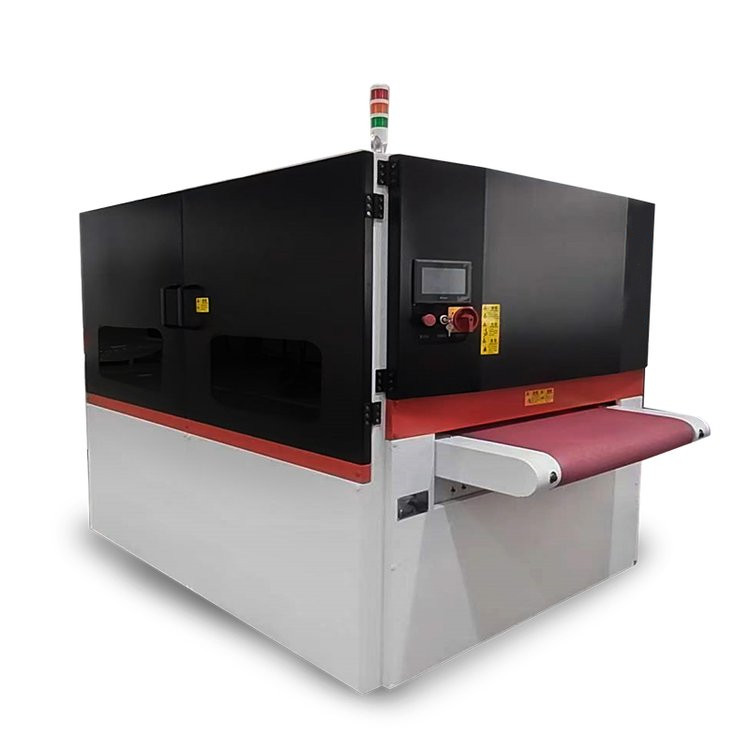

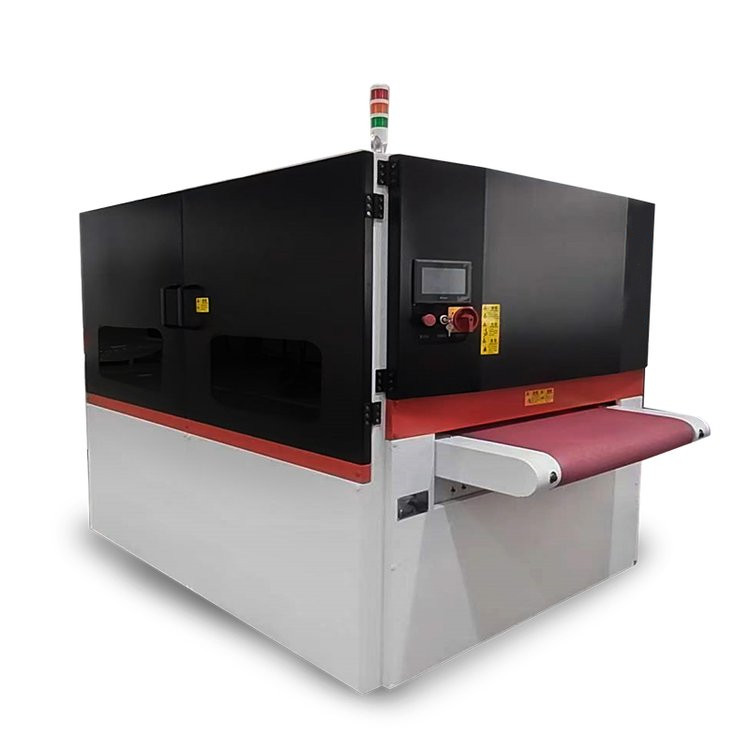

Edge Rounding Machine – 1350mm

The Edge Rounding Machine is designed to round sharp edges of metals like steel, aluminum, and stainless steel. The rounded edges ensure safety by reducing sharp edges, which is essential in preventing injuries during handling. This machine also promotes better paint adhesion during the post-processing phase, making it ideal for industries requiring high-quality finishing.

Key Features & Benefits

✅ Edge Rounding – Smooths sharp edges to improve safety and handling

✅ Deburring – Effectively removes burrs and sharp edges from metal parts

✅ Material Compatibility – Works with steel, aluminum, and stainless steel

✅ Wide Processing Range – Suitable for metal thicknesses from 0.5mm to 80mm

✅ High Throughput – Conveyor speed of 0.5–6.0 m/min ensures efficient operation

✅ Magnetic & Vacuum Holding System – Securely holds the parts for precise processing

✅ Heavy-Duty Capacity – Handles parts up to 1350mm wide and 600 kg

✅ 8 High-Efficiency Flap Wheels – For consistent and uniform edge rounding across large surfaces

✅ Dust Extraction System – Requires a minimum of 4000 m³/h airflow to maintain clean working conditions

✅ Customizable Conveyor Speed – Adjust from 0.5 to 4.0 m/min to suit different processing needs

Technical Specifications

| Feature | Specification |

| Material | Steel, Aluminum, Stainless Steel |

| Process | Edge Rounding |

| Material Thickness | 0.5 - 80 mm |

| Max. Material Width | 1350 mm |

| Min. Part Dimensions | 50 x 50 mm |

| Max. Material Weight | 600 kg |

| Conveyor Speed | 0.5 - 6.0 m/min |

| Minimum Deduster Need | 4000 m³/h |

| Machine Power - Consumption | 15.7 / 26.7 kW |

| Machine Weight | 3200 kg |

| Holder System | Magnetic (Vacuum Optional) |

| Flap Wheels Quantity | 8 |

| Flap Wheels Dimensions | Ø350 x 400 mm |

| Conveyor Width | 1300 mm |

| Working Height | 120 mm |

| Processes | Edge Rounding |

Applications

Metal Sheet Fabrication – Rounds edges on large sheets of steel, aluminum, and stainless steel

Paint Preparation – Enhances paint adhesion by smoothing edges

Occupational Safety – Ensures safe handling of metal parts by removing sharp edges

Industrial Manufacturing – Ideal for use in automotive, aerospace, and metal processing industries