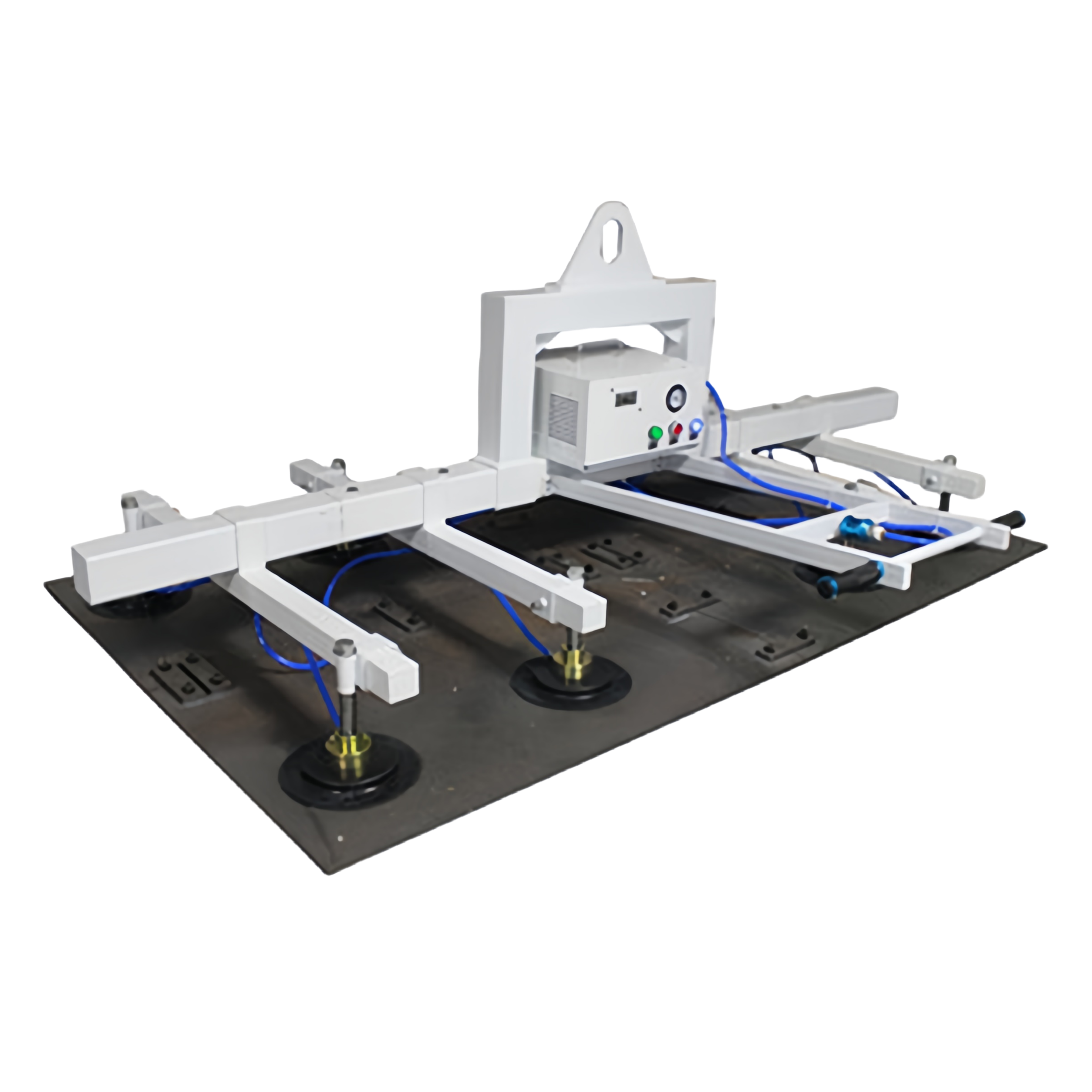

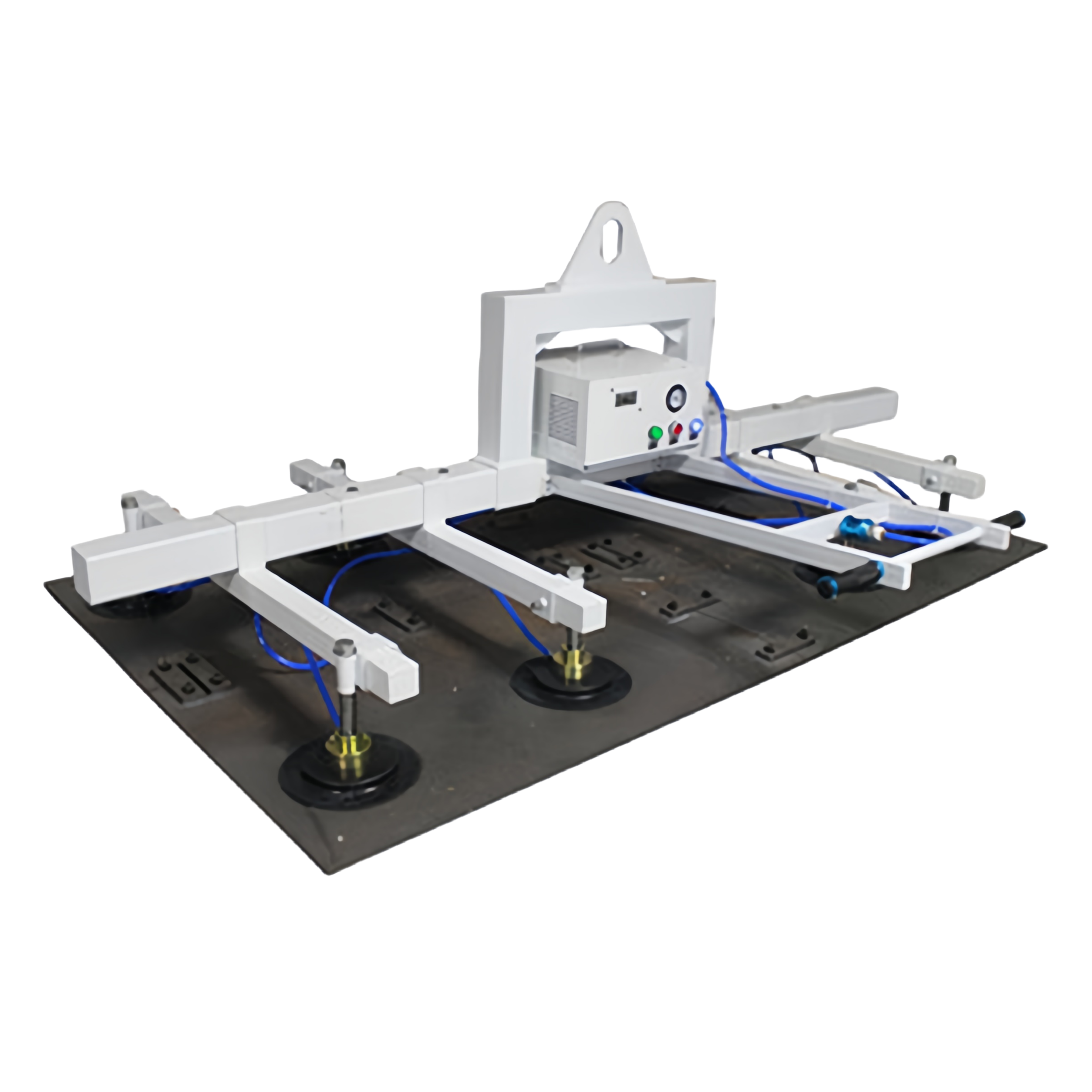

The 1000kg Metal Plate Vacuum Lifter is a state-of-the-art lifting solution designed specifically for the industrial handling of heavy metal plates, such as those used in laser cutting machines, punching presses, and other metal processing equipment. With an impressive lifting capacity of up to 1000kg, this electric vacuum lifter is an essential tool for optimizing material handling processes in factories and production lines where precision, efficiency, and safety are of paramount importance.

This model combines DC12V rechargeable battery technology with vacuum lifting principles to offer a powerful yet ergonomic solution for the lifting and transportation of sheet metal, steel plates, and other heavy materials. Its robust features and ease of use make it an indispensable tool for industries such as metal fabrication, automotive manufacturing, construction, and metalworking.

