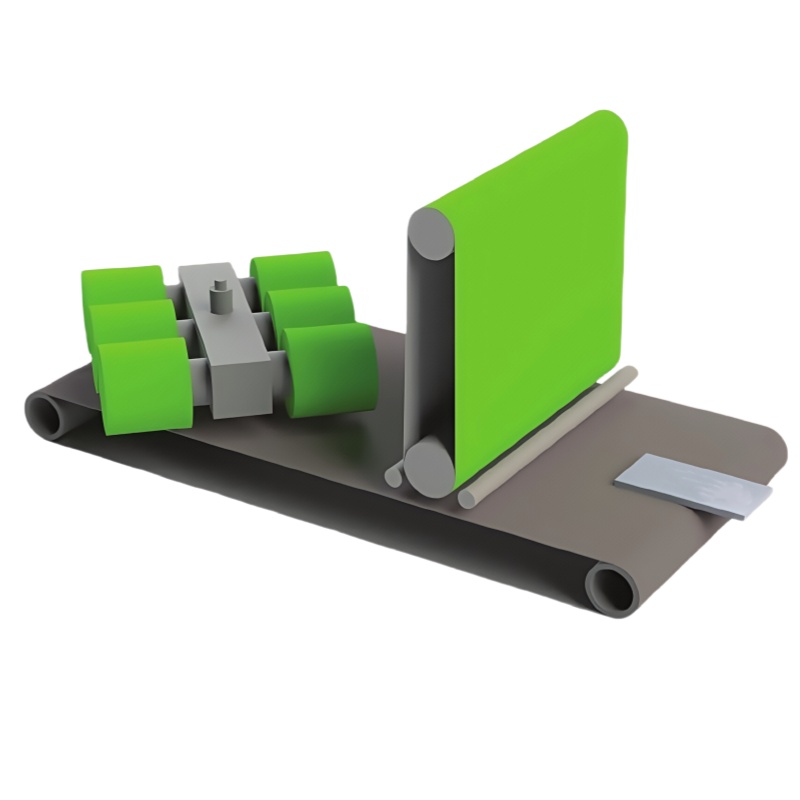

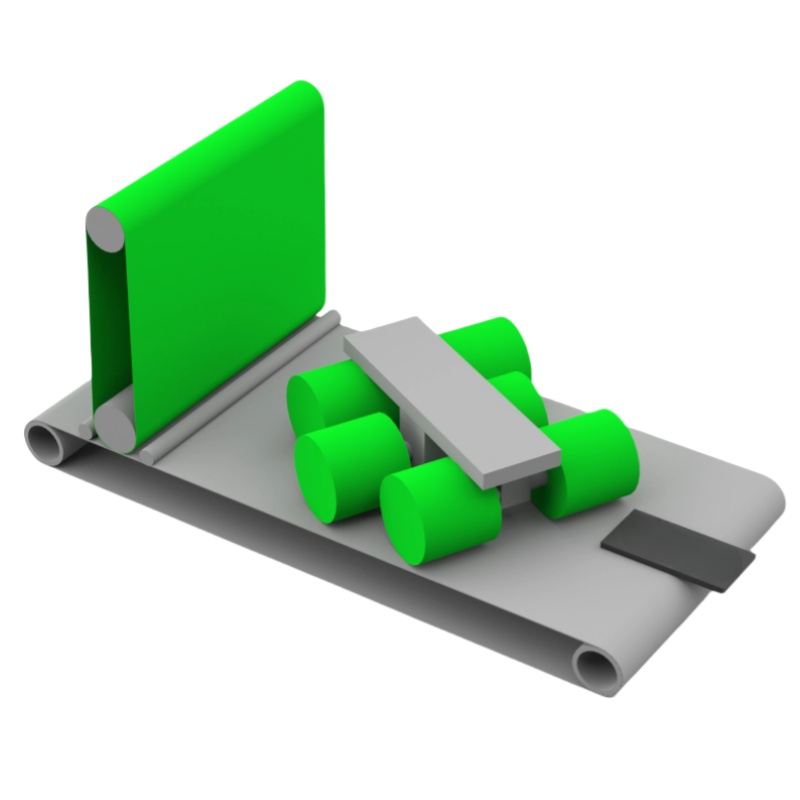

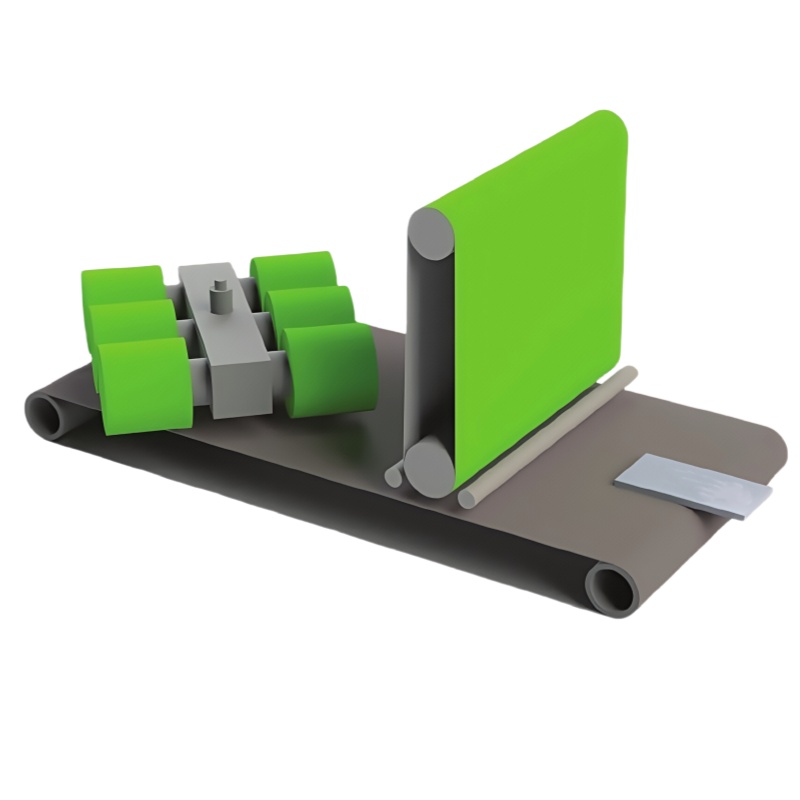

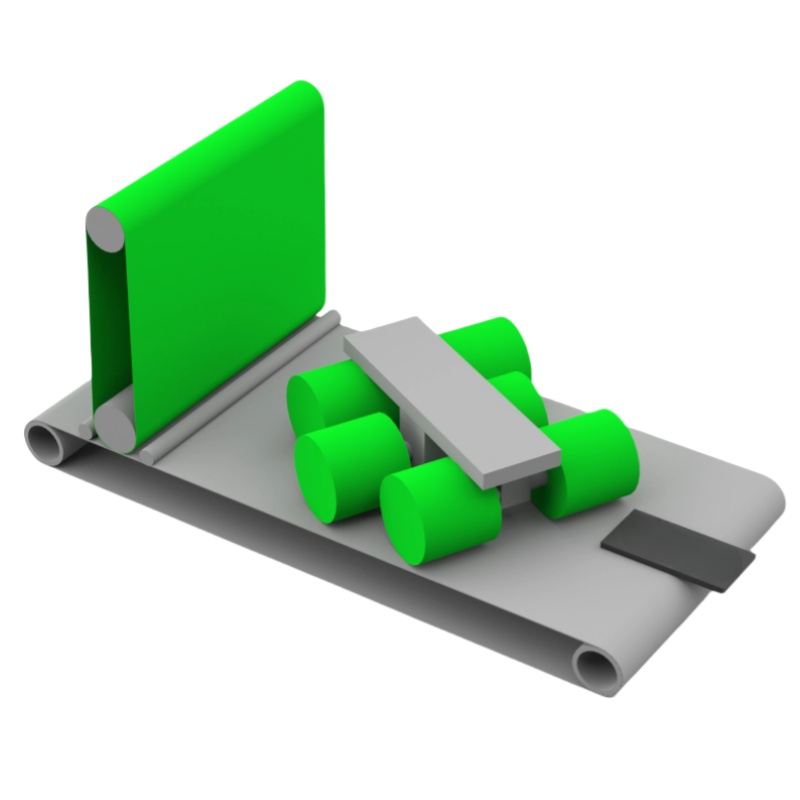

1000mm Industrial Sanding Machine for Deburring, Edge Rounding, and Oxide Removal for Smooth, Clean Metal Parts

The 1000mm Industrial Sanding Machine is a robust and versatile solution designed to efficiently handle deburring, edge rounding, and oxide removal for smooth, clean metal parts. This machine is ideal for various industrial applications where high-quality surface finishing is essential. Whether dealing with laser-cut, plasma-cut, or waterjet-cut parts, this sanding machine offers exceptional performance in delivering consistent, professional results.

