1000mm Sheet Metal Deburring Machine for Sale

Heavy-Duty Deburring | Edge Rounding | Oxide Removal | Surface Finishing

Engineered for high-volume metal processing with consistent, professional results.

Product Overview

This 1000mm sheet metal deburring machine is designed to meet the rigorous demands of modern metalworking environments. It offers automated, high-speed deburring, edge rounding (up to 2mm radius), and oxide film removal for medium to large-format sheet metal components.

Built for laser-cut, punched, sheared, or plasma-cut parts, this machine handles carbon steel, stainless steel, aluminum, copper, and various non-ferrous metals with ease.

⚙️ Key Features & Capabilities

Working Width: 1000mm

Perfect for larger parts, maximizing productivity per pass.

Multi-Function Design:

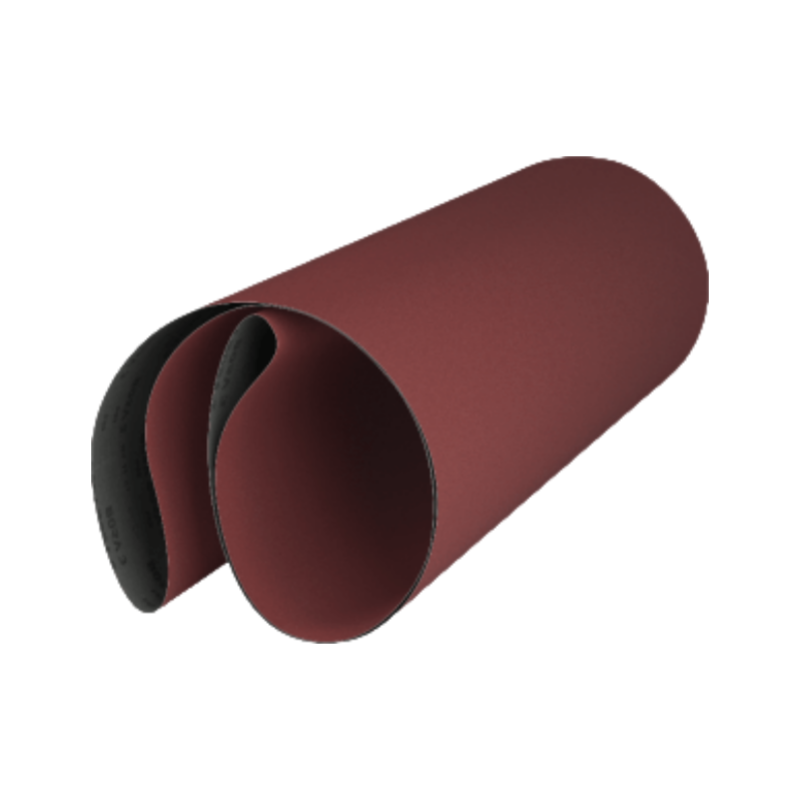

Abrasive Belt + Brush Combination:

Sand belt station removes large burrs and slag

Rotating brush station rounds edges, finishes contours

High-Precision Adjustments:

Dust Collection Interface:

Equipped with a dust extraction port; connect to vacuum or cyclone system for a clean workspace.

Technical Specifications (example configuration)

| Specification | Value |

| Working Width | ≤ 1000mm |

| Processing Thickness | 0.5mm – 80mm |

| Min Part Size | 50 × 50mm |

| Abrasive Belt Size | Φ1910mm × 1050mm |

| Brush Size | Φ300mm × 300mm |

| Feed Speed | 0.5 – 6 m/min (adjustable) |

| Brush Speed | 500 – 1400 rpm |

| Brush Public Speed | 1 – 15 rpm |

| Main Power | 36.5 kW |

| Dust Air Volume | ≥ 5000 m³/h |

| Machine Dimensions | 3050 × 2150 × 2150mm |

| Weight | ~3 Tons |

Applications

Laser-cut sheet metal (SS, CS, Alu, etc.)

Plasma/flame-cut parts

Stamped and punched components

Welding edge prep

Oxide film and scale removal

Edge rounding for powder coating and safety

✅ Why Choose This Machine?

One-pass Processing for high productivity

Cleaner Edges improve coating adhesion & handling safety

Cost-Effective vs. manual labor or rework

⚙️ Customizable Configurations (1–5 heads, optional vacuum bed, etc.)

Environmentally Friendly with optional integrated dust collection