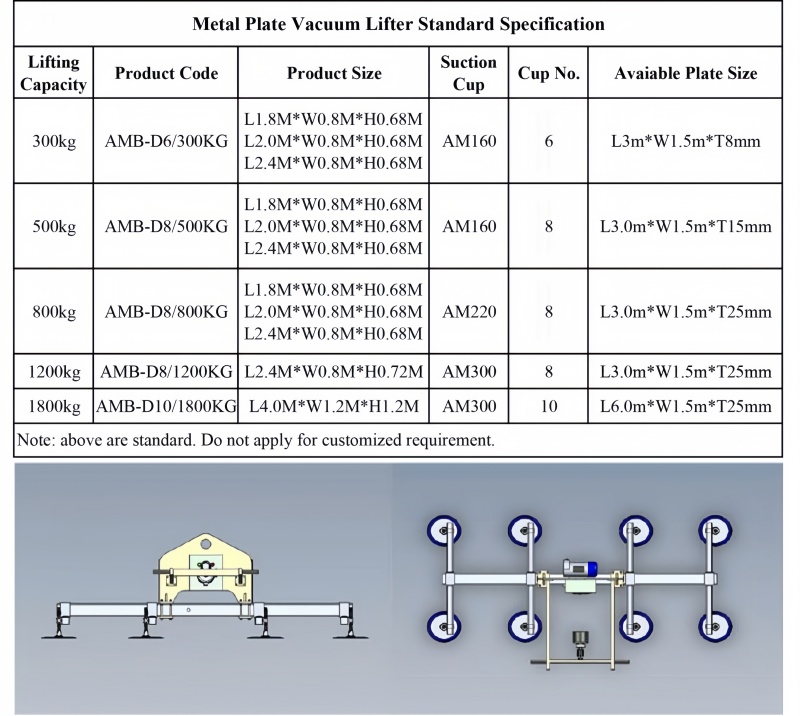

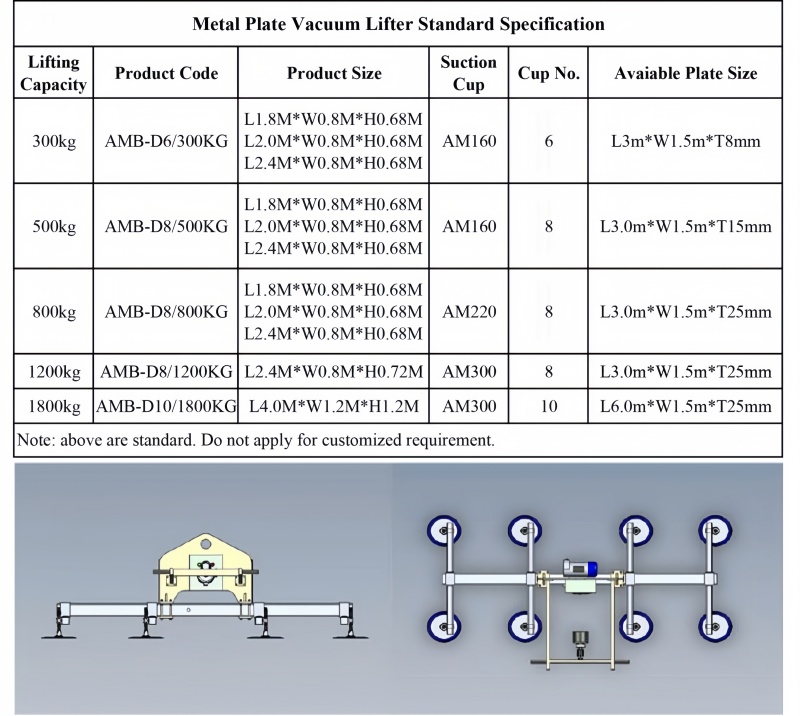

| Product Type | Rechargeable Lifter | Plug-in Lifter |

| Model | JS-J1000-5M | JS-J2000-5M | JS-C1000-25M | JS-C2000-5M |

| Rated Load (kg) | 1000 | 2000 | 1000 | 2000 |

| Suction Cup Diameter (mm) | 200 | 200 | 200 | 200 |

| Number of Suction Cups | 12 | 12 | 12 | 12 |

| Dimensions (mm) | 5000*1000 | 5000*1000 | 5000*1000 | 5000*1000 |

| Plate Size (mm) | 6000*2000 | 6000*2000 | 6000*2000 | 6000*2000 |

| Operating Power (V) | DC12V | DC12V | AC220V/380V | AC220V/380V |

Key Features of the 1000kg Metal Plate Vacuum Lifter

1. High Load Capacity (1000kg)

One of the key advantages of this electric vacuum lifter is its impressive load capacity of up to 1000kg. Whether you’re dealing with large steel plates, aluminum sheets, or other heavy materials, this vacuum lifter can handle the most demanding lifting tasks with ease. In industries like metalworking and construction, where large metal sheets are common, having a reliable system for safely moving these heavy materials is critical.

By using vacuum technology, this lifter ensures that metal plates are securely held without the risk of damage or slippage, even under heavy loads. This capability helps improve efficiency and reduce the risk of workplace accidents associated with manual lifting.

2. DC12V Rechargeable Battery Operation

The DC12V rechargeable battery is an innovative feature that enhances the lifter’s portability and flexibility. Unlike traditional systems that rely on external power sources, the 12V rechargeable battery allows the lifter to be used independently in remote areas or in places without immediate access to power outlets.

This battery-powered design means the lifter can be quickly moved between different locations within a factory or production environment without the need for additional electrical infrastructure. The long-lasting battery ensures that it can operate through multiple lifting cycles before requiring a recharge, making it highly suitable for high-efficiency operations.

Additionally, the charging system is easy to use and can be conveniently integrated into any workstation or charging station within the facility.