Key Features:

Wide Working Width (1000mm):

With a working width of 1000mm, this machine can process large metal sheets and parts in a single pass. It is designed to handle medium to large production volumes efficiently, making it suitable for high-output environments such as metal fabrication shops and manufacturing plants.

Effective Deburring and Edge Rounding:

The deburring station is equipped with high-quality abrasive belts that help remove burrs and sharp edges from laser-cut, plasma-cut, waterjet-cut, and punched metal parts. This ensures the parts are free from imperfections and meet industry standards for safety and quality.

The edge rounding function provides a uniform radius on metal edges, ensuring smooth and clean edges that enhance both the aesthetic and functional properties of the parts.

Oxide Removal:

For parts that have been subjected to heat-based processes (e.g., laser cutting), the machine includes an oxide removal feature. The oxide layer that forms on the surface can interfere with further processing or assembly. The machine's sanding mechanism efficiently removes this oxide layer, ensuring a clean and smooth surface.

Rotary Brush Station:

The rotary brush station further enhances the cleaning process by polishing and ensuring uniform surface treatment. The brushes rotate around the workpiece, removing remaining burrs and providing a fine finish, all while reducing the risk of surface damage.

Abrasive Belt Station:

The abrasive belt station handles the heavy-duty deburring and smoothing process. This station uses an abrasive belt to efficiently remove sharp edges, rough spots, and oxidation, leaving a clean surface ready for further assembly or finishing.

Variable Speed and Adjustable Settings:

Heavy-Duty Construction:

Built for industrial use, the 1000mm Industrial Sanding Machine features a durable frame that can withstand continuous operation in demanding production environments. Its sturdy design ensures longevity and consistent performance over time, even under heavy use.

Versatile Material Compatibility:

This sanding machine is designed to process a wide range of materials, including stainless steel, aluminum, carbon steel, and other non-ferrous metals. It is ideal for industries such as automotive, aerospace, metalworking, and construction.

Dust Extraction System:

High Efficiency and Precision:

This machine is engineered for high-efficiency processing with precise control over the deburring, edge rounding, and oxide removal processes. It delivers consistent, high-quality finishes on metal parts, minimizing the need for manual labor and reducing the potential for defects.

Applications:

Deburring of laser-cut, plasma-cut, waterjet-cut, and punched metal parts.

Edge rounding for a smooth, clean radius on metal edges.

Oxide removal for laser-cut parts or other heat-treated metal parts.

Surface finishing to improve the appearance and functionality of metal components.

Benefits:

Enhanced Metal Part Quality: Achieves clean, smooth edges and surfaces, eliminating sharp edges and imperfections.

Increased Efficiency: The machine can handle large metal parts and high-volume production runs with ease.

Versatile: Capable of processing a variety of materials, including steel, aluminum, and other metals.

Adjustable Settings: Flexible controls allow for tailored processing based on the specific material and finish requirements.

Reduced Labor Costs: Automated processing significantly reduces the need for manual deburring, saving time and labor costs.

Conclusion:

The 1000mm Industrial Sanding Machine is an essential tool for deburring, edge rounding, and oxide removal in industrial metal processing. With its high-performance sanding and rotary brush systems, adjustable settings, and versatile material compatibility, this machine ensures that metal parts are finished to the highest standards. Whether processing laser-cut, plasma-cut, waterjet-cut, or punched parts, it provides an efficient, cost-effective solution for achieving smooth, clean, and professional metal components ready for further use.

Applications:

Deburring of metal parts from various cutting methods.

Edge rounding for improved safety and appearance.

Oxide removal for laser-cut parts and other heat-treated metal.

Surface finishing to ensure the quality and consistency of parts.