3. Vacuum Lifting Technology for Safe and Secure Handling

At the core of this lifter’s functionality is vacuum lifting technology, which provides a strong and secure grip on metal sheets, even under heavy loads. The lifter is equipped with high-quality suction pads that create a tight seal on the surface of the metal, allowing for safe handling without causing any damage, scratches, or dents to the material.

Adjustable Suction Pads: The suction cups are adjustable to accommodate different sizes and thicknesses of sheet metal, making the lifter versatile and adaptable for various industrial needs.

High Suction Power: The vacuum system ensures a consistent and reliable grip on materials, even when lifting heavy metal plates up to 1000kg.

This vacuum lifting method ensures precise positioning and safe transport of materials from one point to another, minimizing the risk of dropped loads or damage during movement.

4. Ergonomically Designed for Worker Safety

Handling heavy metal sheets can cause significant strain on workers, leading to musculoskeletal injuries and accidents. The 1000kg Metal Plate Vacuum Lifter is designed with ergonomics in mind to alleviate the strain of manual lifting.

Lightweight and User-Friendly: Despite its powerful lifting capacity, the vacuum lifter is lightweight and easy to maneuver. The ergonomic handle and simple controls allow operators to move heavy metal plates without overexerting themselves.

Reduces Manual Labor: The lifter significantly reduces the need for manual lifting, ensuring that operators can handle large sheets of metal without excessive physical effort. This leads to increased productivity and reduced risk of injury.

Precise Handling: With the lifter’s precise control system, workers can safely lift, position, and transport metal sheets with minimal effort, allowing for a more efficient workflow.

5. Energy-Efficient and Cost-Effective

The DC12V rechargeable battery system is not only convenient but also energy-efficient. It eliminates the need for external power supplies or compressed air systems, making it a more cost-effective solution compared to other lifting equipment. The battery-powered lifter is also more environmentally friendly, as it reduces the reliance on traditional energy sources, lowering operating costs and minimizing environmental impact.

The rechargeable battery is designed for easy maintenance and long service life, reducing downtime and ensuring that the system remains operational for longer periods, which enhances overall efficiency.

6. Versatile Applications in Metal Processing

The 1000kg Metal Plate Vacuum Lifter is highly versatile and can be used in a range of metal processing applications. Some of the most common industries and tasks where this lifter excels include:

Laser Cutting and Metal Fabrication: The vacuum lifter can easily move large metal sheets from the laser cutting machines to other processing stations, such as punching, bending, or welding. Its ability to handle sheets with precision ensures that the cut parts are moved safely without being damaged.

Sheet Metal Handling: This lifter is ideal for sheet metal handling in industries where large sheets of steel, aluminum, or other materials need to be moved frequently. It helps streamline the workflow by reducing manual handling and improving handling speed.

Automotive Manufacturing: In automotive manufacturing, large metal sheets are often used in the production of vehicle parts. The vacuum lifter facilitates the easy transport of these sheets between different stages of production.

Construction and Building: The lifter is also valuable for construction projects, where large metal panels are used for facades, roofing, or other applications. It allows construction workers to safely handle and move heavy panels to different areas of the site.

7. Safety Features

The 1000kg Metal Plate Vacuum Lifter comes equipped with several safety features to ensure the secure handling of heavy materials and protect operators:

Vacuum Pressure Monitoring: A built-in system continuously monitors the vacuum pressure, ensuring that the lifting pads maintain a strong and secure grip. If the pressure drops below safe levels, the system triggers an alarm to alert the operator.

Automatic Locking Mechanism: Once the metal plate is lifted, the vacuum lifter automatically locks the suction cups in place, preventing accidental detachment during transport.

Emergency Stop Function: In case of an emergency, the operator can quickly stop the vacuum lifter by pressing the emergency stop button, preventing accidents and ensuring safety at all times.

8. Low Maintenance and Durability

The 1000kg Metal Plate Vacuum Lifter is designed to require minimal maintenance. It uses high-quality materials that are durable enough to withstand the harsh conditions of metal processing environments. The rechargeable battery is long-lasting, and the vacuum system is easy to clean and maintain, ensuring that the lifter remains operational for long periods without significant downtime.

Applications of the 1000kg Metal Plate Vacuum Lifter

This electric vacuum lifter is perfect for various industries that rely on the handling and transport of heavy metal plates. Key applications include:

Metal Processing: For lifting and moving metal sheets and plates between cutting, punching, bending, and welding stations.

Automotive Manufacturing: Handling large sheets of metal used in car body assembly.

Construction: Transporting large metal panels for building facades or industrial installations.

Fabrication and Assembly: Used for lifting metal plates during the fabrication and assembly process in warehouses and production plants.

Laser Cutting: Handling cut metal sheets produced by laser cutting machines.